Successfully machining PTFE requires a strategy that prioritizes finesse over force. The best practice is to use extremely sharp tools at high spindle speeds but with a very low feed rate, a combination that shears the material cleanly before its two most challenging properties—softness and poor heat dissipation—can compromise the result.

The core challenge in working with PTFE is not cutting it, but rather cutting it precisely without causing it to deform, melt, or tear. Your success depends entirely on managing heat buildup and tool pressure.

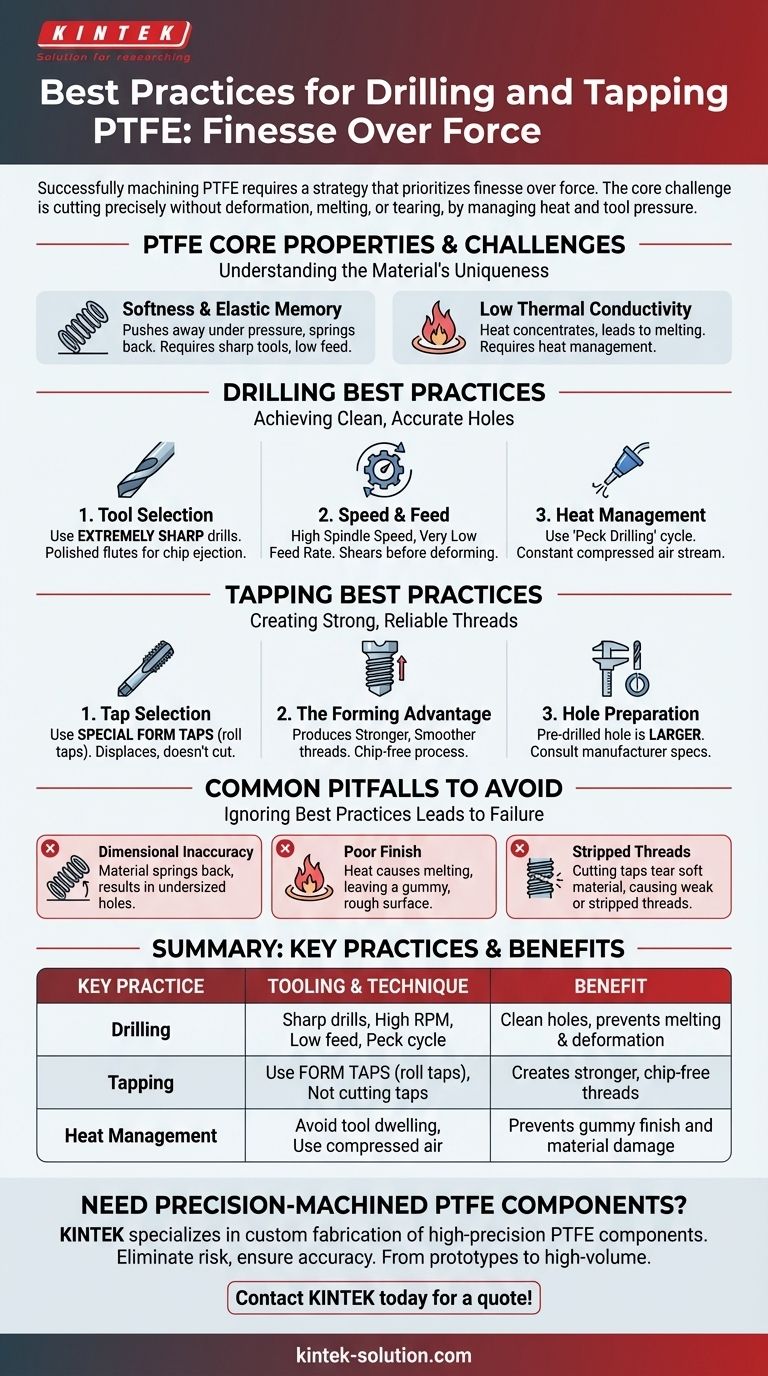

Understanding the Core Challenge: PTFE's Properties

To machine PTFE effectively, you must first understand the material itself. Its unique characteristics are what make standard machining practices ineffective.

Softness and Elastic Memory

PTFE is an exceptionally soft and pliable material. Under the pressure of a dull tool or an aggressive feed rate, it will push away, stretch, and deform rather than forming a clean chip. It also has an elastic memory, meaning it may spring back after the tool passes, resulting in undersized holes.

Low Thermal Conductivity

Unlike metals, PTFE does not conduct heat away from the cutting tool. This causes heat to concentrate at the point of contact, which can quickly lead to melting, gummy chip formation, and a poor surface finish.

Best Practices for Drilling PTFE

Achieving a clean, dimensionally accurate hole in PTFE requires careful attention to tooling and technique.

Tool Selection is Critical

Your primary tool must be exceptionally sharp. Drills designed specifically for plastics, which often have a more acute point angle and highly polished flutes, are ideal. A sharp edge cleanly shears the material, while polished flutes help eject the gummy chips efficiently.

High Speeds, Low Feeds

Use a high spindle speed (RPM) to ensure the cutting edge is moving fast enough to shear the material before it can deform. Combine this with a very low feed rate. Pushing the drill into the material too quickly will cause it to tear and deform rather than cut.

Manage Heat Buildup

Never allow the tool to dwell in one place. Using a "peck drilling" cycle—where the drill advances slightly and then retracts to clear chips—is highly effective. This action breaks the chip and allows both the tool and the workpiece a moment to cool. A constant stream of compressed air can also help clear chips and provide some cooling.

Best Practices for Tapping PTFE

Creating threads in PTFE presents a similar set of challenges. The softness of the material makes it easy to strip or create weak threads if the wrong approach is used.

Use Form Taps, Not Cutting Taps

The most significant best practice for tapping PTFE is to use special form taps (also known as cold forming or roll taps). These tools do not cut material away. Instead, they displace and compress the PTFE to form the thread profile.

The Advantage of Forming

This method produces a much stronger, smoother, and more precise thread. Because no chips are created, the process is cleaner and avoids the risk of chips binding in the hole. This directly addresses the goal of "threading without cutting."

Hole Preparation

When using a form tap, the pre-drilled hole size is critical and will be larger than the size required for a standard cutting tap. Always consult the tap manufacturer's specifications to drill the correct size hole to ensure proper material flow.

Understanding the Trade-offs and Pitfalls

Ignoring these best practices can lead to several common failures that are frustrating and costly.

The Risk of Dimensional Inaccuracy

Using dull tools or excessive feed pressure will cause the PTFE to stretch around the drill bit. When the tool is removed, the material will spring back, resulting in a hole that is significantly smaller than the drill bit used to create it.

The Problem of a Poor Finish

Heat is the enemy of a good surface finish in PTFE. If your spindle speed is too low or your tool is not sharp enough, friction will melt the material, leaving a gummy, rough, and unacceptable surface inside the hole or on the threads.

The Danger of Stripped Threads

Attempting to use a standard cutting tap, especially an aggressive one, is the most common cause of failed threads. The tap's cutting edges will tend to tear and pull the soft material, resulting in threads that are weak, poorly formed, or completely stripped out.

Making the Right Choice for Your Goal

Adapt your technique based on your most critical outcome.

- If your primary focus is dimensional accuracy: Prioritize extremely sharp tooling and a peck drilling cycle with very low feed rates to eliminate heat and material deformation.

- If your primary focus is strong, reliable threads: The definitive solution is to use a form tap instead of a cutting tap, ensuring your pre-drilled hole is sized correctly for forming.

- If you are experiencing poor surface finish: The immediate factors to address are increasing your spindle speed and verifying your cutting tools are as sharp as possible.

By treating PTFE with the unique approach it requires, you can consistently produce clean, precise, and reliable results.

Summary Table:

| Key Practice | Tooling & Technique | Benefit |

|---|---|---|

| Drilling | Sharp drills, high RPM, low feed rate, peck cycle | Clean holes, prevents melting & deformation |

| Tapping | Use form taps (roll taps), not cutting taps | Creates stronger, chip-free threads |

| Heat Management | Avoid tool dwelling, use compressed air | Prevents gummy finish and material damage |

Need Precision-Machined PTFE Components?

Machining PTFE in-house requires specialized skill and tooling. Why risk material waste and production delays? KINTEK specializes in the custom fabrication of high-precision PTFE components—including seals, liners, labware, and complex parts with drilled and tapped features.

We serve the semiconductor, medical, laboratory, and industrial sectors, delivering the dimensional accuracy and superior surface finish your applications demand. From prototypes to high-volume orders, our expertise ensures your PTFE parts are made right the first time.

Let us handle the precision machining for you. Contact KINTEB today for a quote!

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Customizable PTFE Rods for Advanced Industrial Applications

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

- Custom PTFE Teflon Balls for Advanced Industrial Applications

People Also Ask

- What is PTFE and what makes it suitable for gaskets? The Ultimate Guide to High-Performance Sealing

- What are the application advantages of PEEK backup rings? Achieve Unmatched Sealing Integrity in Extreme Conditions

- What role do PTFE rotary shaft lip seals play in the oil and gas industry? Ensure Reliability in Extreme Conditions

- What is the coefficient of friction for PTFE O-Rings and why is it beneficial? Achieve Smooth, Low-Friction Performance

- What are symptoms of temperature-induced PTFE lip seal failure? Identify the Cause of Your Leaks

- How does the PTFE lining extend the valve's service life? The Ultimate Shield Against Corrosion and Wear

- What are the key properties of Teflon bushings? Achieve Superior Performance in Demanding Industrial Environments

- What are the core material options for PTFE encapsulated O-rings? Choose Viton® or Silicone for Your Sealing Needs