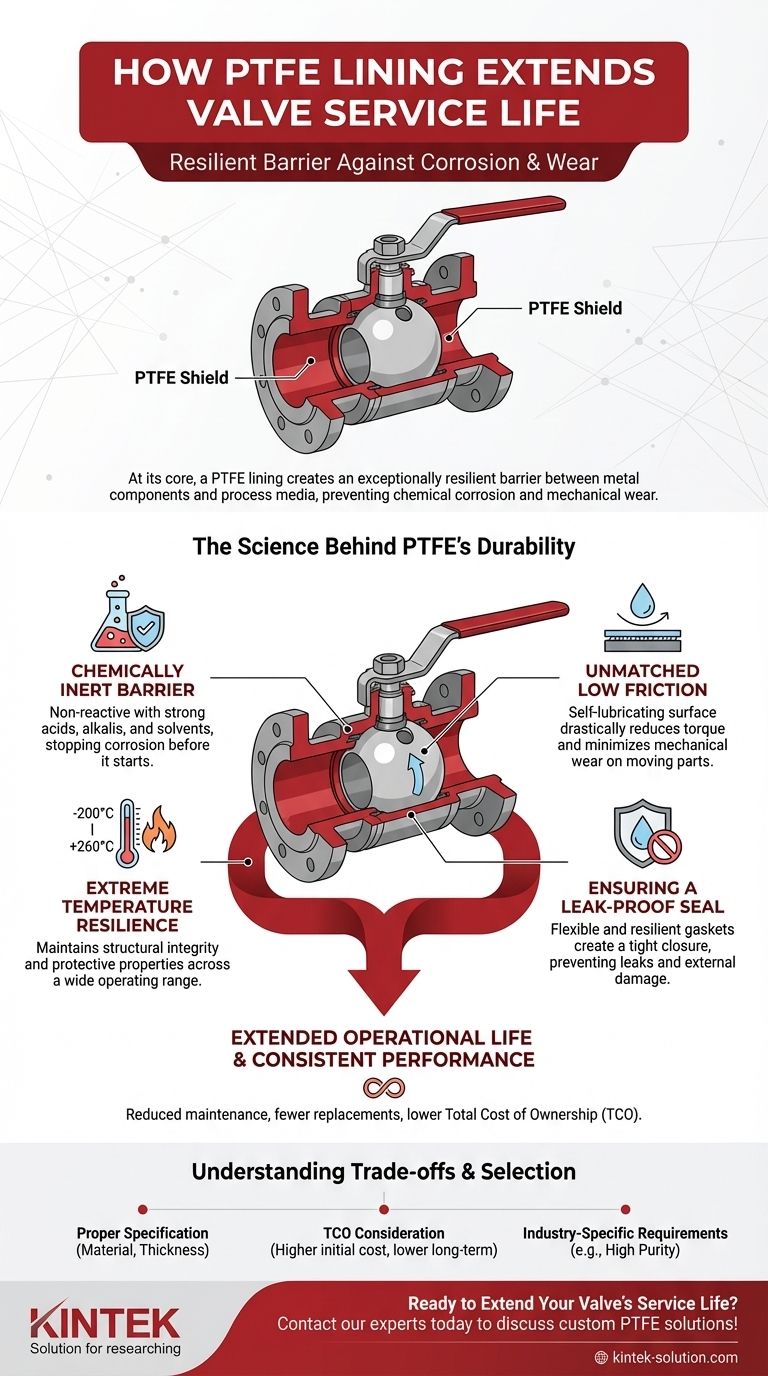

At its core, a PTFE lining extends a valve's service life by creating an exceptionally resilient barrier between the valve's metal components and the process media. This lining functions as a shield, preventing the two primary causes of valve failure: chemical corrosion and mechanical wear. By isolating the structural body of the valve from aggressive substances and reducing friction on moving parts, the PTFE ensures the valve maintains its structural integrity and sealing performance for a significantly longer duration.

A PTFE lining doesn't just add a single benefit; it provides a combination of chemical inertness, low friction, and temperature resistance. This trifecta systematically eliminates the root causes of valve degradation, making it a cornerstone of long-term reliability in demanding industrial applications.

The Science Behind PTFE's Durability

To truly understand how a PTFE lining extends service life, we must look at the specific material properties that contribute to its protective capabilities. It's not one feature, but a synthesis of several that deliver its remarkable performance.

A Chemically Inert Barrier

The most critical function of the PTFE lining is its near-total chemical inertness. It is non-reactive with a vast range of aggressive media.

This includes strong acids, powerful alkalis, strong oxidants, and virtually all organic solvents. Even aqua regia, a mixture capable of dissolving gold and platinum, does not affect PTFE.

By preventing direct contact, the lining stops chemical corrosion before it can begin, preserving the metal valve body and internal mechanisms from deterioration.

Unmatched Low Friction

PTFE has one of the lowest coefficients of friction of any known solid material, often compared to wet ice on wet ice. This creates a "self-lubricating" surface.

In valves with moving parts, like ball or plug valves, this property drastically reduces the torque needed for actuation and minimizes wear and tear on sealing surfaces during operation.

Less friction means less mechanical stress, less degradation of the sealing components, and a longer operational life with consistent performance.

Resilience Across Extreme Temperatures

A valve's protective lining is only effective if it remains stable under operational conditions. PTFE has a wide operating temperature range.

This thermal resistance ensures the lining does not become brittle at low temperatures or degrade at high temperatures.

It maintains its protective properties and structural integrity, preventing cracks or failures that would expose the underlying metal to the process media.

Ensuring a Leak-Proof Seal

Beyond lining the valve body, PTFE is frequently used for gaskets and seals. Its flexibility and resilience allow it to create a tight, durable seal.

This prevents leaks, which are not only a safety and environmental concern but also a source of external corrosion that can damage the valve and surrounding equipment.

A reliable seal is fundamental to a valve's function and longevity, and PTFE's properties make it an ideal material for this role.

Understanding the Trade-offs and Selection Criteria

While highly effective, a PTFE-lined valve is not a universal solution. Its success is entirely dependent on proper specification for the intended application. Making the right choice requires a clear understanding of your operational context.

The Importance of Proper Specification

The term "PTFE" can cover various formulations and thicknesses. Choosing the correct PTFE grade and lining specification is critical.

Factors like the specific chemical concentration, operating pressure, and temperature range must be carefully evaluated. An incorrect specification can lead to premature failure, defeating the purpose of the lining.

Considering Total Cost of Ownership

PTFE-lined valves may have a higher initial purchase price compared to standard unlined valves.

However, their extended service life and reduced need for maintenance, repairs, and replacement parts often result in a significantly lower total cost of ownership over the equipment's lifespan.

This is a key consideration in industries where downtime is extremely costly.

Industry-Specific Requirements

Different industries have unique demands. In pharmaceutical or food and beverage applications, the focus is on preventing contamination.

PTFE's inertness and smooth, non-porous surface are ideal for these high-purity applications, ensuring the process media is not contaminated by the valve materials.

Making the Right Choice for Your Application

Selecting the right valve comes down to aligning its capabilities with your primary operational goal.

- If your primary focus is handling aggressive chemicals: A PTFE-lined valve is the definitive choice for preventing chemical corrosion from strong acids, alkalis, or solvents.

- If your primary focus is high-cycle operations: The self-lubricating, low-friction nature of PTFE is critical for minimizing mechanical wear and ensuring long-term operational consistency.

- If your primary focus is minimizing maintenance and downtime: The long-term durability of a properly specified PTFE-lined valve makes it a sound strategic investment for reducing total cost of ownership.

By understanding these principles, you can confidently select a valve engineered for maximum longevity in your specific environment.

Summary Table:

| Key Benefit | How PTFE Lining Delivers | Impact on Valve Life |

|---|---|---|

| Chemical Inertness | Creates a non-reactive barrier against acids, alkalis, and solvents. | Prevents corrosion of metal components, preserving structural integrity. |

| Low Friction | Self-lubricating surface reduces wear on moving parts like balls and plugs. | Minimizes mechanical stress and degradation, extending operational consistency. |

| Temperature Resistance | Maintains integrity across a wide temperature range (-200°C to +260°C). | Prevents lining failure (cracking/brittleness) under extreme conditions. |

| Leak-Proof Sealing | Flexible PTFE gaskets and seals ensure tight, durable closures. | Eliminates leaks that cause external corrosion and equipment damage. |

Ready to Extend Your Valve's Service Life with Precision PTFE Components?

At KINTEK, we specialize in manufacturing high-performance PTFE liners, seals, and custom labware designed to withstand the most aggressive chemical environments. Whether you're in the semiconductor, medical, laboratory, or industrial sector, our components are engineered for maximum durability and reliability.

Let us help you:

- Reduce downtime with long-lasting, corrosion-resistant valves.

- Lower total cost of ownership by minimizing maintenance and replacements.

- Customize solutions from prototypes to high-volume orders.

Contact our experts today to discuss how our PTFE expertise can solve your specific valve challenges!

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

- Custom PTFE Square Trays for Industrial and Laboratory Use

- Customizable PTFE Seals Filter Holders for Versatile Applications

People Also Ask

- What are the main applications of PTFE type Teflon? Unlock Its Versatility for Your Industry

- What finishing techniques are effective for machined Teflon parts? Achieve Functional Performance and Dimensional Stability

- What chemical processing applications involve PTFE-machined parts? Essential Components for Corrosive & High-Purity Systems

- What factors should be considered when choosing between Nylon and PTFE? Select the Right Material for Your Application

- What are the unique properties of PTFE? Unlock Unmatched Performance in Demanding Applications