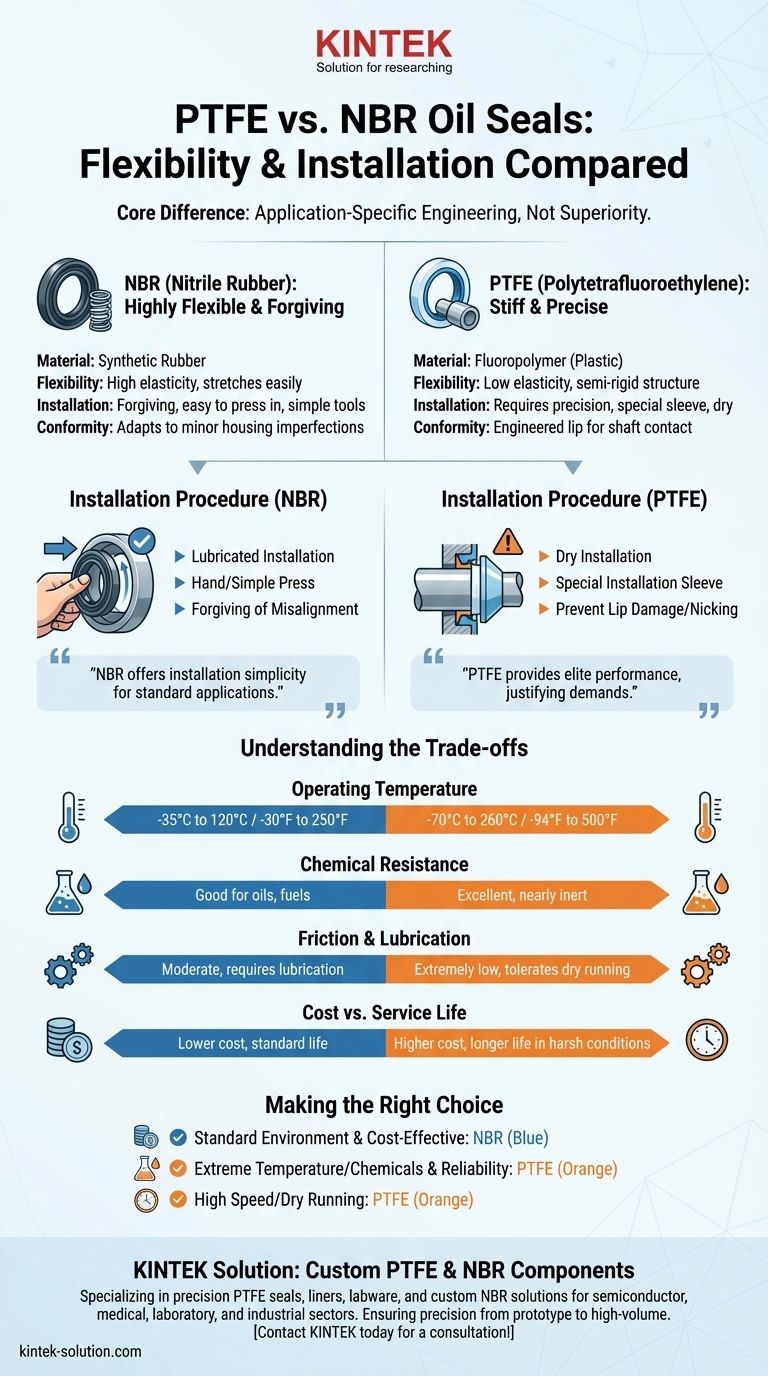

In terms of installation and flexibility, Nitrile Butadiene Rubber (NBR) oil seals are highly flexible and forgiving, making them easy to install. In stark contrast, Polytetrafluoroethylene (PTFE) oil seals are characterized by their stiffness, which demands a precise and careful installation process to prevent damage and ensure a proper seal.

The core difference is not a matter of one being superior, but of application-specific engineering. NBR offers installation simplicity for standard applications, while PTFE provides elite performance in extreme conditions, justifying its more demanding installation requirements.

The Fundamental Difference in Material Properties

The contrast in installation experience stems directly from the inherent nature of each material. They are fundamentally different compounds designed for different operational challenges.

NBR (Nitrile Rubber): The Flexible Standard

NBR, a synthetic rubber, is defined by its elasticity. This rubber-like pliability makes it easy to handle and press into a housing, often with minimal tooling.

Its flexibility allows it to easily stretch over a shaft during installation and readily conform to minor imperfections in the housing bore.

PTFE (Polytetrafluoroethylene): The Rigid Performer

PTFE is a fluoropolymer—a type of plastic, not a rubber. This gives the seal a semi-rigid or stiff structure that has very little elasticity.

This rigidity is key to its performance at high pressures and temperatures but means it cannot be installed with the same brute force or forgiveness as an NBR seal. Bending or improperly forcing a PTFE seal will permanently damage it.

Clarifying "Flexibility": Installation vs. Sealing Lip

While the body of a PTFE seal is stiff, its sealing lip is engineered with a specific type of flexibility. It is designed to conform precisely to the shaft's surface.

This is different from NBR's material elasticity. PTFE's design ensures a tight, reliable seal on worn or slightly irregular shafts, but this engineered conformity does not make the overall seal pliable or easy to handle during installation.

Why Installation Demands Are So Different

The material properties dictate entirely different installation procedures. Mistaking one for the other is a common cause of premature seal failure.

The Forgiving Nature of NBR Installation

An NBR seal is lubricated and can typically be pressed into place by hand or with a simple flat press tool. Its elasticity is forgiving of minor misalignments.

The primary goal is to seat it evenly in its housing without twisting the seal.

The Precision Mandate of PTFE Installation

Installing a PTFE seal is a more technical process. The seal must be installed dry, as the sealing lip needs to transfer a thin layer of PTFE material to the shaft to create its unique low-friction sealing surface.

Because the lip is fragile and the body is stiff, a special installation sleeve or cone is required. This tool guides the seal onto the shaft, preventing the lip from being nicked, rolled, or damaged in any way.

Understanding the Trade-offs

Choosing between NBR and PTFE goes far beyond installation. The difficulty of installing a PTFE seal is a trade-off for its superior performance in demanding environments.

Operating Temperature

NBR performs well in moderate temperature ranges, typically from -35°C to 120°C (-30°F to 250°F). PTFE excels in extreme conditions, handling ranges from -70°C to 260°C (-94°F to 500°F).

Chemical Resistance

NBR is suitable for standard mineral oils, hydraulic fluids, and fuels. PTFE is nearly chemically inert, making it essential for applications involving aggressive solvents, acids, or other harsh chemicals.

Friction and Lubrication

NBR seals require lubrication to function and have moderate friction. PTFE seals are known for their extremely low friction and can even tolerate periods of dry running, which would quickly destroy an NBR seal.

Cost vs. Service Life

NBR seals are significantly more affordable and widely available, making them the cost-effective choice for countless standard applications.

PTFE seals have a higher initial cost, but their exceptional durability and resistance to heat and chemicals provide a much longer service life in harsh conditions, preventing costly downtime.

Making the Right Choice for Your Application

Your final decision must be guided by the operational demands of the machinery, not just the initial installation convenience.

- If your primary focus is cost-effectiveness and simple installation in a standard environment: NBR is the clear and correct choice.

- If your primary focus is reliability in extreme temperatures or with aggressive chemicals: The precision installation of a PTFE seal is a necessary investment for long-term performance.

- If your application involves high shaft speeds or the potential for dry running: PTFE's unique low-friction properties are essential to prevent premature failure.

Ultimately, matching the seal's capabilities to the application's demands is the only way to ensure reliable, long-term performance.

Summary Table:

| Feature | NBR (Nitrile Rubber) | PTFE (Polytetrafluoroethylene) |

|---|---|---|

| Material Type | Synthetic Rubber | Fluoropolymer (Plastic) |

| Flexibility & Installation | Highly flexible, forgiving, easy to install | Stiff, requires precise installation with tools |

| Operating Temperature | -35°C to 120°C (-30°F to 250°F) | -70°C to 260°C (-94°F to 500°F) |

| Chemical Resistance | Good for oils, fuels, hydraulic fluids | Excellent, nearly inert to harsh chemicals & acids |

| Friction/Lubrication | Moderate friction, requires lubrication | Extremely low friction, tolerates dry running |

| Best For | Cost-effective, standard environments | Extreme temperatures, harsh chemicals, high speeds |

Need High-Performance PTFE Seals or Reliable NBR Components?

KINTEK specializes in manufacturing precision PTFE components—including seals, liners, and labware—for the semiconductor, medical, laboratory, and industrial sectors. We also provide custom NBR solutions.

We understand that the right seal is critical to your system's performance and longevity. Whether you need the extreme durability of PTFE for harsh conditions or the cost-effectiveness of NBR for standard applications, our team ensures precision production from prototypes to high-volume orders.

Let us provide the perfect sealing solution for your specific needs. Contact KINTEB today for a consultation!

Visual Guide

Related Products

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Bottles for Diverse Industrial Applications

People Also Ask

- What are the benefits of using PTFE seals? Unmatched Chemical & Temperature Resistance

- What are the key advantages of PTFE rotary seals over traditional rubber seals? Superior Performance in Extreme Conditions

- What are the two temperature extremes discussed for PTFE seals? Maximize Performance from Cryogenic to High-Heat

- What are the key properties of PTFE that make it suitable for sealing applications? | High-Performance Seals for Extreme Conditions

- What are the benefits of PTFE seals in terms of prototyping and production? Accelerate R&D and Ensure Elite Performance