In short, Polytetrafluoroethylene (PTFE) is a high-performance synthetic fluoropolymer, best known by the brand name Teflon. Its unique molecular structure, composed of strong carbon-fluorine bonds, gives it an extraordinary combination of chemical inertness, thermal stability, and low friction, making it one of the most reliable and versatile materials for industrial gaskets.

The core reason PTFE excels in sealing applications is its unparalleled ability to resist nearly all industrial chemicals and withstand high temperatures while providing a durable, non-stick seal that won't degrade under harsh conditions.

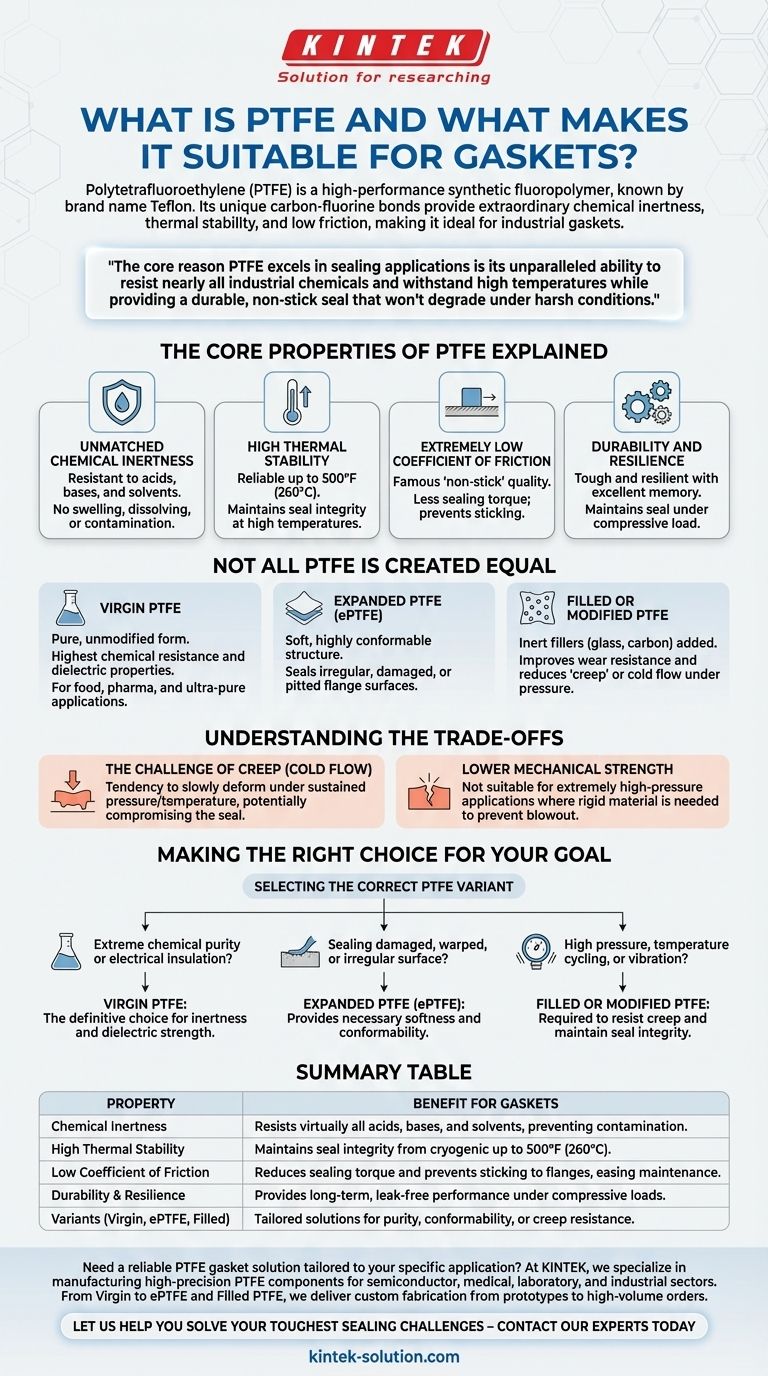

The Core Properties of PTFE Explained

To understand why PTFE is a default choice for demanding environments, we must look at its fundamental characteristics. Each property solves a specific challenge faced by engineers and maintenance professionals.

Unmatched Chemical Inertness

PTFE is a fluoropolymer, meaning its molecular backbone is protected by a tight sheath of fluorine atoms. This carbon-fluorine bond is exceptionally strong and stable.

This structure makes PTFE gaskets resistant to virtually all chemicals, including aggressive acids, bases, and solvents. This inertness ensures the gasket will not swell, dissolve, or contaminate the process media.

High Thermal Stability

PTFE gaskets perform reliably across a wide temperature range, typically up to 500°F (260°C).

This stability prevents the material from becoming brittle at low temperatures or degrading at high temperatures, ensuring a consistent seal integrity even when system conditions fluctuate.

Extremely Low Coefficient of Friction

PTFE has one of the lowest coefficients of friction of any solid material, giving it its famous "non-stick" quality.

For a gasket, this means less torque is required to create a seal, and the gasket is less likely to stick to flange surfaces during removal. This simplifies maintenance and reduces the risk of damaging equipment.

Durability and Resilience

Despite its slick surface, PTFE is a tough and resilient material. It resists wear and has excellent memory, allowing it to maintain a seal under the compressive load of a flange. This ensures long-term, leak-free performance.

Not All PTFE is Created Equal

While all PTFE shares these core properties, different forms have been developed to enhance performance for specific applications. Understanding these types is key to a successful seal.

Virgin PTFE

This is the pure, unmodified form of PTFE. It offers the highest chemical resistance and best dielectric (electrical insulating) properties. It is the go-to choice for food, pharmaceutical, and ultra-pure chemical applications.

Expanded PTFE (ePTFE)

This form of PTFE is manufactured to have a soft, highly conformable structure. Expanded PTFE is excellent for sealing damaged, pitted, or otherwise irregular flange surfaces. It compresses easily into a thin, strong gasket under load.

Filled or Modified PTFE

To overcome some of the mechanical limitations of virgin PTFE, inert filler materials can be added. Common fillers include glass, carbon, or graphite. These agents can significantly improve the gasket's wear resistance and, most importantly, reduce its tendency to "creep" or cold flow under pressure.

Understanding the Trade-offs

No material is perfect, and being a trusted advisor means acknowledging a material's limitations. Understanding PTFE's primary trade-off is critical for proper application.

The Challenge of Creep (Cold Flow)

The primary weakness of virgin PTFE is its tendency to creep, also known as cold flow. Under sustained pressure and temperature, the material can slowly deform and flow out of the flange.

This loss of material can reduce the bolt load, compromising the integrity of the seal over time. This is precisely why filled PTFE grades were developed—to provide the chemical resistance of PTFE with improved mechanical stability.

Lower Mechanical Strength

Compared to metallic or some composite gaskets, PTFE is a relatively soft material. It is not suitable for extremely high-pressure applications where a stronger, more rigid material is required to prevent blowout.

Making the Right Choice for Your Goal

Selecting the correct PTFE variant is essential for achieving a reliable, long-lasting seal. Your decision should be guided by the specific demands of your operating environment.

- If your primary focus is extreme chemical purity or electrical insulation: Virgin PTFE is the definitive choice for its inertness and dielectric strength.

- If you are sealing a damaged, warped, or irregular surface: Expanded PTFE (ePTFE) provides the necessary softness and conformability to create an effective seal.

- If your application involves high pressure, temperature cycling, or vibration: A filled or modified PTFE is required to resist creep and maintain long-term seal integrity.

By understanding the distinct properties of PTFE and its variants, you can confidently select the precise material to solve your most challenging sealing problems.

Summary Table:

| Property | Benefit for Gaskets |

|---|---|

| Chemical Inertness | Resists virtually all acids, bases, and solvents, preventing contamination. |

| High Thermal Stability | Maintains seal integrity from cryogenic temperatures up to 500°F (260°C). |

| Low Coefficient of Friction | Reduces sealing torque and prevents sticking to flanges, easing maintenance. |

| Durability & Resilience | Provides long-term, leak-free performance under compressive loads. |

| Variants (Virgin, ePTFE, Filled) | Tailored solutions for purity, conformability, or creep resistance. |

Need a reliable PTFE gasket solution tailored to your specific application?

At KINTEK, we specialize in manufacturing high-precision PTFE components—including seals, gaskets, liners, and custom labware—for the semiconductor, medical, laboratory, and industrial sectors. Whether you require the chemical purity of Virgin PTFE, the conformability of Expanded PTFE (ePTFE) for irregular surfaces, or the enhanced creep resistance of Filled PTFE for high-pressure environments, we deliver custom fabrication from prototypes to high-volume orders.

Let us help you solve your toughest sealing challenges—contact our experts today for a consultation!

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Teflon Balls for Advanced Industrial Applications

People Also Ask

- What are the main advantages of using PTFE parts in industrial applications? Unlock Unmatched Chemical Resistance and Reliability

- What tips can improve Teflon machining results? Master Sharp Tools, Heat Control, and Rigid Support

- What are the key considerations when machining Teflon? Master Precision Machining for Soft Polymers

- What are the best practices for achieving tight tolerances in Teflon (PTFE) machining? Master Precision for Demanding Applications

- Why is CNC machining preferred for Teflon parts over other methods? Unlock Precision & Complex Designs