PTFE is exceptionally reliable for sealing due to a unique combination of three core properties: extreme chemical inertness, an incredibly wide operating temperature range, and a very low coefficient of friction. This molecular stability allows it to create and maintain a leak-proof seal in demanding industrial environments where most other materials would quickly degrade and fail.

The reliability of PTFE as a sealant stems directly from its molecular structure. The strong carbon-fluorine bonds create a highly stable, non-reactive material that can withstand extreme chemical, thermal, and mechanical stress without compromising its sealing integrity.

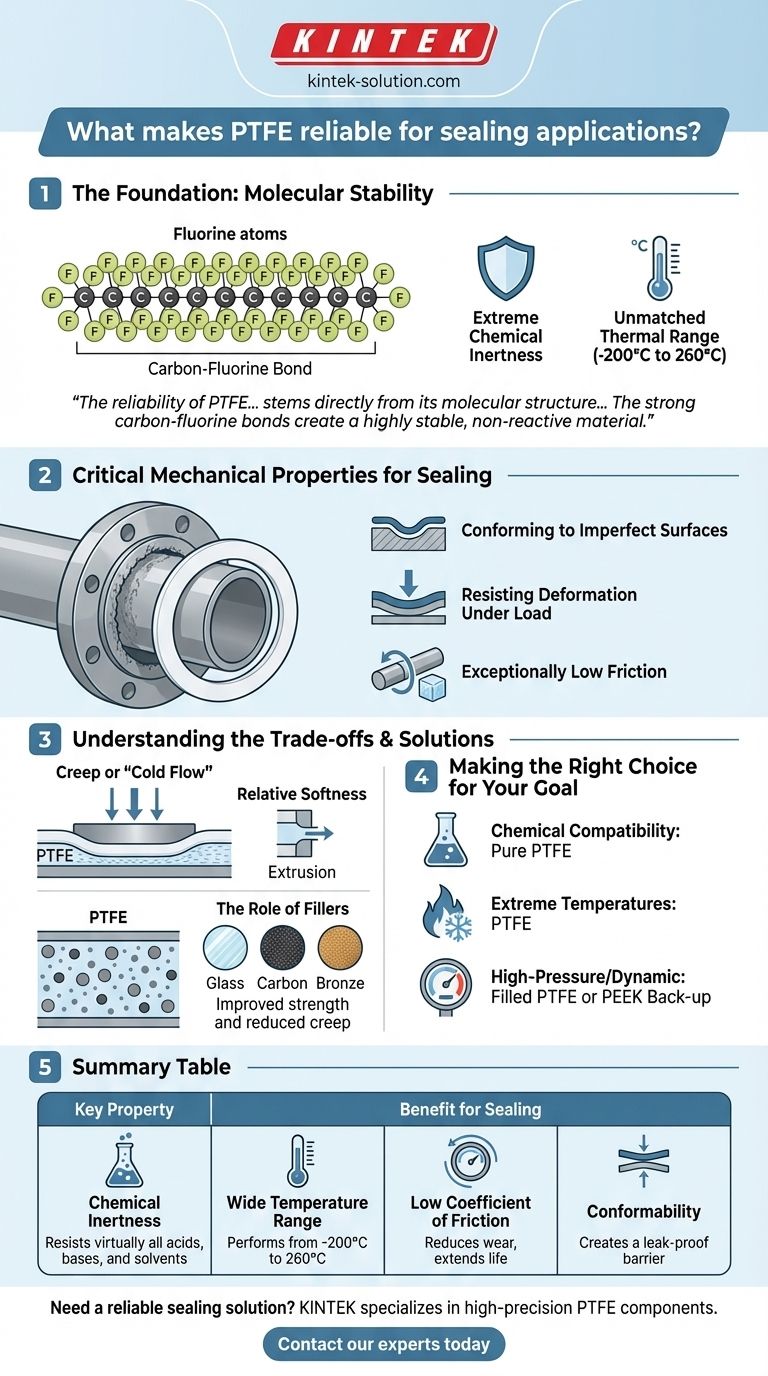

The Foundation of Reliability: Molecular Stability

The remarkable properties of PTFE (polytetrafluoroethylene) are not accidental; they are a direct result of its unique molecular architecture.

The Carbon-Fluorine Bond

At its core, PTFE consists of a long chain of carbon atoms completely shielded by a sheath of fluorine atoms.

The bond between carbon and fluorine is exceptionally strong and stable. This protective fluorine layer prevents other chemicals from attacking the vulnerable carbon backbone.

Consequence 1: Extreme Chemical Inertness

This molecular shield makes PTFE one of the most non-reactive substances known.

It is virtually immune to attack by almost all industrial chemicals, including aggressive acids, bases, and organic solvents. This ensures the seal material itself does not become a point of failure in corrosive environments.

Consequence 2: Unmatched Thermal Range

The strong C-F bonds also give PTFE incredible thermal stability, allowing it to function reliably from cryogenic temperatures (-200°C) up to high-heat applications (260°C / 500°F).

This bridges the critical gap where elastomeric seals become brittle or melt, but a full metal seal is not required.

Critical Mechanical Properties for Sealing

Beyond its inherent stability, PTFE possesses the physical characteristics necessary to form and hold a perfect seal.

Conforming to Imperfect Surfaces

Despite its strength, PTFE is a relatively soft material.

This softness allows it to deform slightly and flow into the microscopic imperfections, scratches, and uneven gaps present on mating surfaces like pipe flanges. This initial conformity is what creates the leak-proof barrier.

Resisting Deformation Under Load

Once seated, a PTFE seal exhibits minimal deformation under compressive load.

While it's soft enough to conform, it is also resilient enough to maintain its form and integrity under high pressure. This prevents the seal from being squeezed out of place, ensuring long-term, leak-free performance.

Exceptionally Low Friction

PTFE has one of the lowest coefficients of friction of any solid material, similar to wet ice on wet ice.

For dynamic applications, such as a seal on a rotating shaft, this non-stick, low-friction surface minimizes wear and heat generation, dramatically increasing the service life of the seal.

Understanding the Trade-offs

No material is perfect. Acknowledging the limitations of pure PTFE is crucial for proper application and design.

Creep or "Cold Flow"

Under a sustained, heavy load over time, pure PTFE can be susceptible to a phenomenon known as creep or cold flow. The material may slowly deform or "flow" away from the point of highest pressure.

Relative Softness

While beneficial for conforming to surfaces, PTFE's softness makes it prone to extrusion in very high-pressure applications. The material can be forced into the clearance gap between two sealed components.

The Role of Fillers

To counteract these limitations, PTFE is often blended with filler materials like glass, carbon, or bronze. These "filled PTFE" grades offer significantly improved resistance to creep and higher mechanical strength, making them suitable for more demanding high-pressure or structural roles.

Making the Right Choice for Your Goal

Selecting the correct sealing material depends entirely on the demands of the application.

- If your primary focus is chemical compatibility: Pure PTFE is often the default choice due to its near-universal inertness.

- If your primary focus is extreme temperatures: PTFE provides reliable sealing in conditions that would destroy common elastomers like rubber or silicone.

- If your primary focus is high-pressure or dynamic sealing: Consider a filled grade of PTFE or a design that incorporates a PEEK back-up ring to prevent extrusion.

Ultimately, PTFE's unique molecular stability makes it the definitive engineering solution for sealing challenges in the most demanding environments.

Summary Table:

| Key Property | Benefit for Sealing |

|---|---|

| Chemical Inertness | Resists virtually all acids, bases, and solvents. |

| Wide Temperature Range | Performs from -200°C to 260°C without degrading. |

| Low Coefficient of Friction | Reduces wear in dynamic applications, extending seal life. |

| Conformability | Flows into surface imperfections to create a leak-proof barrier. |

Need a reliable sealing solution for a demanding application? KINTEK specializes in manufacturing high-precision PTFE components, including seals, liners, and custom labware. Our expertise in custom fabrication—from prototypes to high-volume orders—ensures you get the exact PTFE or filled-PTFE seal you need for superior performance in semiconductor, medical, laboratory, and industrial environments.

Contact our experts today to discuss your specific requirements and get a solution that guarantees reliability.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Teflon Balls for Advanced Industrial Applications

People Also Ask

- What is one weakness of PTFE gaskets and sheets? Understanding Creep and Cold Flow

- Why are Teflon bushings suitable for food processing applications? Ensure Food Safety and Efficiency

- How does the low friction coefficient of PTFE coatings affect tightening torque? Achieve Accurate Clamping Force Safely

- Why is chemical resistance important for impeller materials? Ensure Pump Reliability and Purity

- What are the recommended methods for preparing metal surfaces before bonding with PTFE? Achieve a Durable, High-Strength Bond

- How is TFE (tetrafluoroethylene) produced? A Guide to the High-Temperature Synthesis Process

- What are the performance specifications of PTFE-lined bearings? Achieve Maintenance-Free, High-Load Performance

- What makes PTFE washers ideal for high and low temperature applications? Ensuring Reliable Performance in Extreme Environments