In industrial settings, Teflon (PTFE) bushings are chosen for a precise set of material properties. They offer an exceptional combination of an extremely low-friction surface, high heat resistance across a wide temperature range, and broad chemical inertness. These characteristics make them a reliable solution for reducing wear, ensuring smooth operation, and protecting components in demanding environments where other materials would quickly fail.

The true value of a Teflon bushing isn't a single property, but its unique ability to solve multiple problems at once. It simultaneously reduces friction, resists chemical attack, and endures extreme temperatures, making it a "fit-and-forget" solution that enhances equipment reliability and longevity.

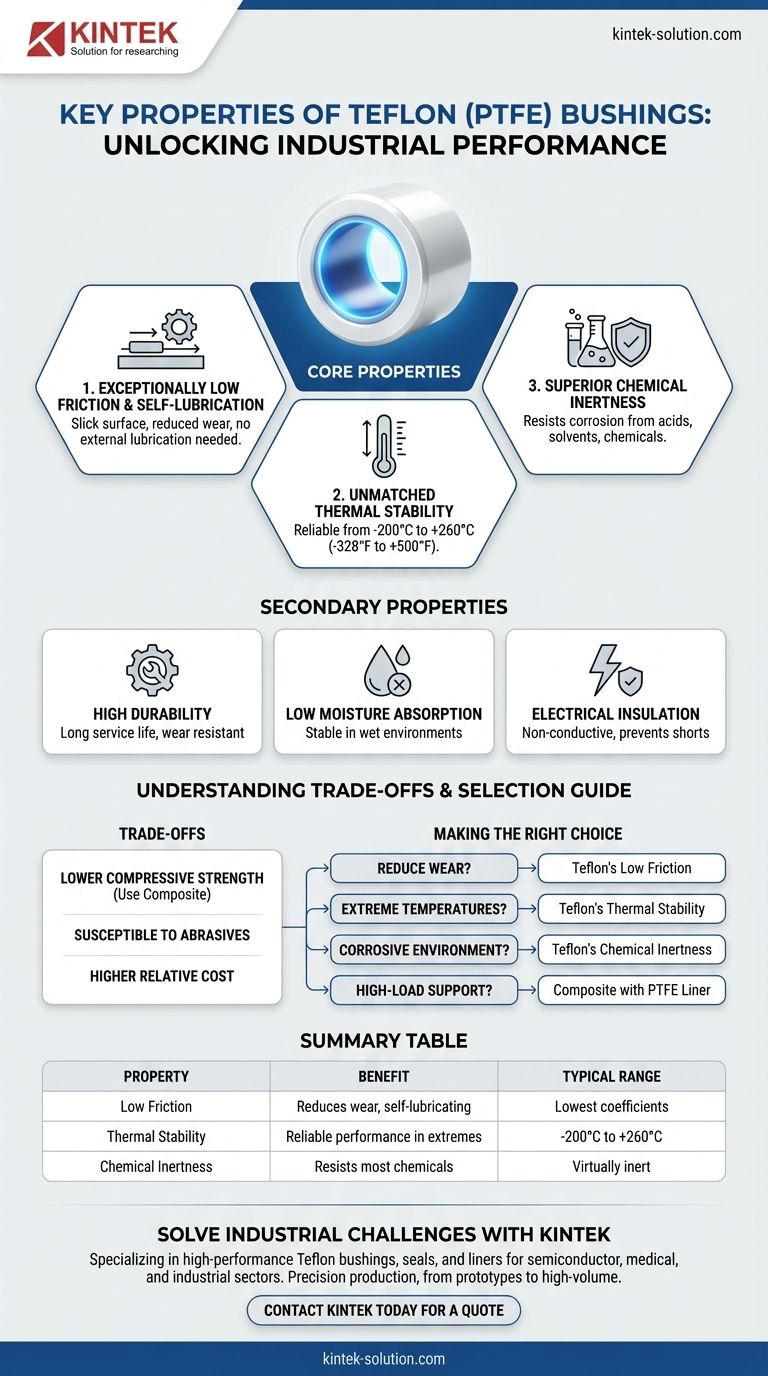

The Core Properties Driving Industrial Performance

The suitability of Polytetrafluoroethylene (PTFE) for industrial bushings stems from three primary characteristics. Understanding these properties explains why it is so widely specified for critical applications.

Exceptionally Low Friction and Self-Lubrication

PTFE has one of the lowest coefficients of friction of any solid material known. This creates an incredibly slick surface that allows parts to move with minimal resistance.

This property means the material is self-lubricating. It eliminates the need for external oil or grease, which can attract abrasive contaminants, break down at high temperatures, or be washed away in wet environments.

The direct result is smoother, more consistent motion, reduced energy consumption, and significantly less wear on mating shafts and housings.

Unmatched Thermal Stability

Teflon bushings perform reliably across an exceptionally wide temperature range, typically from -200°C to +260°C (-328°F to +500°F).

Unlike many plastics that become brittle at low temperatures or melt at high temperatures, PTFE retains its structural integrity and key properties. This makes it ideal for machinery operating in cryogenic applications, high-temperature processing ovens, or near engines.

Superior Chemical Inertness

PTFE is virtually inert and does not react with the vast majority of industrial chemicals, acids, and solvents.

This resistance to chemical attack prevents the corrosion, swelling, or degradation that would destroy metal or other plastic bushings. It ensures the bushing maintains its shape and performance, making it essential for equipment in chemical processing plants, food manufacturing, and pharmaceutical applications.

Secondary Properties That Broaden Applications

Beyond the primary three, other characteristics of PTFE make it a versatile problem-solver in specific industrial contexts.

High Durability and Wear Resistance

PTFE is a resilient plastic with high impact strength and excellent resistance to frictional wear, especially in sliding-contact scenarios. This durability translates directly to a long service life, reducing equipment downtime and maintenance costs.

Low Moisture Absorption

Teflon does not absorb water. Its dimensions and properties remain stable even when fully submerged or operating in high-humidity environments. This is a critical advantage over materials like nylon, which can swell and seize when exposed to moisture.

Electrical Insulation

As a non-conductive material, PTFE is an excellent electrical insulator. This property is valuable in applications where a bushing must mechanically support a component while also preventing electrical shorts between it and the surrounding structure.

Understanding the Trade-offs

No material is perfect. Acknowledging the limitations of PTFE is crucial for proper application and avoiding mis-specification.

Lower Compressive Strength

Compared to metals or harder plastics, PTFE is a relatively soft material. Under high, static loads, it can be susceptible to "creep," which is a slow, permanent deformation over time.

For this reason, high-load applications often use composite bushings—a metal shell (like steel or bronze) with a thin PTFE liner—to combine the strength of metal with the low friction of Teflon.

Susceptibility to Abrasives

While excellent for sliding wear, pure PTFE can be worn down by hard, sharp particles. In environments with significant abrasive contaminants, a different material or a "filled" grade of PTFE may be required.

Higher Relative Cost

PTFE is generally a more expensive polymer than common alternatives like Nylon or UHMW-PE. Its cost is justified by its unique combination of performance characteristics that other materials cannot match, especially in extreme environments.

Making the Right Choice for Your Application

To select the correct bushing, you must align the material's strengths with your primary operational goal.

- If your primary focus is reducing wear in high-speed motion: Teflon's self-lubricating, low-friction surface is your most critical asset, minimizing the need for external lubricants.

- If your primary focus is reliability in extreme temperatures: Its unmatched thermal stability from -200°C to +260°C ensures consistent performance where other plastics would fail.

- If your primary focus is surviving corrosive environments: Teflon's chemical inertness makes it the definitive choice for applications involving aggressive acids, solvents, or process chemicals.

- If your primary focus is high-load structural support: Consider a composite bushing with a PTFE liner to combine Teflon's low friction with a metal's superior compressive strength.

By understanding these core properties and their trade-offs, you can confidently specify Teflon bushings to increase the reliability and lifespan of your equipment.

Summary Table:

| Property | Benefit | Typical Range |

|---|---|---|

| Low Friction / Self-Lubricating | Reduces wear, eliminates need for external lubricants | One of the lowest coefficients of friction of any solid |

| Thermal Stability | Reliable performance in extreme temperatures | -200°C to +260°C (-328°F to +500°F) |

| Chemical Inertness | Resists corrosion from most acids, solvents, and chemicals | Virtually inert |

| High Durability & Wear Resistance | Long service life, reduced maintenance | Excellent for sliding-contact scenarios |

| Low Moisture Absorption | Stable performance in wet/humid environments | Does not absorb water |

| Electrical Insulation | Prevents electrical shorts | Non-conductive |

Ready to solve your toughest industrial challenges with precision-engineered PTFE components?

KINTEK specializes in manufacturing high-performance Teflon bushings, seals, liners, and custom labware for the semiconductor, medical, laboratory, and industrial sectors. We combine precision production with custom fabrication—from prototypes to high-volume orders—to deliver the reliability and longevity your equipment demands.

Contact KINTEK today to discuss your specific application needs and get a quote!

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Custom PTFE Teflon Balls for Advanced Industrial Applications

People Also Ask

- What makes PTFE reliable for sealing applications? Unmatched Chemical & Thermal Stability

- What is PTFE and what are its common applications? Discover the Versatile High-Performance Polymer

- What challenges are associated with machining PTFE? Overcoming Heat, Tolerances, and Safety

- What makes expanded PTFE gaskets easy to handle and install? Achieve a Perfect Seal on Any Flange

- What is the temperature range that PTFE instrumentation tube fittings can withstand? A Guide to Extreme Thermal Performance

- How are PTFE lip seals utilized in automotive applications? A Guide to Extreme Performance Sealing

- What flange types are PTFE envelope gaskets compatible with? Versatile Sealing for Every Industry

- How is a PTFE bearing pad installed on cast-in-place beams? Master the Critical Pre-Pour Integration