In the oil and gas industry, PTFE rotary shaft lip seals serve as a critical sealing solution for essential equipment operating under the sector's most punishing conditions. They are specifically engineered to prevent leaks in pumps, compressors, valves, and downhole tools where they are exposed to extreme temperatures, high pressures, and aggressive chemicals.

The core function of a PTFE seal is to provide unparalleled reliability where conventional elastomeric seals would fail. Its unique combination of chemical inertness, wide temperature tolerance, and low-friction performance makes it indispensable for ensuring the safety and efficiency of oil and gas operations.

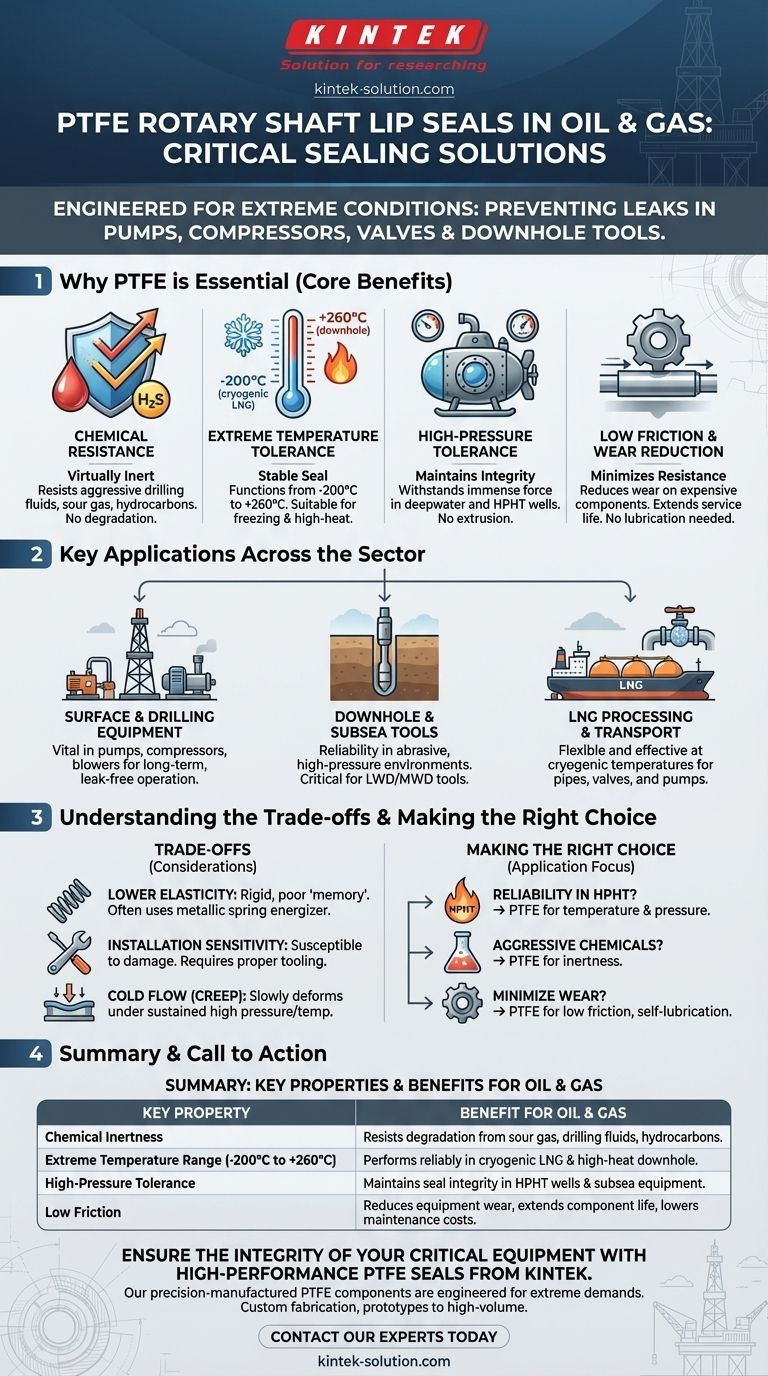

Why PTFE is Essential for Oil & Gas Operations

The selection of a sealing material is a critical engineering decision in the oil and gas industry, where equipment failure can have catastrophic consequences. PTFE (Polytetrafluoroethylene) is not just an option; it is often the only viable choice due to its inherent material properties.

Unmatched Chemical Resistance

PTFE is virtually inert to the vast majority of chemicals, including the aggressive drilling fluids, sour gas (H₂S), and hydrocarbons found in oil and gas extraction and processing. This prevents the seal from degrading, swelling, or failing due to chemical attack.

Extreme Temperature Tolerance

Operations can range from cryogenic temperatures in LNG (Liquefied Natural Gas) equipment to the extreme heat of downhole drilling. PTFE seals function effectively across an exceptionally wide temperature range, typically from -200°C to +260°C (-328°F to +500°F), ensuring a stable seal in both freezing and high-heat environments.

Performance Under High Pressure

From deepwater subsea equipment to High-Pressure/High-Temperature (HPHT) wells, seals must withstand immense force. The durability of PTFE allows it to maintain its integrity and sealing capability under high-pressure conditions without extrusion or damage.

Low Friction and Wear Reduction

PTFE possesses an extremely low coefficient of friction, allowing it to glide smoothly over rotating shafts with minimal resistance. This characteristic significantly reduces wear on expensive equipment components, extends the service life of both the seal and the shaft, and lowers maintenance costs. It also enables the seal to function effectively without lubrication, a critical advantage in many applications.

Key Applications Across the Sector

The versatility of PTFE seals allows them to be deployed across the entire oil and gas value chain, from upstream extraction to downstream processing.

Surface and Drilling Equipment

On the surface, PTFE seals are vital components in the pumps, compressors, and blowers that move fluids and gases. Their durability ensures long-term, leak-free operation, minimizing downtime for critical machinery.

Downhole and Subsea Tools

In downhole applications like Logging While Drilling (LWD) and Measurement While Drilling (MWD) tools, reliability is paramount. The cost of retrieving and repairing failed equipment is enormous. PTFE seals provide the long-term durability needed to survive these abrasive and high-pressure environments.

LNG Processing and Transport

For LNG facilities, which handle natural gas at cryogenic temperatures, material choice is crucial. PTFE's ability to remain flexible and effective at extreme low temperatures makes it an ideal sealing solution for pipes, valves, and pumps in the LNG supply chain.

Understanding the Trade-offs

While PTFE offers exceptional performance, it's important to understand its specific characteristics to ensure proper application. It is not a universal replacement for all other seal types.

Lower Elasticity vs. Elastomers

Compared to rubber-based (elastomeric) seals, PTFE is a more rigid material with poor "memory." It does not spring back into shape as readily. To compensate for this, PTFE lip seals are often designed with a metallic spring energizer that provides a constant force to maintain an effective seal.

Sensitivity to Installation

The rigidity of PTFE means that seals can be more susceptible to damage during installation if not handled correctly. Proper tooling and procedures are essential to avoid scratching or deforming the seal lip, which could compromise its performance.

Tendency for Cold Flow

Under sustained high pressure and temperature, PTFE can exhibit a phenomenon known as "creep" or "cold flow," where the material slowly deforms over time. This must be accounted for in the engineering design of the seal and its housing to ensure a long-lasting and reliable seal.

Making the Right Choice for Your Application

Selecting the correct seal is about matching the material's strengths to the operational demands.

- If your primary focus is reliability in HPHT environments: PTFE's combined tolerance for extreme temperatures and high pressures makes it the superior choice for downhole and subsea tools.

- If your primary focus is compatibility with aggressive chemicals: PTFE's near-universal chemical inertness is essential for equipment handling sour gas, harsh drilling muds, or refined products.

- If your primary focus is minimizing equipment wear and maintenance: The low-friction, self-lubricating nature of PTFE seals protects rotating shafts and extends service intervals, reducing operational costs.

Ultimately, leveraging PTFE's unique properties is key to ensuring operational integrity in the world's most demanding energy environments.

Summary Table:

| Key Property | Benefit for Oil & Gas |

|---|---|

| Chemical Inertness | Resists degradation from sour gas, drilling fluids, and hydrocarbons. |

| Extreme Temperature Range (-200°C to +260°C) | Performs reliably in cryogenic LNG and high-heat downhole environments. |

| High-Pressure Tolerance | Maintains seal integrity in HPHT wells and subsea equipment. |

| Low Friction | Reduces equipment wear, extends component life, and lowers maintenance costs. |

Ensure the integrity of your most critical oil and gas equipment with high-performance PTFE seals from KINTEK.

Our precision-manufactured PTFE components—including seals, liners, and labware—are engineered to meet the extreme demands of the semiconductor, medical, laboratory, and industrial sectors. We specialize in custom fabrication, from prototypes to high-volume orders, ensuring a perfect fit and unparalleled reliability for your specific application.

Contact our experts today to discuss your sealing challenges and discover how KINTEK's solutions can enhance your operational safety and efficiency.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

People Also Ask

- What are the best practices for achieving tight tolerances in Teflon (PTFE) machining? Master Precision for Demanding Applications

- What is PTFE commonly known as and what are its unique properties? Unlock Unmatched Chemical & Thermal Resistance

- What are the primary applications of PTFE fasteners and custom parts? Critical Solutions for Extreme Environments

- What are some common applications of machined PTFE? Leverage its Unique Properties for Demanding Applications

- What is the working temperature range of PTFE? Master Extreme Heat and Cryogenic Applications