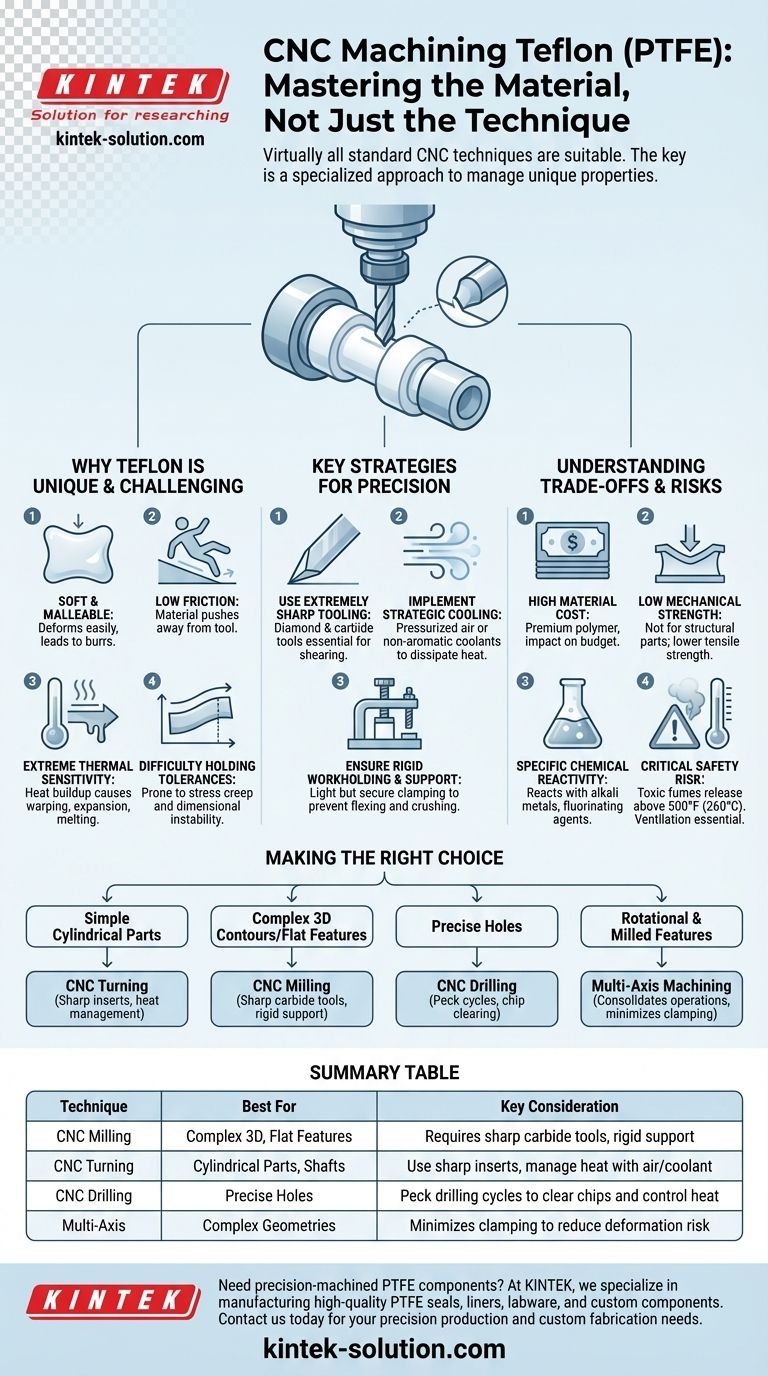

Virtually all standard CNC machining techniques are suitable for Teflon (PTFE), including CNC milling, turning, drilling, and multi-axis machining. The critical factor is not the technique itself, but the specialized approach required to manage Teflon's unique properties like its softness, low friction, and extreme sensitivity to heat.

The challenge of machining Teflon is not in choosing a technique, but in mastering the execution. Success depends entirely on adapting tooling, cooling, and workholding strategies to counteract the material's tendency to deform, melt, and resist a clean cut.

Why Teflon Demands a Specialized Machining Approach

Machining Teflon is fundamentally different from working with metals or even other polymers. Its distinct characteristics present a unique set of challenges that must be addressed to achieve precision and avoid part failure.

The Challenge of Softness and Malleability

Teflon is exceptionally soft, which means it can easily deform or compress under the pressure of a cutting tool or clamping force. This can lead to dimensional inaccuracies, tool chatter, and significant burr formation, which is difficult to remove cleanly.

The Problem with a Low Friction Surface

The material's famously low coefficient of friction means it has a tendency to slide or push away from a cutting tool rather than being sheared cleanly. This requires exceptionally sharp tooling to initiate and maintain a proper cut.

Managing Extreme Thermal Sensitivity

Teflon has a high thermal expansion coefficient and low thermal conductivity. This means heat generated during cutting stays concentrated at the tool tip, which can cause the material to warp, expand, or even melt, making it impossible to hold tight tolerances.

Critically, if Teflon is heated above 500°F (260°C), it begins to decompose and release highly toxic fumes, creating a significant health and safety hazard.

The Difficulty of Holding Tolerances

Beyond immediate heat expansion, Teflon is also prone to stress creep. This means that even after machining, the material can slowly change shape over time as internal stresses relax, compromising long-term dimensional stability.

Key Strategies for Precision Teflon Machining

Overcoming the challenges of machining PTFE requires a meticulous and deliberate strategy focused on sharp tools, temperature control, and rigid support.

Use Extremely Sharp Tooling

The single most important factor is the sharpness of the cutting tool. Tools must be able to slice the material cleanly without any pushing or rubbing.

Diamond and carbide tools are highly recommended. While they are hard, their primary benefit here is their ability to be honed to and maintain a razor-sharp edge, which is essential for shearing Teflon effectively.

Implement Strategic Cooling

Heat management is paramount. While flood coolants are not always necessary, some form of cooling is crucial to prevent heat buildup at the tool.

Effective options include pressurized air to clear chips and provide convective cooling, misting systems, or a non-aromatic, water-soluble coolant. The goal is to dissipate heat rapidly before it can deform the material.

Ensure Rigid Workholding and Support

Securing a Teflon workpiece is a delicate balance. Clamping pressure must be sufficient to prevent movement but light enough to avoid crushing or deforming the soft material.

Specialized fixtures and fully supporting the material beneath the cutting area are often required to prevent it from flexing away from the tool.

Understanding the Trade-offs and Limitations

While an excellent material for many applications, it's important to recognize Teflon's inherent limitations before committing to it for a machined part.

High Material Cost

PTFE is a premium polymer and is significantly more expensive than many common plastics, which can impact the budget for larger parts or production runs.

Low Mechanical Strength

Teflon is not a structural material. It has a lower tensile strength than other engineering plastics like nylon and is susceptible to creep under load.

Specific Chemical Reactivity

Though famously inert, Teflon can react violently with alkali metals and some highly reactive fluorinating agents.

The Critical Safety Risk

The production of toxic gas at elevated temperatures cannot be overstated. Proper ventilation and temperature control are not just best practices; they are essential safety requirements.

Making the Right Choice for Your Goal

The best CNC technique is the one that most efficiently creates your desired geometry while adhering to the principles of machining Teflon.

- If your primary focus is simple cylindrical parts: CNC turning with extremely sharp inserts is the most direct and effective method.

- If your primary focus is complex 3D contours or flat features: CNC milling, particularly 3- or 5-axis machining, offers the necessary geometric freedom.

- If your primary focus is creating precise holes: CNC drilling is effective, but requires sharp drill bits and careful attention to pecking cycles to clear chips and manage heat.

- If your primary focus is parts with both rotational and milled features: CNC turn-mill centers are ideal for consolidating operations, minimizing clamping, and improving overall accuracy.

Ultimately, successful Teflon machining is less about the machine and more about the methodology; a deep understanding of the material's behavior is your greatest asset.

Summary Table:

| Technique | Best For | Key Consideration |

|---|---|---|

| CNC Milling | Complex 3D contours, flat features | Requires sharp carbide tools, rigid support |

| CNC Turning | Cylindrical parts, shafts | Use sharp inserts, manage heat with air/coolant |

| CNC Drilling | Precise holes | Peck drilling cycles to clear chips and control heat |

| Multi-Axis Machining | Complex geometries in one setup | Minimizes clamping to reduce deformation risk |

Need precision-machined PTFE components?

At KINTEK, we specialize in manufacturing high-quality PTFE seals, liners, labware, and custom components for the semiconductor, medical, laboratory, and industrial sectors. Our expertise in adapting CNC techniques for Teflon's unique properties ensures your parts meet exact specifications, from prototypes to high-volume orders.

Contact us today to discuss your project and benefit from our precision production and custom fabrication capabilities.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

People Also Ask

- What chemical processing applications involve PTFE-machined parts? Essential Components for Corrosive & High-Purity Systems

- What industrial benefits do PTFE-machined parts offer? Achieve Peak Performance in Demanding Applications

- What factors should be considered when choosing between Nylon and PTFE? Select the Right Material for Your Application

- What fabrication services are available for PTFE? Shearing, Stamping, Laser Cutting, Molding & Machining

- What are the main applications of PTFE type Teflon? Unlock Its Versatility for Your Industry