At its core, Polytetrafluoroethylene (PTFE) membrane is a critical material in nearly every advanced industry. Its use is widespread, spanning chemical processing, medical and pharmaceutical manufacturing, food and beverage production, electronics and semiconductors, and aerospace and automotive engineering. This broad adoption is not accidental; it is a direct result of PTFE's unique and powerful combination of material properties.

The widespread use of PTFE isn't about the material itself, but about what it enables: uncompromised safety, purity, and reliability in the most demanding operational environments. Industries don't choose PTFE; they choose the operational certainty it guarantees.

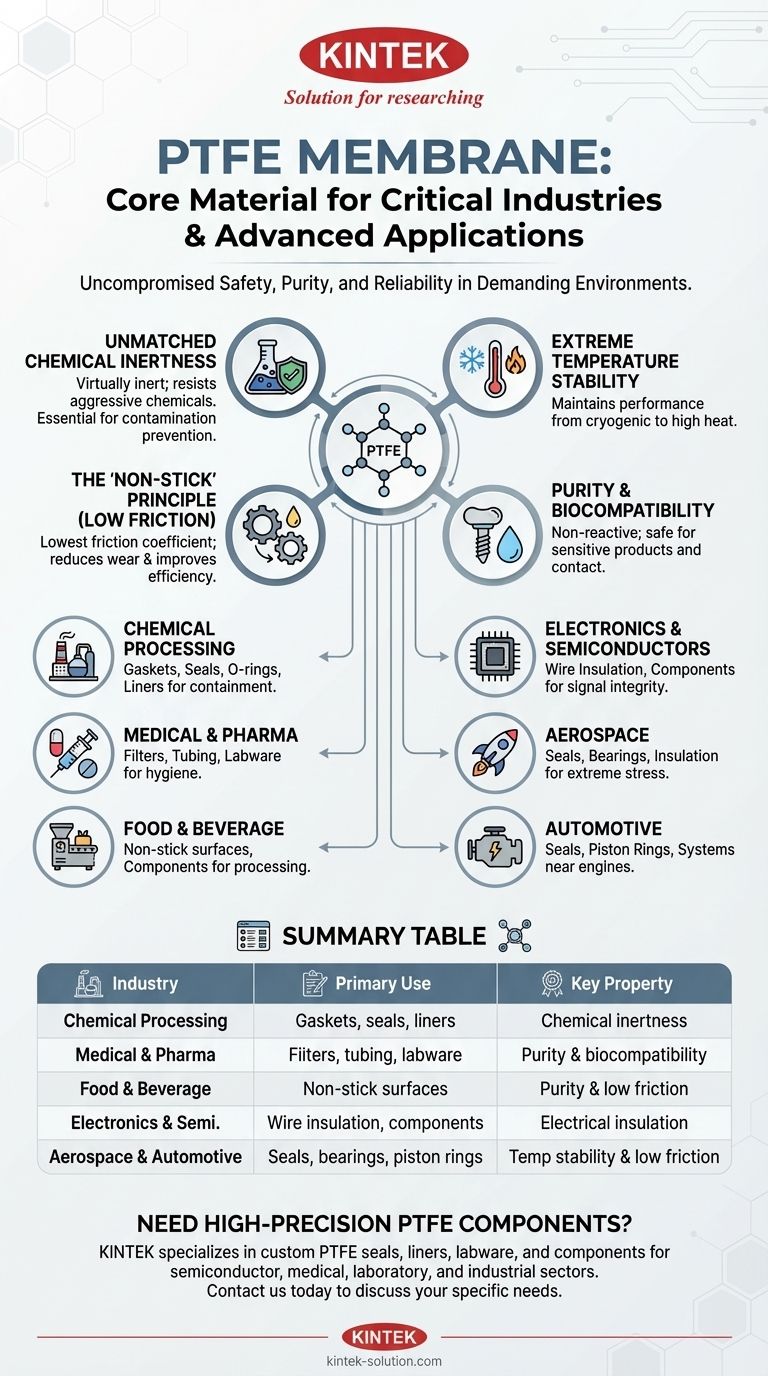

Why PTFE is a Go-To Material for Critical Applications

The versatility of PTFE stems from a few core characteristics that make it an ideal solution for problems other materials cannot solve. Understanding these properties explains its presence in such diverse fields.

Unmatched Chemical Inertness

PTFE is virtually inert, meaning it does not react with the vast majority of industrial chemicals, acids, and bases. This makes it an essential material for equipment that handles corrosive substances.

This property is why it's a staple in chemical processing plants, pharmaceutical manufacturing, and laboratory applications where preventing contamination and equipment degradation is paramount.

Extreme Temperature Stability

The material maintains its integrity and performance across a huge range of temperatures, from cryogenic lows to high-heat applications.

This resilience is critical in power plants for handling high-pressure steam, in aerospace components exposed to atmospheric temperature swings, and in automotive systems near engines.

The 'Non-Stick' Principle (Low Friction)

PTFE has one of the lowest coefficients of friction of any solid material, which gives it its famous non-stick quality.

This is leveraged in mechanical applications like gears, seals, and bearing pads to reduce wear and improve efficiency. It also ensures that products in the food and beverage industry move through processing equipment without sticking or leaving residue.

Purity and Biocompatibility

Because PTFE is inert and stable, it does not leach chemicals into its environment. This makes it safe for direct contact with sensitive products.

This biocompatibility is non-negotiable in the medical field for surgical tools and implants, and it ensures product purity in food, beverage, and semiconductor manufacturing, where even trace contamination can be catastrophic.

A Look at Specific Applications Across Industries

The theoretical properties of PTFE translate into tangible, critical components used every day.

In Chemical and Petrochemical Processing

Here, the primary concern is safely containing and transporting highly corrosive materials. PTFE is used to manufacture durable gaskets, seals, O-rings, and expansion joints that prevent dangerous leaks.

In Medical, Pharmaceutical, and Food Production

In these fields, hygiene and purity are the main drivers. PTFE's non-reactive and non-stick surface is used for filters, tubing for fluid transport, and components in processing equipment that meet strict safety standards.

In Electronics and Semiconductor Manufacturing

PTFE is an exceptional electrical insulator. This property is vital for manufacturing high-performance wire and cable insulation, especially in consumer electronics and aerospace applications where signal integrity is key.

In Aerospace and Automotive Engineering

These industries demand components that perform reliably under extreme stress, friction, and temperature. PTFE is used for seals, bearings, and piston rings that require durability and low-friction operation to ensure safety and efficiency.

Understanding the Trade-offs

While incredibly useful, PTFE is not a universal solution. Being an effective technical advisor means acknowledging its limitations.

Mechanical Properties

Compared to many engineering plastics, PTFE is relatively soft and can be prone to "creep"—deforming slowly over time when under a constant load. This must be accounted for in structural designs.

Processing Challenges

PTFE cannot be processed using conventional methods like injection molding. It requires specialized techniques like sintering, which can increase manufacturing complexity and cost.

Relative Cost

Its unique properties and specialized manufacturing process mean that PTFE is generally more expensive than commodity plastics. The choice to use it is a deliberate investment in performance and safety where other materials would fail.

Making the Right Choice for Your Goal

The decision to use PTFE should be driven by the specific demands of your application.

- If your primary focus is chemical resistance and purity: PTFE is the industry standard for handling aggressive chemicals or maintaining sterile environments in pharma and food processing.

- If your primary focus is low-friction and high-temperature performance: It is a leading choice for demanding mechanical applications like bearings and seals in aerospace and automotive systems.

- If your primary focus is electrical insulation: PTFE provides exceptional dielectric properties, making it essential for high-performance wiring and critical electronic components.

Ultimately, PTFE's versatility makes it a foundational problem-solving material for engineering's most demanding challenges.

Summary Table:

| Industry | Primary Use of PTFE Membrane | Key Property Utilized |

|---|---|---|

| Chemical Processing | Gaskets, seals, liners | Chemical inertness |

| Medical & Pharma | Filters, tubing, labware | Purity & biocompatibility |

| Food & Beverage | Non-stick surfaces, filters | Purity & low friction |

| Electronics & Semiconductors | Wire insulation, components | Electrical insulation |

| Aerospace & Automotive | Seals, bearings, piston rings | Temperature stability & low friction |

Need high-precision PTFE components for your critical application?

KINTEK specializes in manufacturing custom PTFE seals, liners, labware, and other components for the semiconductor, medical, laboratory, and industrial sectors. We ensure uncompromised safety, purity, and reliability in the most demanding environments through precision production and custom fabrication—from prototypes to high-volume orders.

Contact us today to discuss how our PTFE solutions can meet your specific needs.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Customizable PTFE Seals Filter Holders for Versatile Applications

- Custom PTFE Square Trays for Industrial and Laboratory Use

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

People Also Ask

- How do the costs of Teflon encapsulated O-rings compare to other sealing solutions? A Guide to Total Cost of Ownership

- What are the best practices for drilling and tapping PTFE? Achieve Clean, Precise Machining

- Why is PTFE used in anti-corrosion applications? Unmatched Chemical Resistance for Harsh Environments

- How do Teflon bushes perform in chemically harsh environments? Unmatched Chemical Resistance for Critical Applications

- What are the key properties of Teflon (PTFE) that make it suitable for machining? Balancing Performance with Machining Challenges

- What are the characteristics of graphite PTFE gland packings? High-Performance Sealing for Demanding Applications

- Are fibrous fillers better than particulate fillers in PTFE? Optimize Your PTFE Component Performance

- What are the typical characteristics and applications of O-ring materials? Find the Right Seal for Extreme Environments