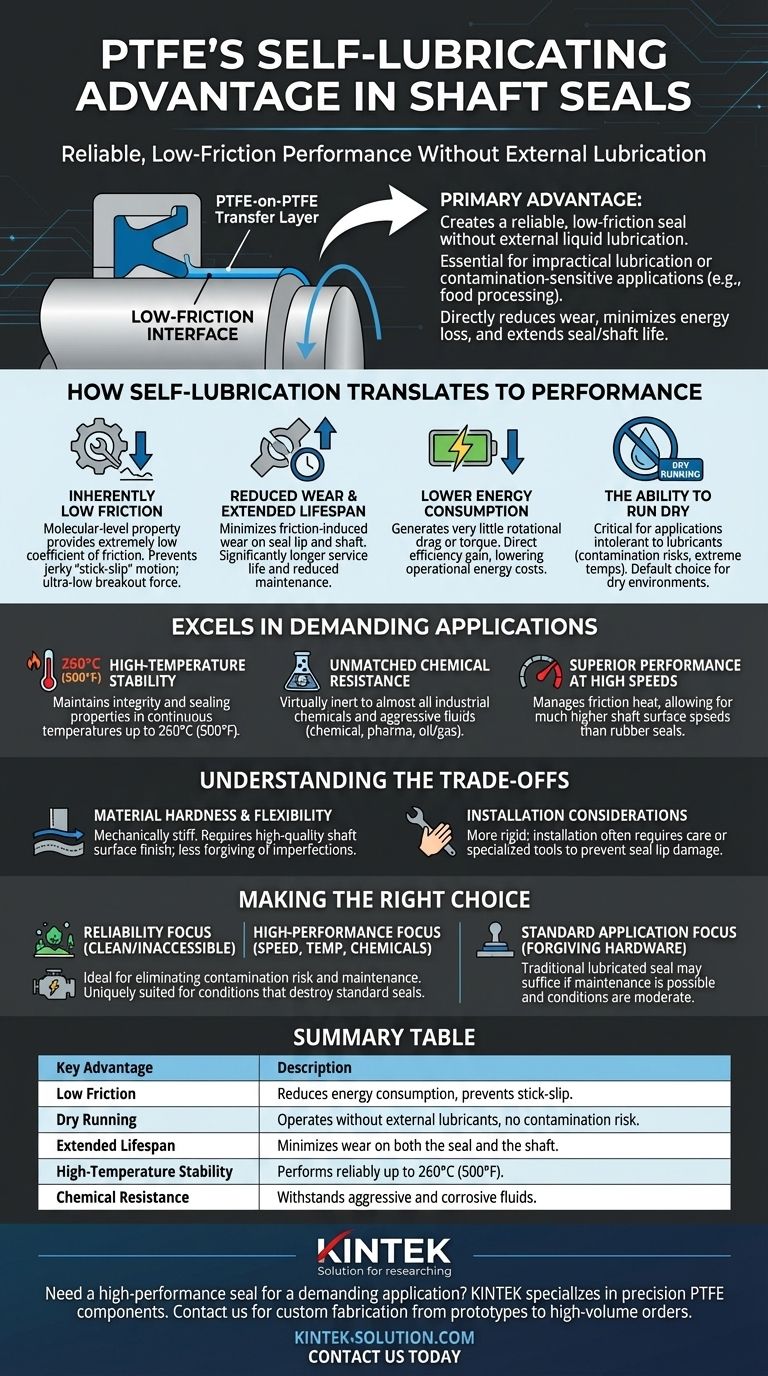

The primary advantage of PTFE's self-lubricating property is its ability to create a reliable, low-friction seal without the need for external liquid lubrication. This capability is critical in applications where adding lubricants is impractical or where contamination is unacceptable, such as in food processing. This inherent characteristic directly reduces wear, minimizes energy loss, and significantly extends the operational life of both the seal and the shaft.

The self-lubricating nature of PTFE isn't just about convenience; it's a fundamental performance driver. By creating an inherently low-friction sealing surface, it enables reliable operation in extreme conditions where traditional lubricated seals would prematurely fail.

How Self-Lubrication Translates to Performance

The term "self-lubricating" describes a material's intrinsic ability to minimize friction. In PTFE, this translates into several distinct operational advantages that go far beyond simply eliminating grease.

Inherently Low Friction

PTFE has one of the lowest coefficients of friction of any solid material. This is a molecular-level property.

During initial operation, a microscopic layer of PTFE transfers from the seal lip to the shaft surface, creating a PTFE-on-PTFE interface. This dynamic results in extremely low "breakout friction" (the force needed to start movement) and prevents the jerky "stick-slip" motion common with other materials.

Reduced Wear and Extended Lifespan

Friction is the primary cause of wear in any sealing system. Because PTFE minimizes this force, it dramatically reduces wear on both the seal lip and the expensive shaft it runs against.

This leads to a significantly longer service life and reduced maintenance intervals, justifying its use in critical or hard-to-service machinery.

Lower Energy Consumption

High friction requires more energy to turn a shaft. PTFE seals generate very little rotational drag or torque.

This efficiency gain translates directly into lower energy consumption, which is a significant factor in continuously operating industrial equipment.

The Ability to Run Dry

The most direct benefit of self-lubrication is the capacity for dry running.

Many sealing applications cannot tolerate lubricants due to contamination risks (e.g., food, medical, aerospace) or extreme temperatures that would break down oil or grease. PTFE is the default choice in these scenarios.

Why PTFE Excels in Demanding Applications

Self-lubrication is a cornerstone property, but its true value emerges when combined with PTFE's other unique characteristics. This synergy makes it the preferred material for the most challenging sealing environments.

High-Temperature Stability

PTFE seals maintain their integrity and sealing properties in continuous temperatures up to 260°C (500°F).

This allows them to perform reliably in high-heat applications like engines, transmissions, and industrial machinery where conventional rubber seals would quickly degrade.

Unmatched Chemical Resistance

PTFE is virtually inert to almost all industrial chemicals and aggressive fluids.

This makes it the only viable option for sealing applications in the chemical processing, pharmaceutical, and oil and gas industries, where seals are exposed to corrosive materials.

Superior Performance at High Speeds

The combination of low friction and high-temperature tolerance allows PTFE seals to handle much higher shaft surface speeds than rubber seals.

Excessive speed generates heat from friction, which can destroy an elastomer seal. PTFE's ability to manage this heat allows it to maintain a stable seal under high-RPM conditions.

Understanding the Trade-offs

While powerful, PTFE is not a universal solution. Its physical properties present certain trade-offs that are critical to understand for proper application.

Material Hardness and Flexibility

PTFE is a mechanically stiff material compared to highly flexible elastomers like rubber.

This means it is less forgiving of shaft imperfections, surface finish irregularities, or significant shaft runout (wobble). A high-quality shaft surface is essential for optimal PTFE seal performance.

Installation Considerations

Due to its rigidity, a PTFE seal lip cannot be stretched over a shaft as easily as a rubber seal.

Installation often requires more care, and sometimes specialized tools are needed to prevent damage to the precision-engineered seal lip during assembly.

Making the Right Choice for Your Application

To select the right seal, match the material's core strengths to your primary operational challenge.

- If your primary focus is reliability in a clean or inaccessible environment: PTFE is the ideal choice, as its self-lubrication eliminates both contamination risk and the need for periodic maintenance.

- If your primary focus is high-performance (high speed, temperature, or aggressive chemicals): PTFE's combined thermal stability, chemical inertness, and low-friction properties make it uniquely suited for conditions that would destroy standard seals.

- If your primary focus is a standard application with a forgiving hardware setup: A traditional lubricated elastomer seal may be sufficient, provided that periodic maintenance is possible and the operating conditions are moderate.

Ultimately, choosing a PTFE seal is an engineering decision that prioritizes long-term operational stability and efficiency in demanding environments.

Summary Table:

| Key Advantage | Description |

|---|---|

| Low Friction | Reduces energy consumption and prevents stick-slip motion. |

| Dry Running | Operates without external lubricants, eliminating contamination risk. |

| Extended Lifespan | Minimizes wear on both the seal and the shaft. |

| High-Temperature Stability | Performs reliably in continuous temperatures up to 260°C (500°F). |

| Chemical Resistance | Withstands exposure to aggressive and corrosive fluids. |

Need a high-performance seal for a demanding application?

KINTEK specializes in manufacturing precision PTFE components, including seals, liners, and labware, for industries where reliability is non-negotiable. Our custom fabrication services, from prototypes to high-volume orders, ensure you get a sealing solution that delivers long-term operational stability and efficiency.

Contact us today to discuss your specific requirements and see how our expertise can benefit your project.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Teflon Balls for Advanced Industrial Applications

People Also Ask

- What modifications are available for PTFE plastics? Enhance Performance for Demanding Applications

- What is the difference between Teflon and generic PTFE? A Guide to High-Performance Fluoropolymers

- How do the low friction properties of Teflon plastic sheets enhance industrial performance? Reduce Wear & Boost Efficiency

- What are the key reasons to choose PTFE washers? Unmatched Performance in Demanding Environments

- Can PTFE machined parts be customized according to specific requirements? Achieve Precision for Demanding Applications

- What temperature range can PTFE balls typically withstand? From -200°C to +260°C with Key Limitations

- What are the properties of PTFE gaskets? Unlock Superior Sealing for Demanding Applications

- Why is PTFE used for thermal and electrical insulation? Unmatched Stability in Extreme Conditions