Properly installing a PTFE seal is a methodical process that is absolutely critical to its performance and lifespan. The key steps involve meticulously preparing the hardware, carefully handling and aligning the seal, applying precise and even force during installation, and verifying the final placement to prevent the most common failure modes like leakage and premature wear.

The success of a PTFE seal depends less on force and more on precision. Because PTFE is a soft, deformable material, the entire installation process must focus on creating a perfect, uncontaminated sealing interface without distorting the seal itself.

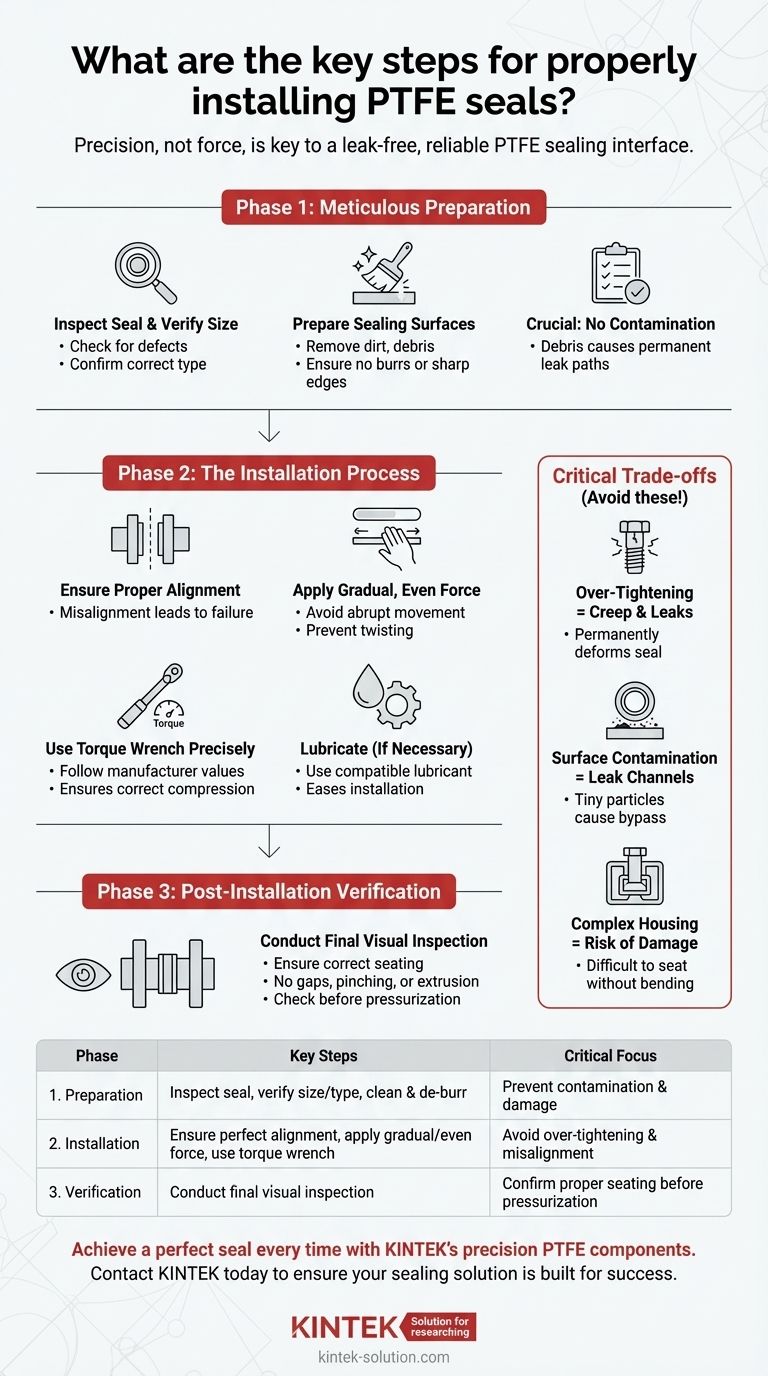

Phase 1: Meticulous Preparation

Before the seal even approaches the hardware, proper preparation is the foundation for a reliable outcome. Skipping these steps is a primary cause of seal failure.

Inspect the Seal First

Before you begin, carefully inspect the new PTFE seal for any nicks, scratches, or manufacturing defects. A damaged seal cannot be expected to perform correctly and should be discarded.

Verify Correct Size and Type

Confirm that you have the exact seal specified for the application. Using a seal that is even slightly the wrong size or made from an inappropriate grade of PTFE will lead to inevitable leaks.

Prepare the Sealing Surfaces

All mating surfaces, such as flanges or glands, must be perfectly clean. Remove all dirt, dust, oily residues, and debris.

Crucially, inspect for and remove any burrs, weld spatter, or sharp edges. These imperfections can easily damage the soft PTFE material during and after installation, creating a leak path.

Phase 2: The Installation Process

Handling the seal correctly during the physical installation is where precision becomes paramount. PTFE is not a forgiving material like rubber.

Ensure Proper Alignment

The seal must be perfectly aligned with the sealing surfaces. Misalignment causes uneven pressure, leading to localized wear, deformation, and eventual failure.

Apply Gradual, Even Force

Never use forceful, abrupt movements to push a seal into place. Installation should be a gradual process. If the seal is being fitted into a complex machined pocket, avoid excessive twisting or bending that could cause permanent structural damage.

Lubricate If Necessary

In some cases, a very light application of an approved lubricant can ease the installation process. However, ensure the lubricant is compatible with both the system media and the PTFE material.

Use the Right Tools and Torque

For applications involving fasteners, such as flange gaskets, using a torque wrench is non-negotiable. Follow the manufacturer's recommended torque values and tightening patterns precisely. This ensures the correct compressive load is applied evenly across the seal.

Understanding the Critical Trade-offs

The unique properties of PTFE create specific failure points that you must actively work to avoid.

The Danger of Over-Tightening

This is the single most common mistake. Unlike elastomers that spring back, PTFE will "creep" or cold-flow when over-compressed. Over-tightening permanently deforms the seal, thinning it out and forcing material away from the sealing area, which guarantees a leak.

The Risk of Surface Contamination

The emphasis on cleaning is because the soft PTFE sealing line is highly vulnerable. A tiny metal shaving or piece of grit left on a flange face will be pressed into the seal, creating a permanent channel for fluid to bypass.

The Impact of Housing Design

The design of the hardware itself plays a role. Simple housings with features like flanges or retainers simplify installation. In contrast, complex, deep pockets can make it difficult to seat the seal without bending or damaging it, increasing the risk of an improper fit.

Phase 3: Post-Installation Verification

Your work isn't finished once the seal is in place. A final check is required to confirm a successful installation.

Conduct a Final Visual Inspection

Visually inspect the installed seal. Ensure it is sitting correctly between the mating parts, with no visible gaps, pinching, or extrusion. It should look uniform and properly seated in its gland or on its flange. This is your last chance to spot a problem before the system is pressurized.

How to Apply This to Your Project

Your primary goal will determine where you focus the most attention during the installation process.

- If your primary focus is maximum long-term reliability: Your priorities are meticulous surface preparation and the precise use of a torque wrench to achieve the specified compression.

- If your primary focus is a complex installation (e.g., a deep machined pocket): Your priorities are gradual, even insertion and using specialized installation tools or cones to prevent the seal from being bent or damaged.

- If your primary focus is a high-pressure or critical application: You must verify that the housing design itself is suited for PTFE and pay extreme attention to avoiding any over-tightening.

Ultimately, treating the installation of a PTFE seal as a precision task, not a brute-force one, is the key to achieving a perfect, leak-free connection.

Summary Table:

| Phase | Key Steps | Critical Focus |

|---|---|---|

| 1. Preparation | Inspect seal, verify size/type, clean and de-burr surfaces | Prevent contamination and damage |

| 2. Installation | Ensure perfect alignment, apply gradual/even force, use correct torque | Avoid over-tightening and misalignment |

| 3. Verification | Conduct a final visual inspection | Confirm proper seating before pressurization |

Achieve a perfect seal every time with KINTEK's precision PTFE components.

Proper installation is critical, but it starts with a high-quality, precisely manufactured seal. KINTEK specializes in custom PTFE fabrication for the semiconductor, medical, laboratory, and industrial sectors. We ensure our seals, liners, and labware are manufactured to the exacting tolerances required for a successful, reliable installation in your most demanding applications.

Whether you need prototypes or high-volume orders, our expertise guarantees a component that fits perfectly and performs flawlessly.

Contact KINTEK today to discuss your project requirements and ensure your sealing solution is built for success.

Visual Guide

Related Products

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Teflon Balls for Advanced Industrial Applications

People Also Ask

- What are the characteristics of Teflon washers? Unlock Superior Slipperiness & Chemical Resistance

- In which industries are PTFE gland packings commonly used? For Purity, Chemical Resistance & Reliability

- What installation methods are available for PTFE slide bearings? Choose the Right Method for Your Structure

- What are the main features of PTFE bellow mechanical seals? A Guide to Extreme Chemical Resistance and Reliability

- Why is the quality of PTFE resin important for structured and expanded PTFE? Ensure Long-Term Sealing Integrity

- What are the recommended conditions for hardening bonded PTFE? Achieve a Strong, Stress-Free Bond

- What tools and processes are involved in machining PTFE? A Guide to Precision Manufacturing

- What are the advantages of using Expanded PTFE sheet gasket material? Superior Sealing for Demanding Applications