At their core, Polytetrafluoroethylene (PTFE) seals reduce vehicle emissions by providing a superior and highly durable barrier against leakage. They prevent harmful fuel vapors, exhaust gases, and other fluids from escaping into the atmosphere by maintaining their integrity under the extreme conditions found in modern engines and drivelines.

The true value of PTFE in emissions control is not just its ability to seal, but its ability to do so consistently over the vehicle's entire lifespan. Its unique combination of chemical inertness, temperature stability, and low friction prevents the degradation that causes traditional seals to fail, ensuring a permanent solution to leakage-related emissions.

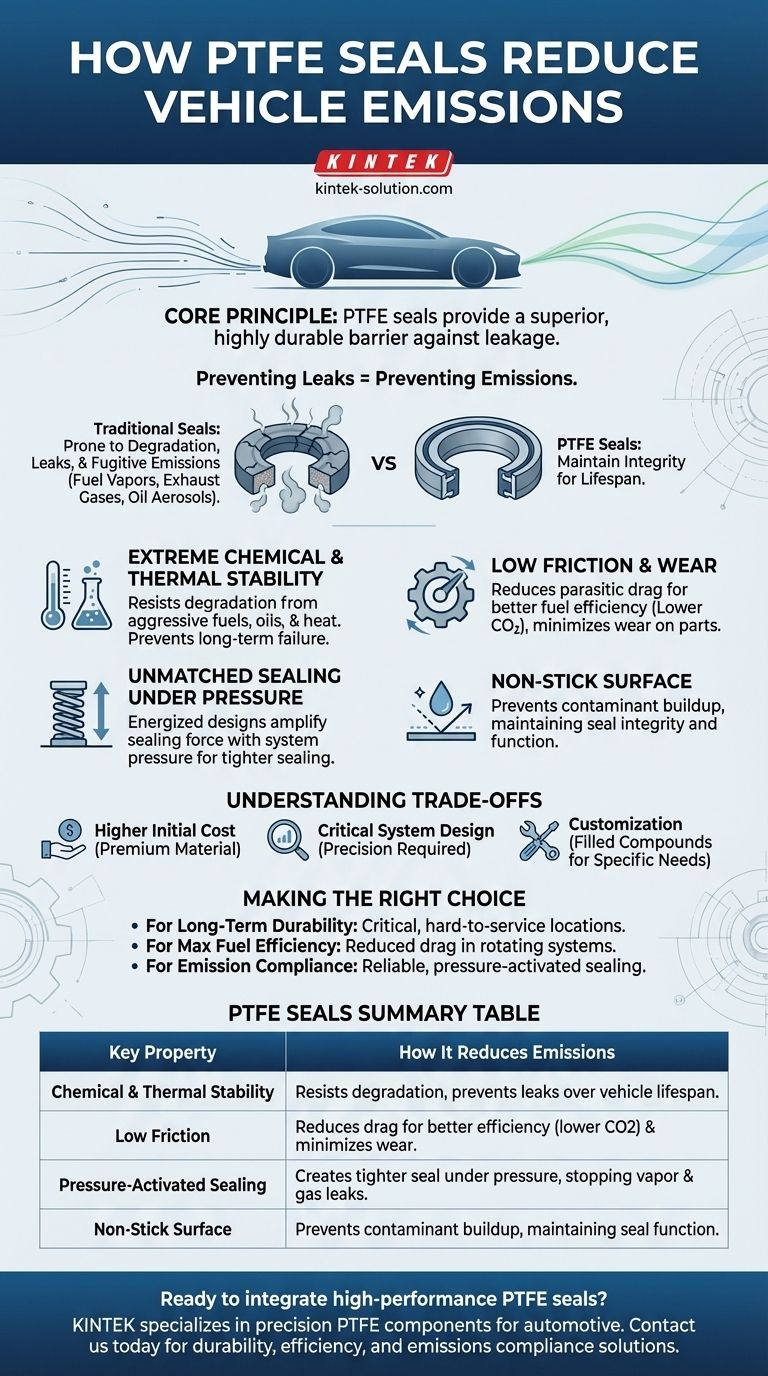

The Core Principle: Preventing Leaks is Preventing Emissions

A vehicle's systems rely on a sealed environment to operate efficiently and cleanly. Any breach in this system, no matter how small, can directly contribute to pollution.

The Direct Link Between Sealing and Emissions

Leaking seals are a primary source of fugitive emissions. This includes the escape of unburned fuel vapors (hydrocarbons), oil aerosols, and hot exhaust gases, all of which are regulated pollutants that contribute to air quality degradation.

Why Traditional Seals Can Fall Short

Many conventional elastomer (rubber) seals can harden, crack, or degrade when exposed to aggressive fuels, oils, and the high temperatures of an engine bay. This material breakdown inevitably leads to leaks, compromising the vehicle's emissions performance over time.

Key PTFE Properties That Drive Emission Reduction

The effectiveness of PTFE seals stems directly from the fundamental properties of the material itself. These characteristics allow them to succeed where other materials may fail.

Unmatched Sealing Under Pressure

Many PTFE automotive seals are energized designs, featuring a spring or elastomer element inside the PTFE jacket. This energizer provides an initial sealing force, which is then massively amplified by system pressure, creating an even tighter seal when it's needed most.

Extreme Chemical and Thermal Stability

PTFE is virtually inert to all automotive chemicals, including modern synthetic oils, aggressive fuel additives, and exhaust fluids. It also withstands extreme temperatures without losing its sealing capability, ensuring it does not degrade from heat cycling.

The Impact of Low Friction

PTFE has one of the lowest coefficients of friction of any solid material. This property dramatically reduces wear and tear on both the seal and the moving parts it touches. A seal that doesn't wear out doesn't leak, and the reduced friction also contributes to better overall fuel efficiency, lowering CO2 output.

Maintaining Integrity with a Non-Stick Surface

The non-stick nature of PTFE prevents contaminants like carbon and sludge from building up on the seal's surface. This self-cleaning characteristic ensures the seal remains fully functional and avoids the abrasive wear or functional blockage that debris can cause.

Understanding the Trade-offs

While highly effective, PTFE seals are not a universal drop-in replacement for every application. Their unique properties come with specific engineering considerations.

Higher Initial Material Cost

PTFE is a premium engineering material, and seals made from it are typically more expensive than their traditional elastomer counterparts. The investment is justified by their extended lifespan, reduced maintenance, and superior reliability.

Importance of System Design

The performance of a PTFE seal is highly dependent on the design of the hardware it is installed in. Factors like surface finish, clearances, and installation procedures are more critical than with forgiving elastomer seals to ensure a proper, leak-free fit.

Customization for Performance

Pure PTFE can be soft and prone to creep under load. For this reason, most high-performance seals use filled PTFE compounds, where materials like glass fiber, carbon, or bronze are added to enhance wear resistance, stiffness, and dimensional stability for a specific application.

Making the Right Choice for Your Goal

Selecting the right sealing technology is crucial for meeting performance and regulatory targets. The decision to use PTFE should be aligned with your primary engineering objective.

- If your primary focus is long-term durability: PTFE's resistance to chemical and thermal degradation makes it the definitive choice for critical, hard-to-service sealing locations.

- If your primary focus is maximizing fuel efficiency: The low-friction properties of PTFE seals reduce parasitic drag in rotating systems, contributing to meaningful gains in efficiency and lower CO2.

- If your primary focus is compliance with stringent emission standards: The reliable, pressure-activated sealing of energized PTFE provides the highest assurance against leaks of fuel vapors and other regulated fluids.

Ultimately, leveraging the unique material science of PTFE is a direct and reliable engineering strategy for building cleaner, more efficient, and more durable vehicles.

Summary Table:

| Key Property | How It Reduces Emissions |

|---|---|

| Chemical & Thermal Stability | Resists degradation from fuels, oils, and heat, preventing leaks over the vehicle's lifespan. |

| Low Friction | Reduces parasitic drag for better fuel efficiency (lower CO2) and minimizes wear to prevent failure. |

| Pressure-Activated Sealing | Energized designs create a tighter seal under pressure, stopping vapor and gas leaks effectively. |

| Non-Stick Surface | Prevents contaminant buildup, maintaining seal integrity and function in dirty environments. |

Ready to integrate high-performance PTFE seals into your automotive designs?

At KINTEK, we specialize in manufacturing precision PTFE components—including seals, liners, and labware—for the automotive, semiconductor, medical, and industrial sectors. Our expertise in custom fabrication, from prototypes to high-volume orders, ensures you get a sealing solution tailored to your specific needs for durability, efficiency, and emissions compliance.

Contact us today to discuss how our PTFE seals can help you build cleaner, more reliable vehicles.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Teflon Balls for Advanced Industrial Applications

People Also Ask

- What are the recommended processing parameters for CNC machining PTFE? Master Heat Control for Precision Parts

- What role does PTFE play in industrial equipment maintenance? Extend Lifespan & Reduce Downtime

- What efficiency benefits do PTFE lip seals provide in aerospace applications? Reduce Fuel Costs & Boost Reliability

- What factors influence the design variations of PTFE valves? Select the Perfect Valve for Your Application

- What are the advantages of using PTFE as the material for rotary shaft lip seals? Achieve Unmatched Reliability in Extreme Conditions

- Is Teflon always necessary for heat transfer applications? Weighing Protection vs. Precision

- What is the function of a teflon check valve in control systems? Prevent Backflow in Corrosive & High-Temp Processes

- What are the applications of Teflon in the automotive industry? Enhance Vehicle Performance & Durability