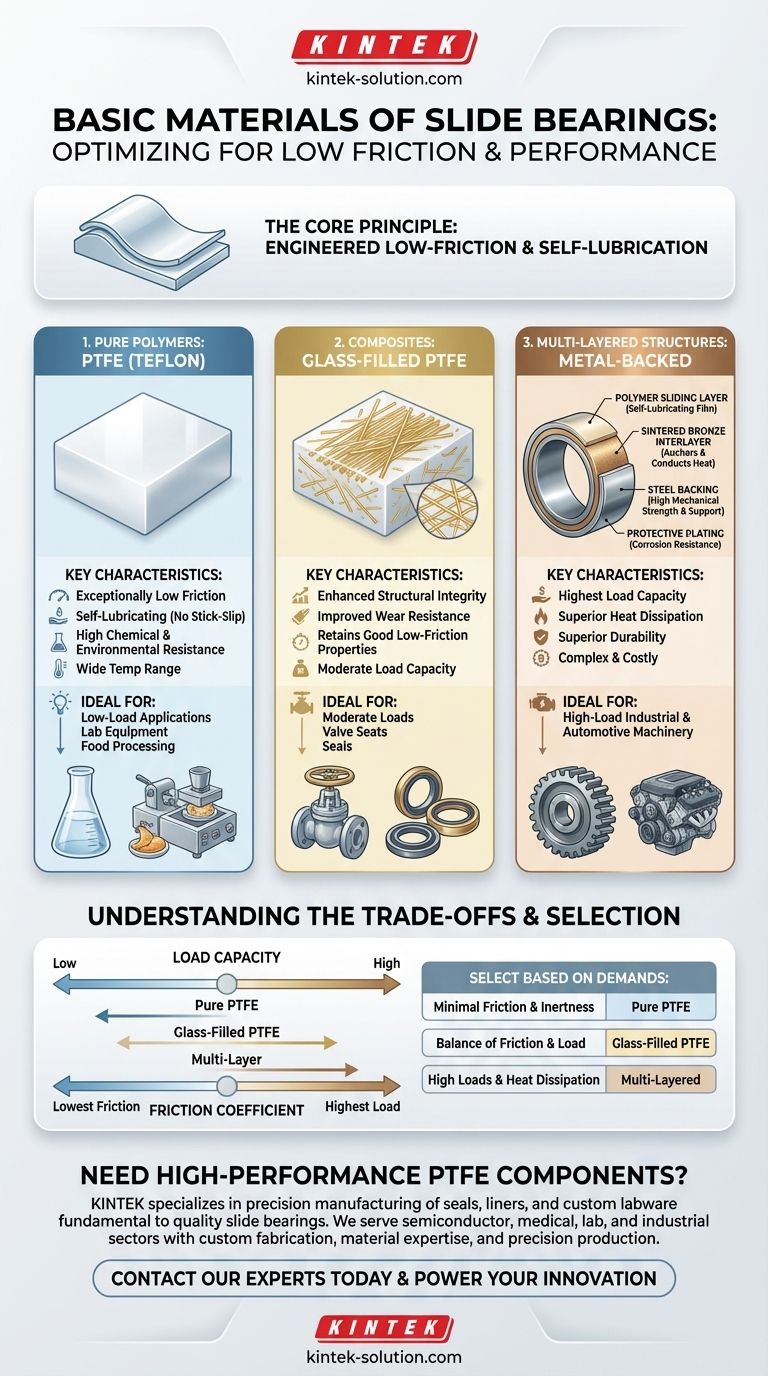

At their core, slide bearings are engineered from a select group of low-friction materials. The most common options include pure polymers like PTFE (Teflon), composites such as glass-fiber-reinforced PTFE, and advanced multi-layered structures that combine polymers with a sintered bronze interlayer and a steel backing. Each material is chosen for a specific set of performance characteristics.

The fundamental principle behind slide bearing materials is to achieve a low-friction, self-lubricating surface capable of withstanding specific loads and environmental conditions. The choice between a simple polymer and a complex metal-backed composite depends entirely on the application's demands for strength, heat dissipation, and durability.

The Role of Polymers: PTFE (Teflon)

Polytetrafluoroethylene, or PTFE, is a foundational material in slide bearing technology due to its unique molecular properties. It is easily identified by its characteristic white color.

Exceptionally Low Friction

PTFE has one of the lowest coefficients of friction of any known solid material. This creates an incredibly slick surface that minimizes resistance to movement.

Self-Lubricating Properties

The material's properties allow it to function without external lubricants. This is critical for preventing "stick-slip" action, ensuring smooth and predictable motion from a complete stop.

High Environmental Resistance

PTFE is highly resistant to weathering and a wide range of chemicals. It also functions as an excellent thermal and electrical insulator, withstanding a broad temperature range without degrading.

Enhancing Strength with Composites

While pure PTFE offers excellent low-friction properties, it lacks the mechanical strength for higher-load applications. This limitation is overcome by creating composite materials.

The Need for Reinforcement

To improve load-bearing capacity and wear resistance, PTFE is often mixed with reinforcing agents.

Glass Fiber Aggregates

A common solution is to add glass fiber aggregates to the PTFE. This composite material, often gold in color, significantly enhances the bearing's structural integrity while retaining much of the low-friction benefit.

Multi-Layered Bearings for Demanding Applications

For the most demanding industrial applications, slide bearings are constructed from multiple, specialized layers bonded together.

A Purpose-Built Structure

Each layer in these advanced bearings serves a distinct and critical function, working together to handle high loads and dissipate heat.

The Polymer Sliding Layer

The top layer is a lead-free polymer fiber mixture that makes direct contact with the moving part. This layer is designed to create a self-lubricating film during operation.

The Sintered Bronze Interlayer

Beneath the polymer is a layer of sintered bronze powder. Its porous structure helps anchor the top layer and provides excellent thermal conductivity, drawing heat away from the sliding surface.

The Steel Backing

The foundation of the bearing is a steel backing. This provides the high mechanical strength and structural support needed to handle significant static and dynamic loads.

The Protective Plating

The exterior is often finished with a copper or tin plating. This final layer serves one primary purpose: providing robust corrosion resistance for the entire bearing assembly.

Understanding the Trade-offs

Selecting the right material is a matter of balancing competing requirements. No single material is perfect for every situation.

Pure PTFE: Simplicity vs. Strength

Pure PTFE offers the lowest friction and best chemical resistance. However, it has limited load capacity and can deform under sustained pressure.

Glass-Filled PTFE: A Balanced Approach

This composite improves strength and wear resistance, making it suitable for moderate loads. The trade-off is a slightly higher coefficient of friction compared to its pure counterpart.

Metal-Backed Composites: Durability vs. Complexity

These bearings provide the highest load capacity and superior heat dissipation. They are more complex and costly, and their performance is dependent on the integrity of all bonded layers.

Selecting the Right Material for Your Application

Your final choice should be dictated by the specific demands of your project.

- If your primary focus is minimal friction and chemical inertness: Pure PTFE is the ideal choice, especially in low-load environments like laboratory equipment or food processing.

- If you need a balance of low friction and moderate load capacity: A glass-fiber-reinforced PTFE composite provides the necessary structural integrity for applications like valve seats or seals.

- If your application involves high loads and requires heat dissipation: A multi-layered, metal-backed bearing is necessary for its superior mechanical strength and thermal conductivity, common in automotive or industrial machinery.

Ultimately, understanding these material properties empowers you to select a slide bearing that is not just a component, but a solution tailored to your specific engineering challenge.

Summary Table:

| Material Type | Key Characteristics | Ideal For |

|---|---|---|

| Pure PTFE (Teflon) | Lowest friction, self-lubricating, high chemical resistance | Low-load applications, lab equipment, food processing |

| Glass-Filled PTFE Composite | Enhanced strength & wear resistance, good low-friction properties | Moderate loads, valve seats, seals |

| Multi-Layer (Polymer/Bronze/Steel) | Highest load capacity, excellent heat dissipation, superior durability | High-load industrial & automotive machinery |

Need High-Performance PTFE Components for Your Bearings?

Selecting the right slide bearing material is critical for your application's performance and longevity. KINTEK specializes in the precision manufacturing of PTFE components—including seals, liners, and custom labware—that are fundamental to high-quality slide bearings.

We serve the semiconductor, medical, laboratory, and industrial sectors, offering:

- Custom Fabrication: From prototypes to high-volume orders.

- Material Expertise: Ensuring optimal performance for low friction, strength, and environmental resistance.

- Precision Production: Guaranteeing the quality and reliability your designs demand.

Let us provide the PTFE solution that powers your innovation. Contact our experts today to discuss your project requirements!

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Customizable PTFE Rods for Advanced Industrial Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

People Also Ask

- What are the future considerations for machining Teflon? Mastering Material Challenges with Smart Tech

- What industries use PTFE machined parts and for what applications? Critical Components for Demanding Environments

- Why is CNC machining preferred for Teflon parts over other methods? Unlock Precision & Complex Designs

- What are the key advantages of PTFE? Unmatched Performance for Extreme Environments

- Why is PTFE rod suitable for automotive applications? Boost Vehicle Performance & Durability