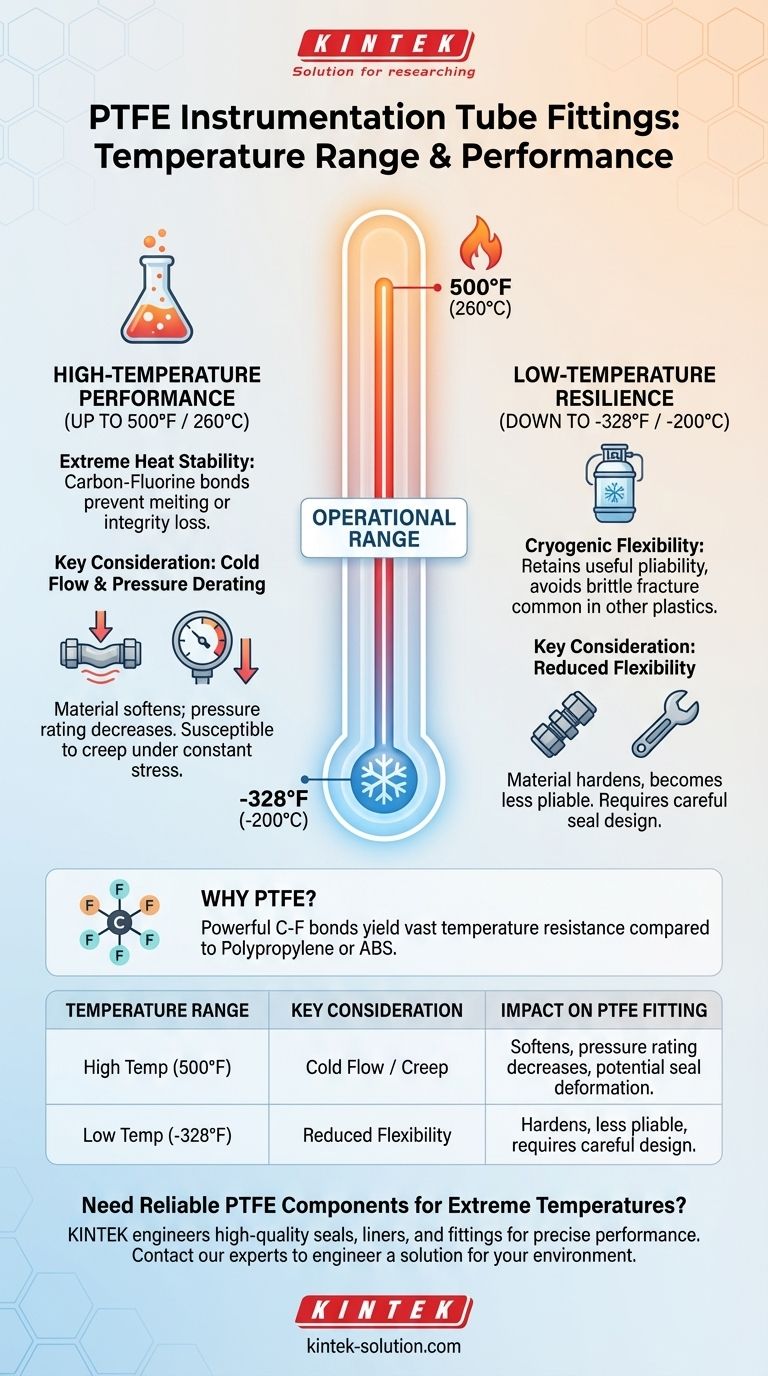

For instrumentation tube fittings, the safe and effective operating temperature range for Polytetrafluoroethylene (PTFE) is exceptionally wide. These components can typically withstand continuous service temperatures from approximately -328°F (-200°C) up to 500°F (260°C) without significant degradation, making them suitable for some of the most demanding thermal environments.

The key to successfully using PTFE fittings is understanding that while the material survives this vast temperature range, its mechanical properties—like hardness and resistance to deformation—change significantly at the extremes. This impacts how the fitting performs under pressure.

The Foundation of PTFE's Thermal Stability

PTFE's remarkable temperature resistance isn't accidental; it's a direct result of its unique molecular structure. This structure gives it distinct advantages at both high and low temperatures compared to nearly all other plastics and elastomers.

High-Temperature Performance

PTFE's ability to handle temperatures up to 500°F (260°C) is due to the powerful chemical bonds between its carbon and fluorine atoms.

This extreme stability means the material does not melt or lose its fundamental integrity when exposed to high heat within its operating range.

Low-Temperature Resilience

Unlike many polymers that become extremely brittle and fracture at low temperatures, PTFE retains a useful degree of flexibility down to cryogenic levels, around -328°F (-200°C).

This property makes it a critical material for applications involving liquefied gases and aerospace systems where other materials would fail.

How PTFE Compares to Other Plastics

The thermal performance of PTFE far exceeds that of common plastics like Polypropylene or ABS.

Its operational window is also significantly wider than most elastomers, which often have a much narrower range before they become brittle at low temperatures or degrade at high ones.

Understanding the Practical Trade-offs

A material's temperature rating is only part of the story. For a component like a tube fitting, which must maintain a seal under pressure, understanding how temperature affects its physical behavior is critical.

The Impact of Cold Flow (Creep)

PTFE is known for a phenomenon called cold flow, or creep. This is the tendency of the material to slowly deform over time when subjected to a constant mechanical stress, like the pressure from a tightened nut.

This effect is accelerated at higher temperatures. As PTFE approaches its upper limit, it becomes softer, increasing its susceptibility to creep and potentially compromising the long-term integrity of a seal.

Pressure Derating at High Temperatures

The maximum pressure a PTFE fitting can safely handle is not a static number. This pressure rating decreases as the operating temperature increases.

As the material softens with heat, its ability to resist pressure is reduced. It is essential to consult the manufacturer's pressure-temperature derating charts to ensure the fitting is not over-pressurized for its intended operating temperature.

Reduced Flexibility at Low Temperatures

While PTFE remains durable at cryogenic temperatures, it does become harder and significantly less flexible.

In applications requiring dynamic sealing or repeated assembly and disassembly in extreme cold, this reduced pliability must be factored into the design to ensure a reliable seal is achieved and maintained.

Making the Right Choice for Your System

Selecting the right material requires looking beyond the specifications on a data sheet and considering the entire operational context. Use these guidelines to inform your decision when considering PTFE.

- If your primary focus is high-temperature stability (up to 500°F / 260°C): PTFE is an excellent choice, but you must account for the material becoming softer and design for potential creep, especially under high mechanical loads.

- If your primary focus is cryogenic performance (down to -328°F / -200°C): PTFE's ability to avoid brittle failure is a major advantage, but ensure your design can create a tight seal with a harder, less pliable material.

- If your system involves a combination of high pressure and high temperature: Always verify that your operating conditions fall within the safe zone of the manufacturer's pressure-temperature derating curve.

Ultimately, understanding how temperature influences PTFE's mechanical behavior is the key to designing a safe and reliable system.

Summary Table:

| Temperature Range | Key Consideration | Impact on PTFE Fitting |

|---|---|---|

| High Temp: Up to 500°F (260°C) | Cold Flow / Creep | Material softens; pressure rating decreases; potential for seal deformation over time. |

| Low Temp: Down to -328°F (-200°C) | Reduced Flexibility | Material hardens; less pliable, requiring careful design to achieve a reliable seal. |

Need PTFE Components That Withstand Extreme Temperatures?

For semiconductor, medical, laboratory, and industrial applications, the precise performance of your PTFE components is non-negotiable. At KINTEK, we understand how temperature extremes affect material behavior.

We manufacture high-quality PTFE seals, liners, labware, and custom instrumentation fittings that are engineered for reliability across their entire thermal operating range. From prototypes to high-volume orders, our custom fabrication prioritizes precision to ensure your system's integrity under pressure and temperature stress.

Let's engineer a solution for your demanding environment. Contact our experts today to discuss your specific requirements.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Custom PTFE Square Trays for Industrial and Laboratory Use

People Also Ask

- What is PTFE commonly known as and what are its unique properties? Unlock Unmatched Chemical & Thermal Resistance

- What are the key benefits of PTFE in custom fabrication? Unlock Performance in Extreme Conditions

- What are the base characteristics of PTFE? Unlocking Extreme Performance in Friction, Temperature, and Chemical Resistance

- What is the working temperature range of PTFE? Master Extreme Heat and Cryogenic Applications

- What are the material advantages of machining Teflon? Unlock Unmatched Chemical & Thermal Resistance