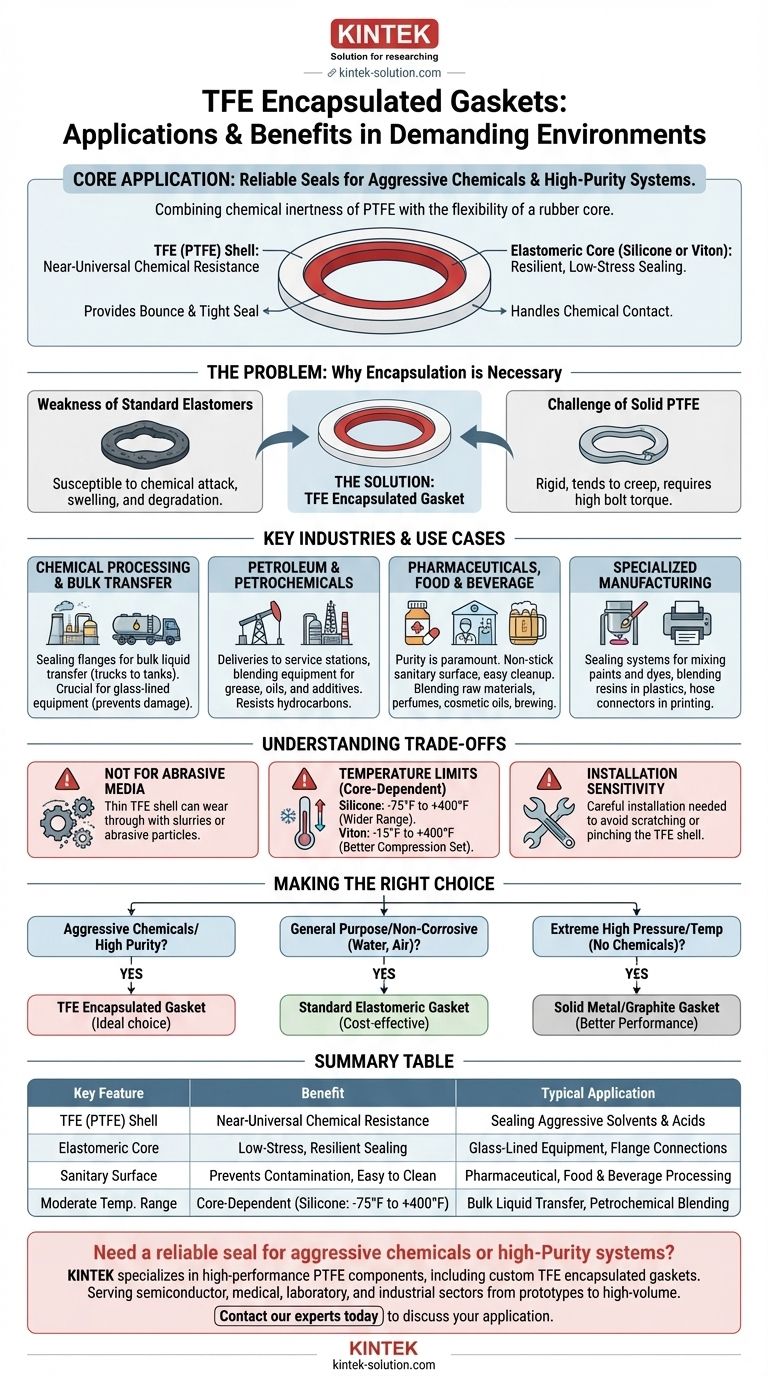

At their core, TFE encapsulated gaskets are used in demanding applications where a reliable seal is needed against aggressive chemicals or in high-purity systems. They are the go-to solution for sealing flanges and connections in chemical processing, bulk liquid transfer, and pharmaceutical manufacturing, effectively combining the chemical inertness of PTFE with the flexibility of a rubber core.

The central advantage of a TFE encapsulated gasket is its dual nature: it provides the near-universal chemical resistance of a PTFE shell while relying on an inner elastomeric core (like silicone or Viton) to deliver the resilient, low-stress sealing that solid PTFE gaskets lack.

The Problem: Why Encapsulation is Necessary

To understand the value of an encapsulated gasket, one must first understand the limitations of its constituent parts when used alone.

The Weakness of Standard Elastomers

Standard rubber gaskets provide excellent, flexible seals under low bolt loads. However, they are highly susceptible to chemical attack from aggressive solvents, acids, and industrial chemicals, leading to swelling, degradation, and eventual seal failure.

The Challenge of Solid PTFE

Solid PTFE (Teflon) is famously inert and resistant to nearly all chemicals. The problem is that it's a rigid material with a tendency to "creep" or deform permanently under pressure, meaning it doesn't spring back once compressed. This requires very high bolt torque to create a seal and makes it unsuitable for applications with pressure or temperature fluctuations.

The "Best of Both Worlds" Solution

An encapsulated gasket solves these problems by placing a soft, resilient elastomeric core inside a thin, protective shell of TFE (a type of PTFE, like FEP). The TFE shell handles the chemical contact, while the inner core provides the "bounce" needed to maintain a tight, reliable seal with much less force.

Key Industries and Specific Use Cases

This unique construction makes TFE encapsulated gaskets indispensable across several critical industries.

Chemical Processing & Bulk Transfer

This is the primary application domain. These gaskets are used extensively for sealing connections when transferring materials from trucks to storage tanks and from storage to the process area. They are also crucial for glass-lined equipment, where their ability to seal with low force prevents damage to the fragile flanges.

Petroleum and Petrochemicals

In the petroleum industry, these gaskets handle deliveries to service stations and are used in equipment for blending grease, oils, and mixing additives. Their resistance to a wide range of hydrocarbons and solvents is critical.

Pharmaceuticals, Food & Beverage

Here, purity is paramount. The non-stick, sanitary surface of the TFE shell prevents contamination and makes for easy cleanup. They are used for blending raw pharmaceutical materials, transferring perfumes and oils in the cosmetic industry, and in brewing applications.

Specialized Manufacturing

Other common uses include sealing connections in systems for mixing paints and dyes, blending liquids and resins in plastics manufacturing, and sealing hose connectors in industrial printing and marking equipment.

Understanding the Trade-offs

While highly effective, encapsulated gaskets are a specialized solution with specific limitations.

Not Suited for Abrasive Media

The thin TFE encapsulation is designed for chemical resistance, not physical abrasion. Slurries or fluids with abrasive particles can wear through the outer layer, compromising the seal and exposing the inner core.

Temperature Limits are Core-Dependent

The overall temperature rating of the gasket is dictated by its elastomeric core, not the TFE shell. A silicone core is suitable for a wider temperature range (e.g., -75°F to +400°F), while a Viton core offers better compression set but a narrower range (e.g., -15°F to +400°F).

Installation Sensitivity

The TFE shell is durable but not indestructible. Care must be taken during installation to ensure the flange surfaces are clean and to avoid scratching or pinching the gasket, which could create a leak path.

Making the Right Choice for Your Application

Selecting the correct gasket requires matching its capabilities to the operational demands of your system.

- If your primary focus is sealing aggressive chemicals or ensuring high purity: The near-universal chemical resistance and sanitary surface of a TFE encapsulated gasket make it the ideal choice.

- If your primary focus is general-purpose sealing of non-corrosive fluids like water or air: A standard, more cost-effective elastomeric gasket is likely sufficient.

- If your primary focus is extremely high pressure or temperature without aggressive chemicals: A solid metal or graphite gasket may provide better performance and creep resistance.

Ultimately, choosing a TFE encapsulated gasket is a strategic decision to ensure seal integrity in environments where other materials would quickly fail.

Summary Table:

| Key Feature | Benefit | Typical Application |

|---|---|---|

| TFE (PTFE) Shell | Near-universal chemical resistance | Sealing aggressive solvents & acids |

| Elastomeric Core | Low-stress, resilient sealing | Glass-lined equipment, flange connections |

| Sanitary Surface | Prevents contamination, easy to clean | Pharmaceutical, Food & Beverage processing |

| Moderate Temp. Range | Core-dependent (e.g., Silicone: -75°F to +400°F) | Bulk liquid transfer, petrochemical blending |

Need a reliable seal for aggressive chemicals or high-purity systems?

KINTEK specializes in manufacturing high-performance PTFE components, including custom TFE encapsulated gaskets. We serve the semiconductor, medical, laboratory, and industrial sectors, providing precision seals from prototypes to high-volume orders.

Contact our experts today to discuss your specific application and ensure superior sealing performance.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Custom PTFE Square Trays for Industrial and Laboratory Use

People Also Ask

- What is the advantage of PTFE's self-lubricating properties in shaft seals? Achieve Reliable, Maintenance-Free Performance

- What makes PTFE-lined diaphragm valves suitable for wastewater treatment? Ensure Reliability and Cost Savings

- What advantage does the low friction property of PTFE oil seals provide? Extend Equipment Life & Save Energy

- How do different grades of Teflon (PTFE) affect machining? A Guide to Material Selection and Tooling

- What industries benefit from using PTFE plugs? Solve Extreme Sealing Challenges

- How are control valves customized for different processes? Tailor Performance for Your Application

- What are the key advantages of PTFE slide bearings? Achieve Maintenance-Free, High-Load Movement

- What industries extensively use PTFE membrane? The Critical Material for Safety & Purity