The fundamental reason expanded PTFE (ePTFE) gaskets are easy to handle is their unique combination of softness, high compressibility, and form-in-place convenience. Unlike rigid, pre-cut gaskets, ePTFE is easily cut by hand or machine, allowing technicians to create a perfect, custom-sized seal for virtually any flange directly on-site with minimal effort.

The core challenge in any sealing application is achieving a perfect fit, especially on older or imperfect surfaces. The true value of ePTFE is not just that it's easy to install, but that its physical properties inherently solve this challenge by conforming precisely to surface irregularities to create a more reliable and durable seal.

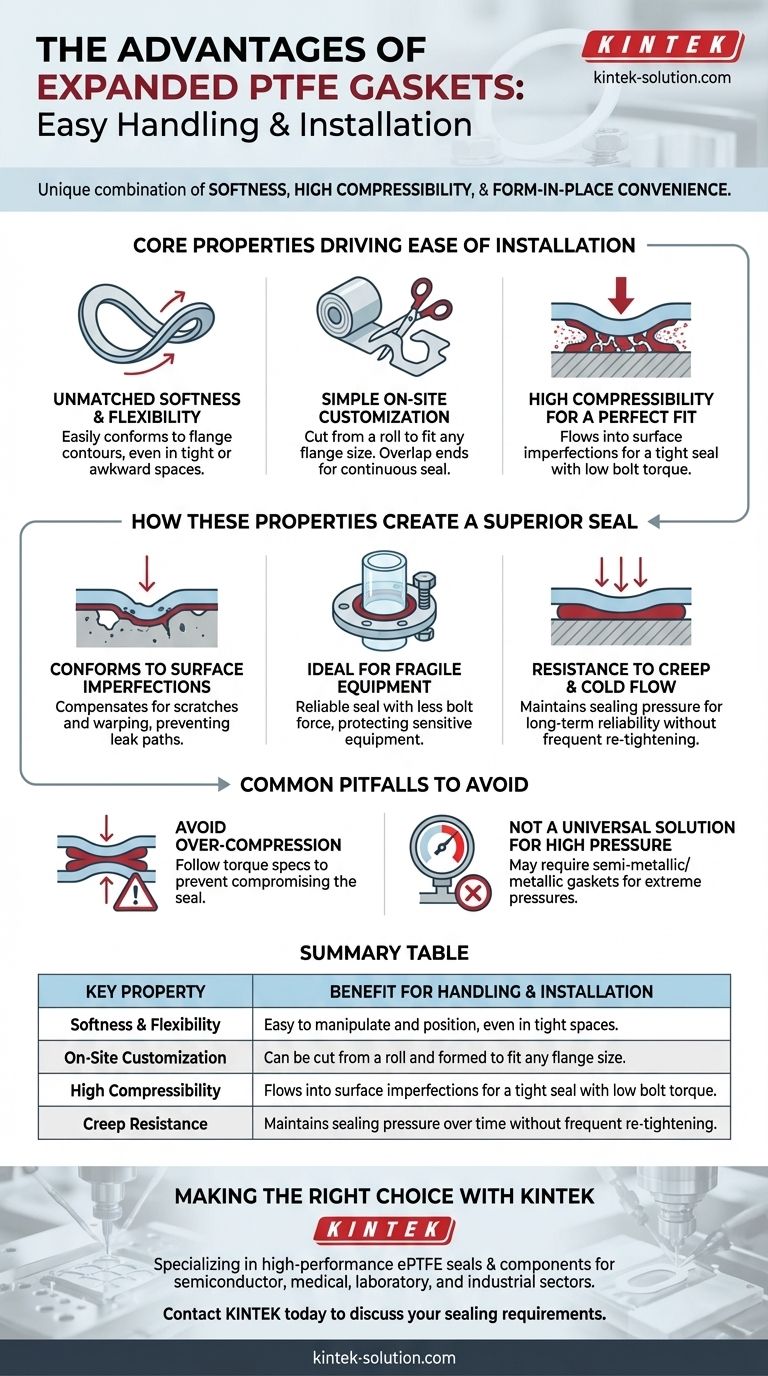

The Core Properties Driving Ease of Installation

The unique manufacturing process of ePTFE creates a microporous structure of fibers that gives it distinct physical advantages over solid, or "pure," PTFE and other gasket materials.

Unmatched Softness and Flexibility

Expanded PTFE is exceptionally soft and pliable. This makes it easy to manipulate and position, even in tight or awkward spaces.

This inherent flexibility allows it to follow the contours of a flange face without cracking or requiring excessive force.

Simple On-Site Customization

One of the most significant advantages of ePTFE is that it can be cut and shaped on the job. Technicians can simply cut the required length from a roll and form it into place.

For large or non-standard flanges, the ends can be overlapped to create a continuous gasket of any size, dramatically simplifying inventory and preparation.

High Compressibility for a Perfect Fit

When compressed by an external force, like tightening flange bolts, the internal fibers of ePTFE entangle and densify.

This high compressibility allows the material to flow into and fill microscopic cracks, voids, and grooves on the sealing interface, ensuring a tight fit with relatively low bolt torque.

How These Properties Create a Superior Seal

The ease of handling ePTFE is directly linked to its effectiveness as a sealing material. The properties that simplify installation are the same ones that ensure a leak-free, long-lasting connection.

Conforming to Surface Imperfections

No flange surface is perfectly flat. ePTFE's ability to compress and conform to irregularities is its greatest strength.

It effectively compensates for scratches, pitting, and warping, preventing the small leak paths that can cause problems for more rigid gasket types.

Ideal for Fragile Equipment

The softness and high compressibility of ePTFE mean a reliable seal can be achieved with less bolt force.

This makes it an excellent choice for delicate or stress-sensitive equipment, such as glass-lined, ceramic, or plastic flanges, where excessive torque could cause damage.

Resistance to Creep and Cold Flow

A known weakness of pure PTFE is its tendency to "creep" or cold flow under pressure, causing the seal to loosen over time.

Expanded PTFE has a multi-directional fibrous structure that gives it excellent resistance to creep. It maintains its shape and sealing pressure, ensuring long-term reliability without the need for frequent re-tightening.

Common Pitfalls to Avoid

While ePTFE is highly versatile, its properties make it better suited for some applications than others. Understanding its limitations is key to successful implementation.

Avoid Over-Compression

The material's softness can lead to over-compression if excessive bolt torque is applied. This can squeeze the gasket out of the flange joint, compromising the seal.

It is critical to follow the manufacturer's torque specifications to achieve the optimal balance of compression and material integrity.

Not a Universal Solution for High Pressure

While excellent for a vast range of chemical and temperature applications, the inherent softness of ePTFE means it may not be the first choice for extremely high-pressure systems.

In these cases, semi-metallic or metallic gaskets may be required to provide the necessary rigidity and blowout resistance.

Making the Right Choice for Your Application

Selecting the right gasket depends entirely on the demands of the specific joint. ePTFE offers a unique blend of performance and convenience that solves many common sealing challenges.

- If your primary focus is sealing older, damaged, or warped flanges: The outstanding compressibility of ePTFE makes it the ideal choice to create a tight seal on imperfect surfaces.

- If your primary focus is reducing gasket inventory and simplifying fieldwork: The ability to cut and form ePTFE on-site for any flange size makes it exceptionally versatile and cost-effective.

- If your primary focus is sealing fragile or stress-sensitive equipment: ePTFE achieves a reliable seal with lower bolt torque, protecting your equipment from damage.

Ultimately, ePTFE's properties work in unison to simplify the installation process while simultaneously increasing the reliability of the final seal.

Summary Table:

| Key Property | Benefit for Handling & Installation |

|---|---|

| Softness & Flexibility | Easy to manipulate and position, even in tight spaces. |

| On-Site Customization | Can be cut from a roll and formed to fit any flange size. |

| High Compressibility | Flows into surface imperfections for a tight seal with low bolt torque. |

| Creep Resistance | Maintains sealing pressure over time without frequent re-tightening. |

Struggling with leaks from imperfect flanges or fragile equipment?

KINTEK specializes in manufacturing high-performance expanded PTFE (ePTFE) seals and components. Our ePTFE gaskets offer the softness, compressibility, and on-site customization detailed in this article, providing a reliable, long-lasting seal for your most challenging applications in the semiconductor, medical, laboratory, and industrial sectors.

We offer custom fabrication from prototypes to high-volume orders, ensuring you get the perfect seal for your specific needs.

Contact KINTEK today to discuss your sealing requirements and let our precision manufacturing solve your installation challenges.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

People Also Ask

- How is PTFE used in industrial processes? Maximize Safety and Efficiency

- Why is PTFE considered a significant discovery? A Material That Revolutionized Industry

- What are some important physical property values for PTFE? Master Its Extreme Performance for Demanding Applications

- What is the temperature range that PTFE can withstand? From -200°C to +260°C for Demanding Applications

- What are some applications of CNC machined PTFE parts? Critical Components for Medical, Electrical & Food Industries