In automotive engineering, PTFE lip seals are deployed in critical, high-stress environments where standard seals would fail. These specialized seals are found in high-RPM components like turbochargers and electric vehicle (EV) e-drives, demanding racing engines, fuel injection systems, and various fluid and steering assemblies.

The critical takeaway is that PTFE lip seals are not a universal replacement for standard seals; they are a specialized solution engineered for automotive applications that involve extreme rotational speeds, high temperatures, and aggressive chemicals—conditions that cause conventional elastomer seals to degrade and fail.

Why PTFE Excels in Extreme Automotive Conditions

The selection of a sealing material is dictated by its operating environment. Polytetrafluoroethylene (PTFE) possesses a unique combination of properties that make it the superior choice for the automotive industry's most challenging applications.

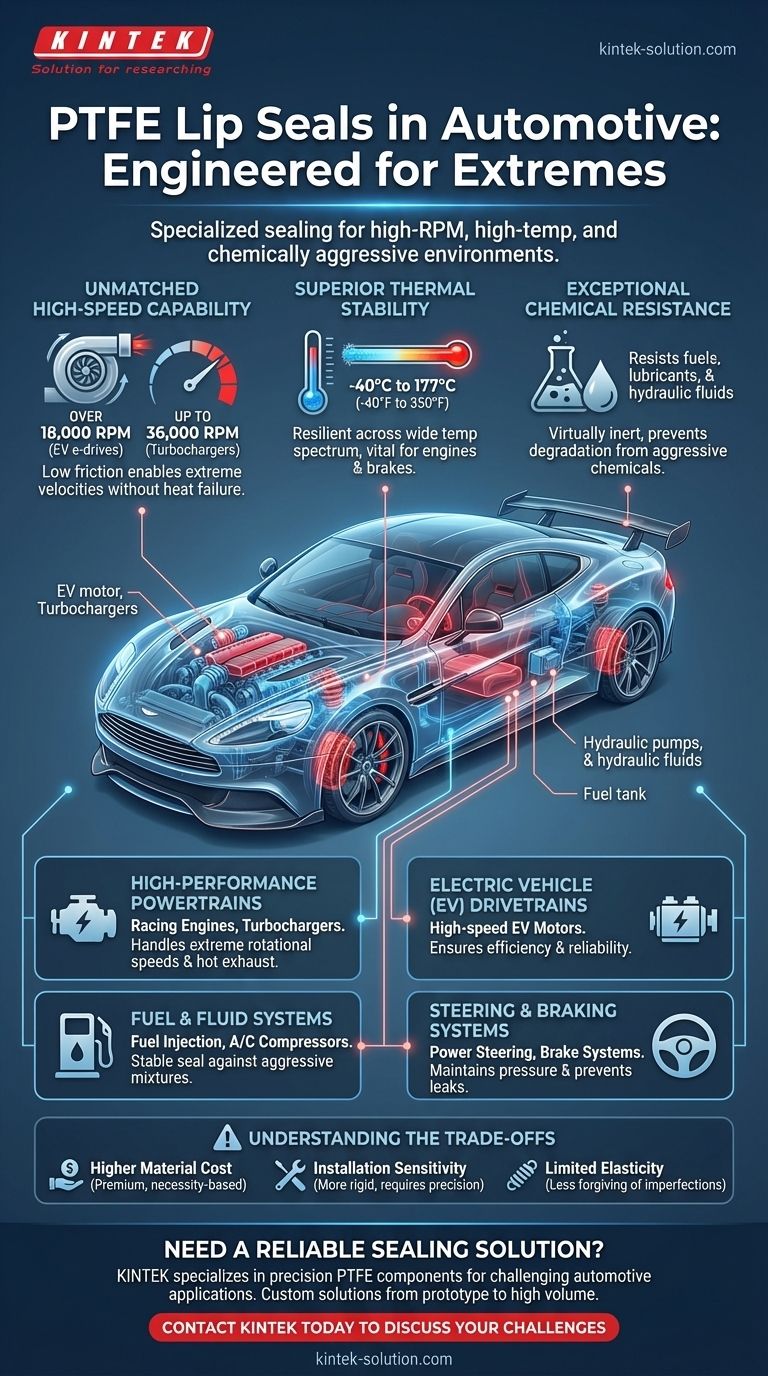

Unmatched High-Speed Capability

PTFE has an exceptionally low coefficient of friction. This allows it to seal rotating shafts at speeds that would generate destructive levels of heat and wear in a typical elastomer seal.

Applications like EV e-drives (over 18,000 RPM) and turbochargers (up to 36,000 RPM) rely on PTFE's ability to handle these velocities without failing, ensuring both performance and longevity.

Superior Thermal Stability

Automotive systems generate significant heat. PTFE seals are engineered to operate reliably across a wide temperature spectrum, typically from -40°C to 177°C (-40°F to 350°F).

This thermal resilience makes them indispensable in and around engine components, brake systems, and high-output compressors where temperature spikes are common.

Exceptional Chemical Resistance

PTFE is virtually inert to most chemicals. This property is vital in automotive applications where seals are constantly exposed to corrosive fuels, synthetic lubricants, hydraulic fluids, and chemical additives.

This resistance prevents the seal from swelling, hardening, or degrading over time, which is a common failure point for less robust materials in fuel injection pumps and A/C systems.

Key Automotive Applications in Detail

PTFE seals are integrated across a range of automotive systems, each leveraging the material's core strengths to solve a specific engineering problem.

High-Performance Powertrains

In racing engines (NASCAR, Indianapolis) and top-fuel blowers, the combination of extreme RPMs and intense heat is the norm. PTFE seals are essential for maintaining crankshaft and supercharger integrity under these punishing conditions.

Similarly, turbochargers rely on PTFE seals to manage high rotational speeds while containing hot exhaust gases and pressurized air.

Electric Vehicle (EV) Drivetrains

The high-speed motors found in modern EVs present a unique sealing challenge. The rotational speeds often exceed the limits of traditional rubber lip seals, making low-friction PTFE seals the standard for ensuring drivetrain efficiency and reliability.

Fuel and Fluid Systems

PTFE's chemical inertness is critical for fuel injection pumps and fuel cell systems, where it ensures a stable seal against aggressive fuel mixtures.

It is also used in air conditioning compressors and hydraulic systems, providing a durable barrier against specialized refrigerants and fluids that could compromise other materials.

Steering and Braking Systems

In power steering and brake systems, reliability is a matter of safety. PTFE seals provide a dependable, long-lasting seal for the hydraulic fluids used in these critical components, maintaining pressure and preventing leaks over the vehicle's lifespan.

Understanding the Trade-offs

While highly effective, PTFE seals are a specialized component, and their use involves specific considerations. Understanding these trade-offs is key to their successful application.

Higher Material Cost

PTFE is a premium engineering material. As a result, these seals are more expensive than their common elastomer counterparts, which is why their use is reserved for applications where their unique properties are a necessity, not a preference.

Installation Sensitivity

Compared to flexible rubber seals, PTFE seals are more rigid. This means installation requires greater care and precision. The shaft and bore surfaces must have a finer finish to ensure a proper seal is established and maintained.

Limited Elasticity

PTFE does not have the elastic "memory" of rubber. It conforms to the shaft upon installation but does not spring back in the same way. This makes it less forgiving of hardware imperfections like significant shaft runout or misalignment.

Making the Right Choice for Your Goal

Selecting the correct seal is a strategic decision based on the specific demands of the application.

- If your primary focus is high-RPM performance: PTFE seals are the definitive choice for applications like turbochargers and EV motors where speed and heat would destroy elastomer seals.

- If your primary focus is chemical compatibility: For components like fuel injection pumps or advanced hydraulic systems, PTFE's inertness provides unmatched reliability against aggressive fluids.

- If your primary focus is standard, cost-effective sealing: Conventional elastomer seals remain the best option for less demanding applications like static seals or low-speed shafts where extreme conditions are not a factor.

Ultimately, selecting a PTFE lip seal is a strategic engineering decision to guarantee reliability and performance where operational extremes are the norm.

Summary Table:

| Property | Benefit for Automotive Applications |

|---|---|

| Low Friction | Enables sealing at extreme RPMs (e.g., EV e-drives, turbochargers) |

| High-Temp Stability | Withstands temperatures from -40°C to 177°C (-40°F to 350°F) |

| Chemical Inertness | Resists degradation from fuels, lubricants, and hydraulic fluids |

Need a reliable sealing solution for a demanding automotive application?

KINTEK specializes in the precision manufacturing of high-performance PTFE components, including custom lip seals, for the most challenging environments in the semiconductor, medical, laboratory, and industrial sectors. Our expertise in custom fabrication—from prototypes to high-volume orders—ensures you get a seal engineered for superior performance, longevity, and reliability.

Contact KINTEK today to discuss how our PTFE seals can solve your high-speed, high-temperature, or chemically aggressive sealing challenges.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Custom PTFE Bottles for Diverse Industrial Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

People Also Ask

- Why is PTFE rod suitable for automotive applications? Boost Vehicle Performance & Durability

- What are the key considerations when machining Teflon? Master Precision Machining for Soft Polymers

- What tips can improve Teflon machining results? Master Sharp Tools, Heat Control, and Rigid Support

- What industries use PTFE machined parts and for what applications? Critical Components for Demanding Environments

- What are the best practices for achieving tight tolerances in Teflon (PTFE) machining? Master Precision for Demanding Applications