Graphite PTFE gland packing is a composite sealing material that combines the distinct properties of two materials: Polytetrafluoroethylene (PTFE) and graphite. It is manufactured from a PTFE yarn that has fine graphite particles integrated into its structure, creating a packing that leverages the strengths of both components for demanding industrial applications.

The core purpose of graphite PTFE packing is to solve a critical weakness of pure PTFE. While PTFE offers supreme chemical resistance, it fails in high-speed applications due to poor heat dissipation. By embedding graphite, the packing gains the thermal conductivity and lubricity needed to handle high shaft speeds without overheating or scoring.

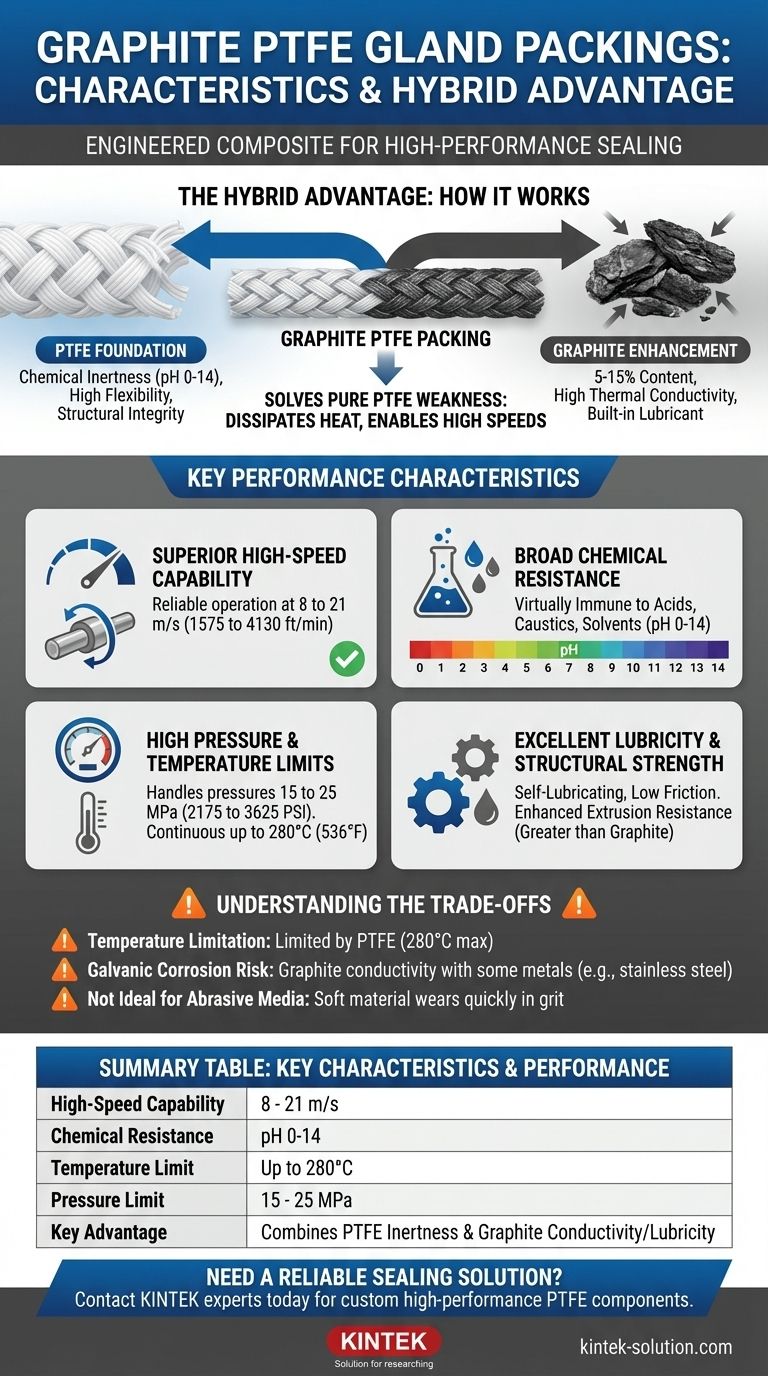

The Hybrid Advantage: How It Works

Graphite PTFE packing is not simply a mixture; it is an engineered composite designed to deliver performance where the individual components would fall short. Understanding its dual nature is key to using it effectively.

The PTFE Foundation

The packing's base is a braided yarn made from PTFE, a synthetic polymer renowned for its unique properties. This foundation provides the packing's structural integrity and its primary defense against chemical attack. Key characteristics from the PTFE include exceptional chemical inertness (pH range of 0-14) and high flexibility.

The Graphite Enhancement

During manufacturing, 5-15% graphite content is encapsulated within the PTFE yarn. This is not just a surface coating. The graphite particles provide two critical performance boosts that pure PTFE lacks.

First, they dramatically increase thermal conductivity, allowing the packing to draw frictional heat away from the rotating shaft and dissipate it through the stuffing box. This prevents the packing from burning and the shaft from scoring.

Second, the graphite acts as a built-in solid lubricant. This lowers the coefficient of friction well below that of pure PTFE, reducing both wear on the shaft and the energy needed to drive the equipment.

Key Performance Characteristics

The blend of these materials results in a packing with a versatile and powerful set of operational characteristics, making it a go-to choice for many challenging sealing environments.

Superior High-Speed Capability

The excellent thermal conductivity allows graphite PTFE packing to operate reliably at high linear speeds, typically in the range of 8 to 21 m/s (1575 to 4130 ft/min). This makes it ideal for centrifugal pumps and other rotating equipment where pure PTFE would quickly fail.

Broad Chemical Resistance

By retaining the chemical nature of its PTFE base, this packing is virtually immune to all but the most aggressive chemicals, such as molten alkali metals. It is stable across the entire pH range of 0-14, making it suitable for acids, caustics, solvents, and oils.

High Pressure and Temperature Limits

Graphite PTFE packing is designed for demanding conditions. It can handle pressures from 15 to 25 MPa (2175 to 3625 PSI) and continuous temperatures up to 280°C (536°F), a significant improvement over many synthetic packings.

Excellent Lubricity and Low Friction

The self-lubricating properties of the embedded graphite minimize friction and prevent the stick-slip phenomenon common with other materials. This ensures smooth operation and extends the service life of both the packing and the equipment shaft.

Enhanced Structural Strength

While pure graphite packing can be brittle and has low tensile strength (around 650 PSI), the braided PTFE yarn gives this composite packing far greater structural strength and extrusion resistance. This allows it to hold a seal effectively without deforming under pressure.

Understanding the Trade-offs

No sealing material is perfect for every application. Being aware of the limitations of graphite PTFE is essential for ensuring operational reliability and avoiding premature failure.

Temperature Limitation vs. Pure Graphite

While its 280°C limit is high for a polymer-based packing, it is determined by the PTFE component. In applications with temperatures exceeding this limit, pure flexible graphite packing, which can handle temperatures over 450°C (or much higher in non-oxidizing environments), is the necessary choice.

Potential for Galvanic Corrosion

Graphite is electrically conductive. In the presence of an electrolyte (like water), this conductivity can create a galvanic cell with certain stainless steel shafts, potentially leading to pitting and corrosion of the shaft over time. This risk is a known factor for all graphite-based packings and should be considered during material selection.

Not Ideal for Abrasive Media

The relative softness of both PTFE and graphite makes this packing a poor choice for applications involving abrasive slurries, such as mining or wastewater containing significant grit. The abrasive particles will quickly wear away the packing material, leading to leakage.

Making the Right Choice for Your Application

Selecting the correct packing material is critical for maximizing equipment uptime and ensuring safety. Use these guidelines to determine if graphite PTFE is the right fit.

- If your primary focus is high-speed pumps with clean fluids: This packing is an ideal choice, offering the thermal dissipation and lubricity needed for long service life.

- If your primary focus is broad chemical resistance in dynamic applications: The pH 0-14 range combined with pressure and speed capabilities makes this one of the most versatile chemical packings available.

- If your application has extreme temperatures (above 280°C / 536°F): You must select a pure flexible graphite packing to avoid material degradation.

- If your shaft is sensitive to galvanic corrosion or the media is ultra-pure: A pure, non-graphite PTFE packing may be a safer choice, provided the shaft speed and temperature are within its lower limits.

Ultimately, choosing graphite PTFE packing is a decision for high-performance reliability in applications that are too demanding for pure PTFE but do not require the extreme temperature resistance of pure graphite.

Summary Table:

| Key Characteristic | Performance Detail |

|---|---|

| High-Speed Capability | 8 to 21 m/s (1575 to 4130 ft/min) |

| Chemical Resistance | pH range of 0-14 (acids, caustics, solvents) |

| Temperature Limit | Up to 280°C (536°F) continuously |

| Pressure Limit | 15 to 25 MPa (2175 to 3625 PSI) |

| Key Advantage | Combines PTFE's chemical inertness with graphite's thermal conductivity & lubricity |

Need a Reliable Sealing Solution for Your High-Performance Equipment?

Graphite PTFE gland packings are engineered for demanding applications in the semiconductor, medical, laboratory, and industrial sectors. At KINTEK, we specialize in the precision manufacturing of high-quality PTFE components, including custom gland packings.

We understand that every application is unique. Whether you need a prototype for testing or a high-volume order for production, our custom fabrication services ensure you get the exact sealing solution your equipment requires.

Let us help you enhance your operational reliability and efficiency. Contact our experts today to discuss your specific needs and get a quote!

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Bottles for Diverse Industrial Applications

People Also Ask

- What materials are used to construct Teflon bearing pads? The Key Components for Structural Support

- What industries commonly use PTFE bellows and diaphragms, and why? Ensure Purity & Chemical Resistance

- Why is Teflon difficult to machine to tight tolerances? Overcome Material Instability

- What are the key benefits of PTFE coatings? Achieve Unmatched Performance in Extreme Conditions

- What CNC machining techniques are suitable for Teflon (PTFE)? Master Precision with Specialized Methods

- How do PTFE and NBR oil seals compare in terms of flexibility and installation? Choose the Right Seal for Your Application

- What are the basic materials used in slide bearings? Explore PTFE, Composites & Multi-Layer Designs

- What post-machining treatments are applied to Teflon parts? Stabilize and Clean, Don't Modify.