The primary advantages of PTFE slide bearings are their extremely low coefficient of friction, inherent self-lubricating properties, and maintenance-free operational life. This unique combination makes them a highly reliable and cost-effective solution for managing slow, high-load movements in large structures and heavy machinery by eliminating the need for external lubrication and resisting environmental degradation.

The core value of a PTFE slide bearing isn't just its slick surface; it's the long-term operational reliability it provides. These components are engineered to be installed and then trusted to perform for decades without intervention, making them a strategic choice for critical, inaccessible, or cost-sensitive applications.

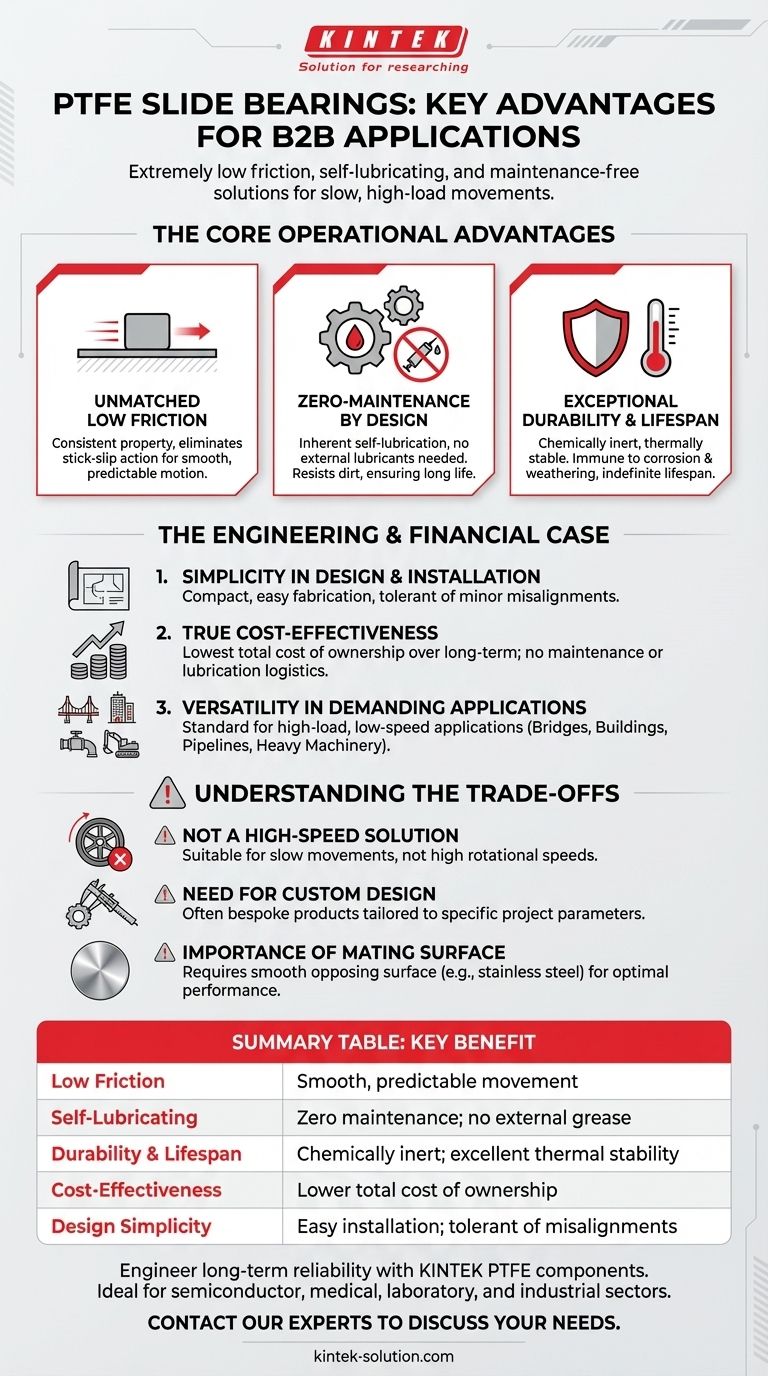

The Core Operational Advantages

To understand why PTFE bearings are specified for critical projects like bridges and large buildings, we must look beyond the surface features to their fundamental operational benefits.

Unmatched Low Friction

Polytetrafluoroethylene (PTFE) possesses one of the lowest coefficients of friction of any solid material. This property is consistent under a wide range of loads, temperatures, and speeds.

This eliminates stick-slip action, which is the jerky start-stop movement common in other bearing types. The result is smooth, predictable motion, which is crucial for accommodating gradual thermal expansion or seismic shifts in a structure.

Zero-Maintenance by Design

The molecular structure of PTFE provides inherent self-lubrication. As the bearing moves, a thin film of PTFE is transferred to the mating surface, creating a stable, low-friction interface.

This quality entirely removes the need for external lubricants like grease or oil. Consequently, the bearing does not attract and retain dirt, a common cause of abrasion and failure in traditional lubricated systems, ensuring a long and predictable service life.

Exceptional Durability and Lifespan

PTFE is chemically inert, meaning it is virtually immune to corrosion and degradation from chemicals or weathering. This makes it ideal for outdoor and harsh industrial environments.

Furthermore, it exhibits excellent thermal stability, performing reliably across a wide temperature range without becoming brittle or losing structural integrity. This resilience means the bearing has a nearly indefinite lifespan with no risk of fatigue failure.

The Engineering and Financial Case

The technical properties of PTFE bearings translate directly into significant engineering and financial benefits over the lifecycle of a project.

Simplicity in Design and Installation

PTFE slide bearings are mechanically simple components, which makes them easy to fabricate and install. Their compact design can reduce the complexity and footprint of the overall structural assembly.

This simplicity also allows them to be tolerant of minor misalignments, which can be difficult to avoid in large-scale construction, thereby simplifying the engineering process.

True Cost-Effectiveness

While some PTFE bearings are custom-engineered for specific projects, their true cost-effectiveness is realized over the long term.

With no maintenance requirements, no need for lubrication logistics, and an extremely long operational life, the total cost of ownership is significantly lower than that of mechanical bearing systems that require regular inspection and service.

Versatility in Demanding Applications

These bearings are essential in applications that involve high loads but low speeds. They are a standard solution in:

- Bridges and Viaducts: To accommodate thermal expansion and contraction.

- Long-Span Buildings: To manage movement between structural elements.

- Pipelines: To allow for thermal and seismic movement.

- Heavy Machinery: To provide smooth, high-load pivot points.

Understanding the Trade-offs and Considerations

While highly effective, PTFE slide bearings are not a universal solution. Understanding their limitations is key to using them correctly.

Not a High-Speed Solution

The primary strength of PTFE bearings is in managing slow movements, such as the gradual expansion of a bridge deck. They are not suitable for high-speed rotational applications, where heat buildup and wear would become significant issues.

The Need for Custom Design

Because they are often used in unique, critical structures, PTFE bearings are frequently bespoke products rather than off-the-shelf commodities. Each project's specific load, movement, and environmental parameters must be understood to engineer an effective solution.

Importance of the Mating Surface

The performance of a PTFE bearing is highly dependent on the opposing surface, which is typically stainless steel. This surface must be polished to a very smooth finish to ensure the lowest possible friction and prevent abrasion of the softer PTFE material.

Making the Right Choice for Your Application

Selecting the right bearing is about matching the component's strengths to your project's most critical goal.

- If your primary focus is minimizing long-term operational costs: The maintenance-free, self-lubricating nature of PTFE bearings offers the lowest total cost of ownership.

- If your primary focus is accommodating slow, heavy structural movement: The consistently low coefficient of friction and high load capacity make them the most reliable choice.

- If your primary focus is durability in harsh environments: The chemical inertness and wide temperature tolerance of PTFE ensure performance where other materials would fail.

Ultimately, choosing a PTFE slide bearing is a strategic decision to engineer long-term reliability directly into a structure.

Summary Table:

| Advantage | Key Benefit |

|---|---|

| Low Friction | Smooth, predictable movement; eliminates stick-slip |

| Self-Lubricating | Zero maintenance; no external grease or oil required |

| Durability & Lifespan | Chemically inert; excellent thermal stability |

| Cost-Effectiveness | Lower total cost of ownership due to no maintenance |

| Design Simplicity | Easy installation; tolerant of minor misalignments |

Engineer long-term reliability into your project with KINTEK PTFE components.

Our precision-manufactured PTFE slide bearings are designed for the demanding environments of the semiconductor, medical, laboratory, and industrial sectors. Whether you need a custom prototype or a high-volume order, KINTEK delivers the durability and maintenance-free performance your critical applications require.

Contact our experts today to discuss your specific load, movement, and environmental needs.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Customizable PTFE Rods for Advanced Industrial Applications

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

People Also Ask

- How does PTFE contribute to low friction and wear resistance? Achieve Superior Performance with Advanced Materials

- What are the key advantages of PTFE? Unmatched Performance for Extreme Environments

- What are the future considerations for machining Teflon? Mastering Material Challenges with Smart Tech

- What tips can improve Teflon machining results? Master Sharp Tools, Heat Control, and Rigid Support

- Why is CNC machining preferred for Teflon parts over other methods? Unlock Precision & Complex Designs