At their core, PTFE envelope gaskets are designed for versatility. They are compatible with a broad range of flange materials, including glass-lined, cast iron, metal, concrete, rubber, plastic, and enamel flanges. Their unique construction also makes them exceptionally effective for sealing non-standard or irregular flange surfaces where a high-performance seal is critical.

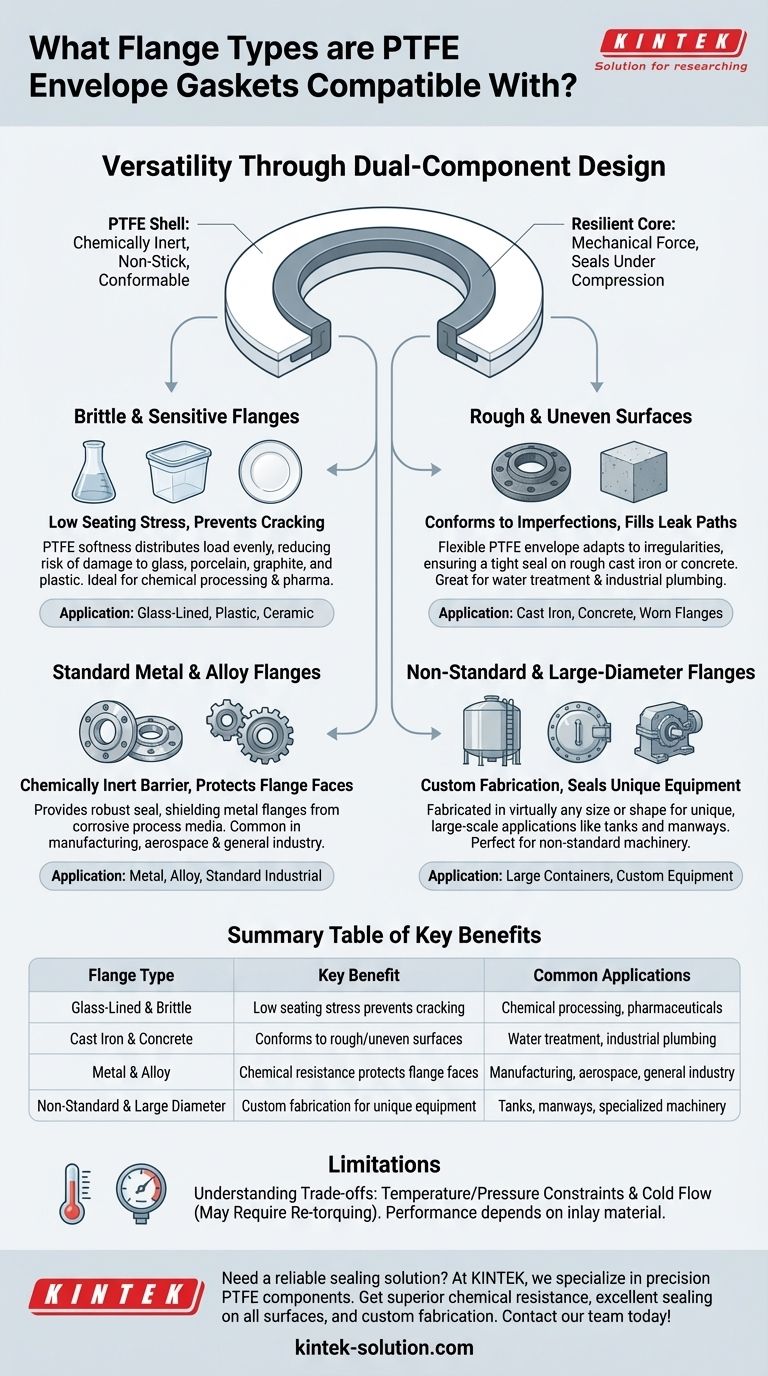

The key to the PTFE envelope gasket's wide compatibility is its dual-component design: a chemically inert, non-stick PTFE shell protects a resilient inner core. This combines the universal chemical resistance of PTFE with the mechanical sealing properties of the inlay material, creating a solution for the most challenging flange connections.

Why PTFE Envelope Gaskets are So Versatile

The effectiveness of a PTFE envelope gasket stems from its intelligent, composite structure. It is not a single material but a system designed to overcome common sealing challenges.

The Dual-Component Advantage

A PTFE envelope gasket consists of two parts: the outer PTFE "envelope" and an inner "inlay" or core material.

The PTFE shell provides a non-stick, chemically inert contact surface. The inner core provides the mechanical force and resilience needed to create and maintain the seal under compression.

Superior Chemical Inertness

PTFE is one of the most chemically resistant materials known. It is virtually immune to acids, corrosive media, and a vast range of industrial chemicals.

This makes the gasket ideal for applications in chemical processing, pharmaceuticals, and any system handling aggressive fluids where protecting the flange and preventing contamination is paramount.

Adaptability to Surface Imperfections

The soft, conformable nature of the PTFE shell, combined with the resilience of its core, allows the gasket to flow into minor surface imperfections.

This is why it performs so well on flanges that are not perfectly smooth, such as those made from cast iron or concrete, or on older flanges that may have some wear.

Key Flange Compatibility Categories

Different flange types present unique sealing challenges. PTFE envelope gaskets are engineered to address a wide spectrum of these issues.

For Brittle and Sensitive Flanges

Materials like glass, porcelain, graphite, and plastic are prone to cracking or damage under the high compressive loads required by many conventional gaskets.

The softness of the PTFE envelope distributes the load more evenly, achieving a reliable seal at a lower seating stress and significantly reducing the risk of damaging the flange.

For Rough or Uneven Surfaces

Cast iron and concrete flanges often have surfaces that are inherently rough or uneven.

The flexible nature of the PTFE envelope gasket allows it to conform to these irregularities, filling in potential leak paths and ensuring a tight, long-lasting seal where a rigid gasket would fail.

For Standard Metal and Alloy Flanges

In standard industrial applications like plumbing, manufacturing, and aerospace, PTFE envelope gaskets provide a robust seal for metal and alloy flanges.

Their primary benefit here is creating an effective barrier against liquid contaminants while protecting the metal flange faces from corrosive process media.

For Non-Standard and Large-Diameter Flanges

These gaskets can be fabricated in virtually any size or shape, making them a go-to solution for non-standard equipment.

This includes sealing large-diameter containers, tanks, manways, and gearbox end covers where off-the-shelf gaskets are not an option.

Understanding the Trade-offs and Limitations

While highly versatile, no sealing solution is perfect for every scenario. Understanding the limitations of PTFE is critical for proper application.

Temperature and Pressure Constraints

The performance of the gasket is dictated by both the PTFE shell and, more importantly, the inlay material.

Standard PTFE has temperature limitations. While suitable for many applications, extreme high-temperature or high-pressure environments require selecting a gasket with a specialized core material designed to handle those conditions.

Creep and Cold Flow

PTFE has a tendency to "creep" or cold flow, meaning it can slowly deform over time when under a constant compressive load.

The gasket's inner core is designed to resist this, but it is a factor to consider in applications with high bolt loads or significant temperature cycling. Periodic re-torquing of bolts may be necessary to maintain seal integrity.

Making the Right Choice for Your Application

Selecting the correct gasket is about matching its properties to your specific operational needs.

- If your primary focus is corrosion resistance: The inert PTFE shell provides unparalleled protection for both the flange and the process media.

- If your primary focus is sealing brittle materials: This gasket's ability to seal at low seating stress makes it the safest choice for glass, plastic, or ceramic flanges.

- If your primary focus is dealing with irregular flange surfaces: The gasket's conformability provides a reliable seal on uneven, worn, or non-standard flanges where other options might fail.

Ultimately, choosing a PTFE envelope gasket is an investment in reliability and equipment protection across a wide range of demanding industrial applications.

Summary Table:

| Flange Type | Key Benefit | Common Applications |

|---|---|---|

| Glass-Lined & Brittle Flanges | Low seating stress prevents cracking | Chemical processing, pharmaceuticals |

| Cast Iron & Concrete Flanges | Conforms to rough/uneven surfaces | Water treatment, industrial plumbing |

| Metal & Alloy Flanges | Chemical resistance protects flange faces | Manufacturing, aerospace, general industry |

| Non-Standard & Large Diameter | Custom fabrication for unique equipment | Tanks, manways, specialized machinery |

Need a reliable sealing solution for your specific flange application?

At KINTEK, we specialize in manufacturing precision PTFE components—including custom envelope gaskets—for semiconductor, medical, laboratory, and industrial applications. Our expertise ensures you get a gasket that provides:

- Superior chemical resistance to protect your equipment

- Excellent sealing performance on both standard and irregular surfaces

- Custom fabrication from prototypes to high-volume orders

Let us help you solve your toughest sealing challenges. Contact our team today for a consultation and quote!

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

- Custom PTFE Square Trays for Industrial and Laboratory Use

- Custom PTFE Volumetric Flasks for Advanced Scientific and Industrial Use

People Also Ask

- What are the future considerations for machining Teflon? Mastering Material Challenges with Smart Tech

- How does PTFE contribute to low friction and wear resistance? Achieve Superior Performance with Advanced Materials

- What tips can improve Teflon machining results? Master Sharp Tools, Heat Control, and Rigid Support

- What are the key advantages of PTFE? Unmatched Performance for Extreme Environments

- Why is CNC machining preferred for Teflon parts over other methods? Unlock Precision & Complex Designs