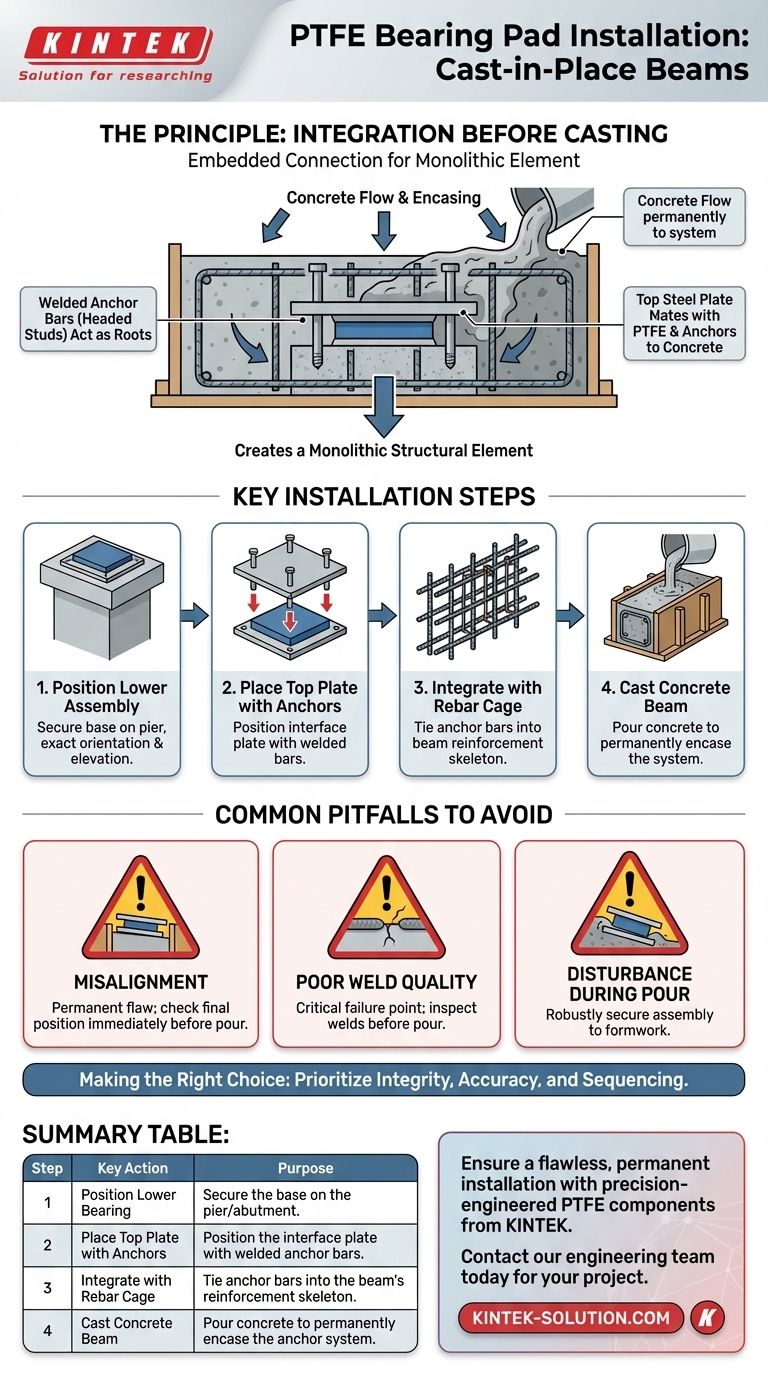

To correctly install a PTFE bearing pad on a cast-in-place beam, the process relies on creating a mechanical connection before the concrete is ever poured. The bearing's top steel plate has anchor bars welded to it, which are then integrated with the beam's rebar cage and permanently embedded during the on-site concrete casting.

The core principle for a cast-in-place beam is fundamentally different from a prefabricated one. You are not attaching the bearing to a finished component; you are building the bearing into the beam as it is being formed, creating a single, monolithic structural element.

The Principle: Integration Before Casting

The challenge with a cast-in-place (CIP) beam is that the final structural element—the concrete beam itself—does not exist at the time of bearing installation. Therefore, methods like epoxy bonding or bolting, which are common for connecting to existing concrete, are not applicable.

Why Cast-in-Place Requires an Embedded Connection

For CIP construction, the connection must be established within the formwork. The bearing becomes part of the pre-pour assembly, just like the reinforcing steel.

The goal is to physically lock the bearing's top plate into the concrete mass, ensuring that any forces are transferred through this mechanical interlock rather than a surface bond.

The Role of the Top Steel Plate

The top steel plate of the PTFE bearing serves as the crucial interface. Its bottom surface mates with the PTFE layer to allow movement, while its top surface is designed to be permanently anchored into the concrete superstructure above it.

The Welded Anchor System

The most common and reliable method is to weld steel anchor bars (or headed studs) onto the top face of the bearing's upper steel plate.

These bars act like roots, extending up into the space that will soon be filled with concrete, providing a robust mechanical grip once the concrete cures.

Key Installation Steps

A successful installation hinges on correct sequencing and precise positioning within the beam's formwork.

1. Position the Lower Bearing Assembly

First, the lower part of the bearing pad is set and secured on the prepared surface of the pier or abutment. Its position, orientation, and elevation must be exact according to the structural plans.

2. Prepare and Place the Top Plate

The top steel plate, with its anchor bars already welded on, is placed onto the lower assembly. The entire bearing is temporarily secured to prevent movement during subsequent construction.

3. Integrate with Beam Reinforcement

The anchor bars extending from the bearing's top plate are now tied directly into the main reinforcing steel cage of the beam. This step physically connects the bearing to the beam's structural skeleton before the concrete pour.

4. Cast the Concrete Beam

With the bearing and rebar cage securely in place, the formwork is closed and the concrete is poured. The concrete flows around the anchor bars and the edges of the top plate, fully encasing the connection system.

Common Pitfalls to Avoid

While the method is straightforward, the permanence of the connection means that installation errors are difficult and costly to correct.

Misalignment is Permanent

The bearing's position is locked in once the concrete cures. Any error in its location or alignment within the formwork will be a permanent flaw in the structure, potentially compromising its performance and service life.

Poor Weld Quality

The welds connecting the anchor bars to the top steel plate are a critical load transfer point. Insufficient or low-quality welds can become a point of failure, making weld inspection a vital quality control step before the pour.

Disturbance During the Pour

The bearing assembly must be robustly secured within the formwork. If it is displaced by the force of the flowing concrete, the final position will be incorrect.

Making the Right Choice for Your Goal

- If your primary focus is structural integrity: Prioritize the quality and inspection of the welds on the anchor bars, as this is the fundamental load-transfer mechanism into the beam.

- If your primary focus is construction accuracy: Triple-check the bearing's final position, elevation, and orientation within the formwork immediately before the concrete pour, as no adjustments are possible afterward.

- If your primary focus is project sequencing: Ensure the bearing is set and integrated with the rebar cage early in the process, getting it approved before scheduling the concrete delivery to avoid costly delays.

By embedding the bearing directly into the cast-in-place beam, you create an exceptionally robust and unified structural system designed for decades of service.

Summary Table:

| Step | Key Action | Purpose |

|---|---|---|

| 1 | Position Lower Bearing | Secure the base on the pier/abutment. |

| 2 | Place Top Plate with Anchors | Position the interface plate with welded anchor bars. |

| 3 | Integrate with Rebar Cage | Tie anchor bars into the beam's reinforcement skeleton. |

| 4 | Cast Concrete Beam | Pour concrete to permanently encase the anchor system. |

Ensure a flawless, permanent installation with precision-engineered PTFE components from KINTEK.

For cast-in-place beams, the quality of the PTFE bearing and its integrated anchor system is paramount to structural integrity. KINTEK specializes in manufacturing high-performance PTFE seals, liners, and custom components for the construction, industrial, and civil engineering sectors. Our expertise in custom fabrication—from prototypes to high-volume orders—ensures you get a bearing solution that guarantees precise alignment and long-term reliability.

Don't leave this critical connection to chance. Contact our engineering team today to discuss your project's specific requirements.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Customizable PTFE Rods for Advanced Industrial Applications

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

People Also Ask

- What are the main advantages of using PTFE parts in industrial applications? Unlock Unmatched Chemical Resistance and Reliability

- What are the key advantages of PTFE? Unmatched Performance for Extreme Environments

- Why is CNC machining preferred for Teflon parts over other methods? Unlock Precision & Complex Designs

- What are the future considerations for machining Teflon? Mastering Material Challenges with Smart Tech

- Why is PTFE rod suitable for automotive applications? Boost Vehicle Performance & Durability