At its core, a control valve is not a single product but a custom-assembled system. Each valve is engineered from a selection of core components—body, trim, and actuator—to precisely match the unique demands of a specific process. Because they are so highly specialized for factors like fluid type, pressure, temperature, and desired control behavior, control valves are almost never interchangeable between different applications.

The customization of a control valve is not about adding features for their own sake. It is a critical engineering process to ensure the valve can survive its environment, provide stable control, and operate safely within a complex industrial system.

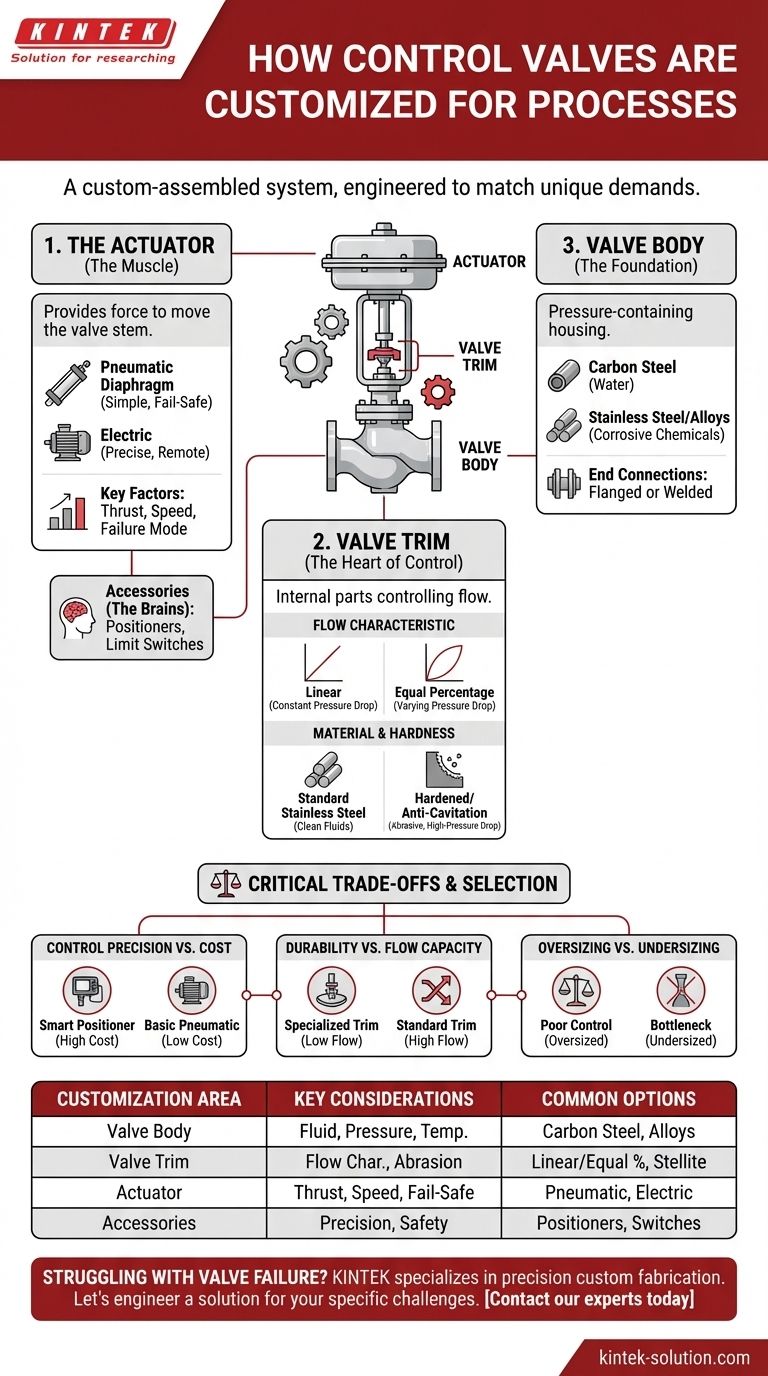

The Anatomy of Customization: Key Valve Components

To understand how a valve is tailored, we must look at its three primary component groups: the body, the internal trim, and the actuator that drives it.

Valve Body: The Foundation

The valve body is the pressure-containing housing. Its customization begins with material selection, which is dictated entirely by the process fluid and operating conditions.

A simple water application might use carbon steel, while a corrosive chemical requires stainless steel or more exotic alloys like Hastelloy or Monel. End connections are also specified, such as flanged for easy maintenance or welded for high-integrity, no-leak service.

Valve Trim: The Heart of Control

The trim is the set of internal parts that directly control the fluid flow. This is the most critical area of customization for performance. It consists of the plug (or disk), the seat, and the stem.

Trim customization focuses on two areas:

- Flow Characteristic: The shape of the valve plug determines how the flow rate changes as the valve opens. A linear characteristic is used when the valve's pressure drop remains constant, while an equal percentage characteristic is better for systems where pressure drop varies, providing more stable control.

- Material and Hardness: For clean fluids, standard stainless steel is sufficient. For abrasive slurries, high-pressure-drop liquids that can cause cavitation, or high-velocity gases that cause erosion, the trim must be made from hardened materials like Stellite or feature specialized anti-cavitation designs.

The Actuator: The Muscle

The actuator provides the force needed to move the valve stem and overcome the forces from the process fluid. The choice of actuator depends on the required thrust, speed, and failure mode.

The most common type is the pneumatic diaphragm actuator, valued for its simplicity and ability to provide a "fail-safe" position (either fail-open or fail-close on loss of air supply). Electric actuators are chosen for remote locations without compressed air or for applications requiring very precise positioning.

Positioners and Accessories: The Brains

A modern control valve rarely works alone. A positioner is almost always attached to the actuator. It acts as a sophisticated controller, translating the electronic control signal (e.g., 4-20mA) into the precise air pressure or motor position needed to move the valve to the exact desired point, overcoming friction and other process disturbances.

Other accessories like limit switches can be added to send a signal confirming the valve is fully open or closed, while solenoid valves can be used to override the control signal for an emergency shutdown.

Understanding the Critical Trade-offs

Specifying a control valve is a balancing act. Every decision involves a trade-off between performance, longevity, and cost.

Control Precision vs. Cost

A highly responsive electric actuator paired with a smart digital positioner offers superior control accuracy. However, this setup is significantly more expensive than a basic pneumatic actuator and may be overkill for a simple process like tank level control.

Durability vs. Flow Capacity

For severe service applications with flashing or cavitation, specialized trim designs are required. These designs use complex, tortuous paths to manage the fluid's energy. While this protects the valve from damage, it often makes the valve more restrictive, reducing its overall flow capacity (Cv).

Oversizing vs. Undersizing

One of the most common and costly mistakes is improper sizing. An undersized valve cannot pass the required flow, bottlenecking the entire process. A severely oversized valve is just as problematic; it will operate too close to its seat, resulting in poor control stability and rapid erosion of the trim components.

Selecting the Right Valve for Your Process

The ideal valve is one that meets the technical requirements without being over-engineered. Your final specification should be driven by the primary challenge of the application.

- If your primary focus is general-purpose control: A standard globe valve with a pneumatic actuator and a smart positioner is often the most reliable and cost-effective choice.

- If your primary focus is combating severe service: Prioritize the trim material (e.g., Stellite) and design (e.g., anti-cavitation) to ensure valve longevity.

- If your primary focus is managing corrosive fluids: The selection of body and trim materials is the most important decision you will make.

- If your primary focus is precise and rapid response: An electric actuator may be necessary, as it can offer faster and more repeatable positioning than a pneumatic alternative.

Ultimately, a well-specified control valve is the result of a deep understanding of the process it is meant to serve.

Summary Table:

| Customization Area | Key Considerations | Common Options |

|---|---|---|

| Valve Body | Process fluid, pressure, temperature | Carbon steel, stainless steel, Hastelloy, Monel |

| Valve Trim | Flow characteristic, abrasion, cavitation | Linear/Equal % plug, Stellite-hardened parts |

| Actuator | Required thrust, speed, fail-safe mode | Pneumatic diaphragm, Electric |

| Accessories | Control precision, safety, monitoring | Positioners, limit switches, solenoid valves |

Struggling with valve failure or poor process control? Your application is unique, and your components should be too.

At KINTEK, we specialize in precision manufacturing and custom fabrication of critical components like PTFE seals and liners for demanding industries. Just as a control valve must be tailored to its process, your components must be engineered to withstand specific chemical, thermal, and pressure environments.

We partner with semiconductor, medical, laboratory, and industrial clients to deliver solutions from prototypes to high-volume orders, ensuring reliability and performance.

Let's engineer a solution for your specific challenges. Contact our experts today to discuss your requirements.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Teflon Parts Manufacturer Adjustable Height Flower Basket

- Custom PTFE Volumetric Flasks for Advanced Scientific and Industrial Use

- Customizable PTFE Seals Filter Holders for Versatile Applications

People Also Ask

- What is the working temperature range of PTFE? Master Extreme Heat and Cryogenic Applications

- What are the unique properties of PTFE? Unlock Unmatched Performance in Demanding Applications

- What is PTFE commonly known as and what are its unique properties? Unlock Unmatched Chemical & Thermal Resistance

- What are some common applications of machined PTFE? Leverage its Unique Properties for Demanding Applications

- What are the material advantages of machining Teflon? Unlock Unmatched Chemical & Thermal Resistance