In high-stakes sealing applications, PEEK (polyether ether ketone) backup rings provide unparalleled support in environments defined by extreme pressure and high temperatures. Their primary advantages stem from immense mechanical strength, rigidity, and superior wear resistance, making them the default choice for demanding hydraulic systems, high-pressure valves, and critical components in the aerospace and automotive industries.

The decision to use a PEEK backup ring is a strategic choice for mechanical integrity. While other materials may offer broader chemical resistance or lower friction, PEEK is chosen when the primary failure risk is the physical extrusion of a seal under extreme force and heat.

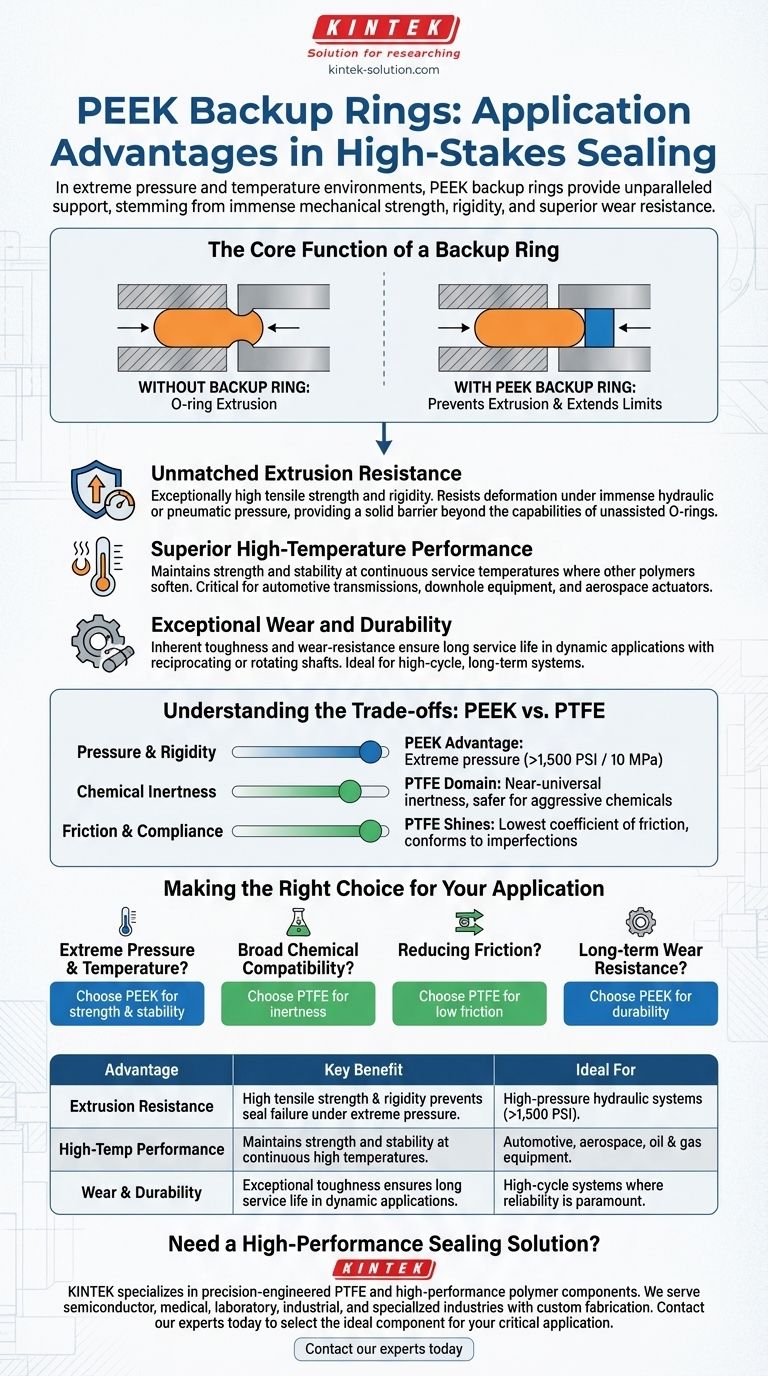

The Core Function of a Backup Ring

Before analyzing materials, it's crucial to understand the role of a backup ring. Its sole purpose is to support a softer elastomeric seal, like an O-ring, in a high-pressure system.

Under pressure, a soft O-ring can be forced into the small gap between mating metal components, a failure known as extrusion. A backup ring sits in this gap and, being made of a harder material, physically blocks the O-ring from extruding, thereby extending the pressure and temperature limits of the entire sealing system.

Why PEEK Excels: A Material Property Breakdown

PEEK's advantages are not arbitrary; they are directly tied to its fundamental material properties. It is an engineered solution for the most severe mechanical sealing challenges.

Unmatched Extrusion Resistance

PEEK possesses exceptionally high tensile strength and rigidity. This means it resists deformation even under immense hydraulic or pneumatic pressure.

Where a softer material might deform and allow a seal to leak, a PEEK ring holds its shape, providing a solid barrier. This is why it is specified for systems operating at pressures well beyond the capability of unassisted O-rings.

Superior High-Temperature Performance

PEEK maintains its strength and stability at continuous service temperatures where many other polymers would soften or degrade.

This thermal stability is critical in applications like automotive transmissions, downhole oil and gas equipment, and aerospace hydraulic actuators, where high operating temperatures are unavoidable.

Exceptional Wear and Durability

In dynamic applications involving reciprocating or rotating shafts, seals are subject to constant friction and wear. PEEK's inherent toughness and wear-resistant characteristics ensure a long service life.

This makes it ideal for high-cycle, long-term systems where maintenance is difficult and reliability is paramount.

Understanding the Trade-offs: PEEK vs. PTFE

To truly understand PEEK's value, it must be compared to the other common backup ring material, PTFE (polytetrafluoroethylene). The choice is a matter of selecting the right tool for the job.

Pressure and Rigidity: PEEK's Advantage

PEEK is significantly stronger and more rigid than PTFE. If your primary challenge is containing extreme pressure (typically above 1,500 PSI / 10 MPa), PEEK provides the most robust defense against extrusion.

Chemical Inertness: PTFE's Domain

While PEEK has very good chemical resistance, PTFE is nearly universally inert. For applications involving highly aggressive chemicals, such as strong acids or alkalis, PTFE is the safer choice.

Friction and Compliance: Where PTFE Shines

PTFE has one of the lowest coefficients of friction of any solid material. In dynamic seals where minimizing friction and stick-slip is a priority, a PTFE backup ring is superior. Its softness also allows it to conform more easily to imperfections.

Making the Right Choice for Your Application

Your selection should be dictated by the most significant challenge your sealing system faces.

- If your primary focus is extreme pressure and temperature resistance: Choose PEEK for its unmatched strength, rigidity, and thermal stability.

- If your primary focus is broad chemical compatibility: Choose PTFE for its near-universal inertness, especially with aggressive media.

- If your primary focus is reducing friction in a dynamic seal: Choose PTFE for its exceptionally low coefficient of friction.

- If your primary focus is long-term wear resistance in a high-cycle system: Choose PEEK for its superior durability and mechanical toughness.

By matching the material's core strengths to your application's specific demands, you ensure optimal performance and system reliability.

Summary Table:

| Advantage | Key Benefit | Ideal For |

|---|---|---|

| Extrusion Resistance | High tensile strength & rigidity prevents seal failure under extreme pressure. | High-pressure hydraulic systems (>1,500 PSI). |

| High-Temperature Performance | Maintains strength and stability at continuous high temperatures. | Automotive transmissions, aerospace actuators, oil & gas equipment. |

| Wear & Durability | Exceptional toughness ensures long service life in dynamic applications. | High-cycle systems where reliability is paramount. |

Need a High-Performance Sealing Solution?

When your application demands reliability under extreme pressure and temperature, the right component makes all the difference. KINTEK specializes in manufacturing precision-engineered PTFE and high-performance polymer components, including seals, liners, and labware.

We serve the semiconductor, medical, laboratory, industrial, and other specialized industries, prioritizing precision production while offering custom fabrication from prototypes to high-volume orders.

Let us help you select or fabricate the ideal component for your critical application.

Contact our experts today to discuss your specific requirements and discover how we can enhance your system's performance and longevity.

Visual Guide

Related Products

- Customizable PTFE Seals Filter Holders for Versatile Applications

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

People Also Ask

- How do PTFE properties benefit butterfly valve performance? Enhance Durability & Efficiency

- What material is the PTFE bottle made from? Discover the Benefits of 100% Virgin PTFE

- How does PTFE behave in terms of chemical inertness? Unmatched Resistance for Demanding Applications

- What are the chemical resistance properties of PTFE labware? The Ultimate Guide to Inert Labware

- What makes the PTFE bottle durable? Unmatched Chemical & Thermal Stability for Demanding Applications