In short, PTFE bellows and diaphragms are predominantly used in industries where process purity and resistance to harsh conditions are non-negotiable. Key sectors include semiconductor manufacturing, chemical processing, medical and pharmaceutical, and aerospace due to PTFE's unique combination of chemical inertness, high purity, thermal stability, and biocompatibility.

The decision to use a PTFE bellow or diaphragm is almost always driven by a need to protect a sensitive process from contamination or to protect the component itself from a corrosive environment. Its selection signals that performance and reliability under extreme conditions are the primary engineering concerns.

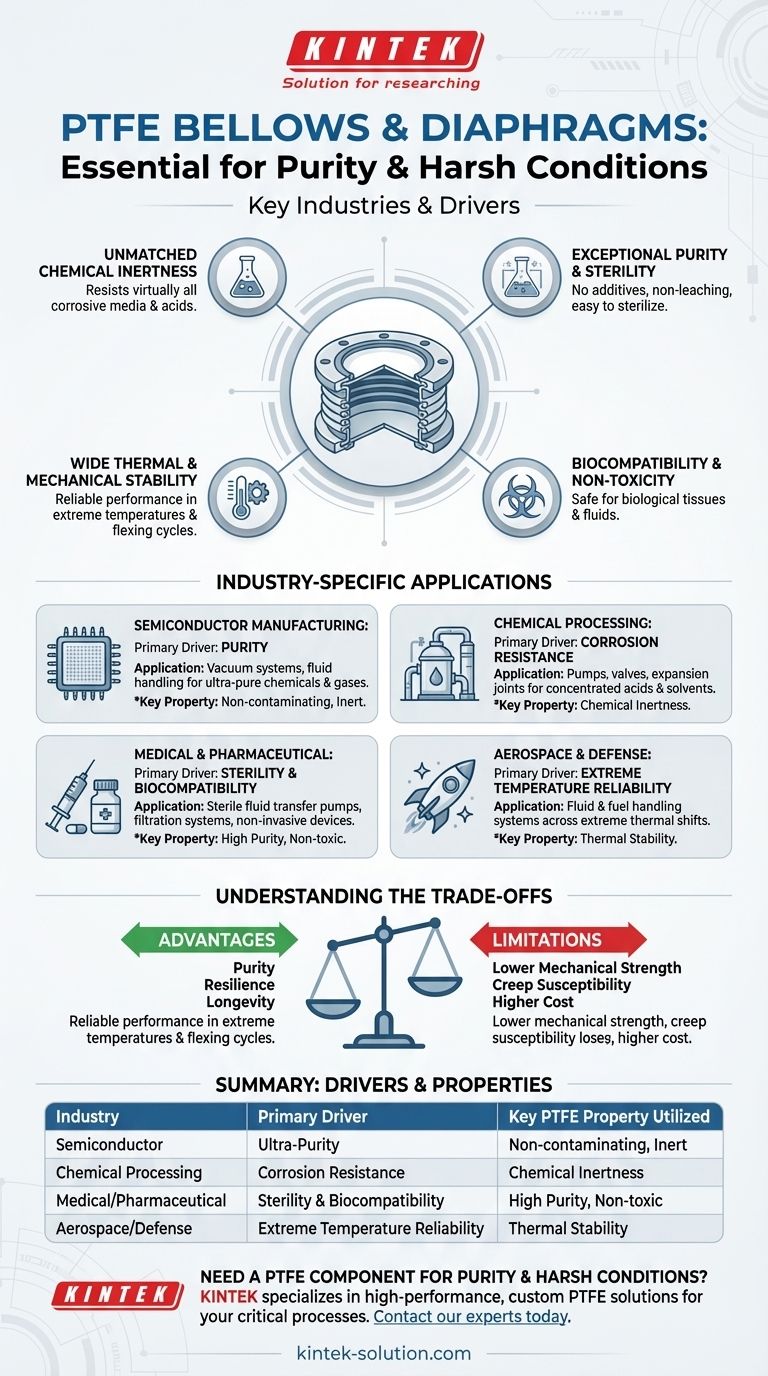

The Core Properties Driving Adoption

To understand why these specific industries rely on PTFE, we must first look at the material's fundamental characteristics. These components are not chosen for general-purpose applications; they are specified when conventional materials would fail.

### Unmatched Chemical Inertness

PTFE is virtually inert and does not react with the vast majority of industrial chemicals, acids, and bases. This makes it the default choice for components that will be in direct contact with highly corrosive or aggressive media.

This property is critical in pumps, valves, and reactors where material degradation would lead to catastrophic failure and process contamination.

### Exceptional Purity and Sterility

High-purity grades of PTFE contain no additives, plasticizers, or leachable components that could contaminate a process fluid. This is an absolute requirement in industries where even trace amounts of impurities can ruin an entire batch of product.

Furthermore, its smooth, non-porous surface is easy to clean and sterilize, preventing bacterial growth and cross-contamination.

### Wide Thermal and Mechanical Stability

PTFE maintains its properties across a very wide temperature range, performing reliably in both cryogenic conditions and high-temperature environments.

While not as rigid as metal, its flexibility and durability make it ideal for the repeated flexing motions required of bellows and diaphragms, ensuring a long operational life in demanding cycles.

### Biocompatibility and Non-Toxicity

PTFE is non-toxic and biocompatible, meaning it does not cause adverse reactions when in contact with biological tissues or fluids. This has made it a standard material for medical implants and equipment used in pharmaceutical manufacturing.

Industry-Specific Applications Breakdown

Each industry leverages a specific combination of PTFE's properties to solve its unique challenges.

### Semiconductor Manufacturing

In this industry, the primary driver is purity. Bellows are used in vacuum systems and fluid handling equipment to isolate and transport ultra-pure chemicals and gases. Any contamination from the component would result in defective microchips, making PTFE's inertness and non-leaching nature essential.

### Chemical Processing

Here, the defining requirement is chemical resistance. PTFE bellows and diaphragms are used in pumps, valves, and expansion joints that handle substances like concentrated acids and solvents. They provide a flexible seal that can withstand chemical attack that would destroy metals and other plastics.

### Medical and Pharmaceutical

The focus in this sector is on biocompatibility and sterility. Diaphragms are used in pumps for sterile fluid transfer and filtration systems, ensuring the product remains pure. Bellows can be used to protect sterile mechanisms or as components in non-invasive medical devices.

### Aerospace and Defense

For aerospace applications, thermal and mechanical stability are key. PTFE components are used in fluid and fuel handling systems that must perform reliably across extreme temperature shifts, from ground level to high altitude. Their reliability in critical sealing applications is paramount.

### Precision Instrumentation

In scientific and analytical instruments, PTFE components are used for media isolation. A PTFE bellow can isolate a sensitive sensor from a corrosive fluid while accurately transmitting pressure, ensuring the purity of the sample and the integrity of the measurement.

Understanding the Trade-offs

While PTFE offers exceptional performance, it is critical to understand its limitations to make an informed decision. It is an engineered solution for specific problems, not a universal one.

### Mechanical Limitations

Compared to metal components, PTFE has lower tensile strength and rigidity. It is not suitable for high-pressure applications without reinforcement, as it can deform under significant mechanical stress.

### Susceptibility to Creep

Under a constant, sustained load (especially at elevated temperatures), PTFE can slowly deform over time. This phenomenon, known as "creep," must be factored into the design of any component under constant mechanical pressure.

### Higher Material Cost

PTFE is a premium performance polymer. Its initial cost is higher than that of many common elastomers or plastics. The investment is justified by its long service life and the prevention of costly failures in critical applications.

Making the Right Choice for Your Application

The suitability of a PTFE bellow or diaphragm depends entirely on your primary engineering goal.

- If your primary focus is preventing contamination and ensuring process purity: PTFE is an industry-standard choice, particularly in semiconductor, medical, and pharmaceutical applications.

- If your primary focus is handling highly corrosive or aggressive media: PTFE's chemical inertness is its defining advantage and often makes it the only viable option.

- If your primary focus is high mechanical strength and pressure resistance: You should evaluate whether a pure PTFE component is sufficient or if a reinforced design or an alternative material like metal is more appropriate.

Ultimately, choosing PTFE is a strategic decision to prioritize purity and chemical resilience above all other concerns.

Summary Table:

| Industry | Primary Driver | Key PTFE Property Utilized |

|---|---|---|

| Semiconductor | Ultra-Purity | Non-contaminating, Inert |

| Chemical Processing | Corrosion Resistance | Chemical Inertness |

| Medical/Pharmaceutical | Sterility & Biocompatibility | High Purity, Non-toxic |

| Aerospace/Defense | Extreme Temperature Reliability | Thermal Stability |

Need a PTFE component that guarantees purity and withstands harsh conditions?

At KINTEK, we specialize in manufacturing high-performance, custom PTFE components—including seals, bellows, liners, and labware—for the semiconductor, medical, laboratory, and industrial sectors. Our precision production and custom fabrication services, from prototypes to high-volume orders, ensure you get a reliable solution tailored to your exact needs.

Contact our experts today to discuss how our PTFE components can protect your critical processes.

Visual Guide

Related Products

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Bottles for Diverse Industrial Applications

People Also Ask

- What temperature range can Teflon (PTFE) balls withstand? -200°C to +260°C Performance Guide

- What are the overall advantages of using PTFE balls in fluid management systems? Enhance Reliability & Efficiency

- What are the advantages of PTFE balls over metals or alloys? Superior Chemical & Friction Resistance

- What are the available grades of PTFE balls? Choose the Right Grade for Your Application

- How do the chemical properties of PTFE balls influence their performance? Unmatched Durability in Harsh Environments