In short, Teflon is difficult to machine to tight tolerances because its dimensions are inherently unstable. The material expands and contracts dramatically with even minor temperature changes, and it slowly deforms over time under stress—a property known as creep. These two factors mean a precisely machined part can change size both during the cutting process and long after it has been finished.

The core challenge is not the cutting itself, but the material's response to temperature and pressure. Unlike metals, which are rigid and stable, Teflon is a "living" material that moves, making it a moving target for achieving and holding precise dimensions.

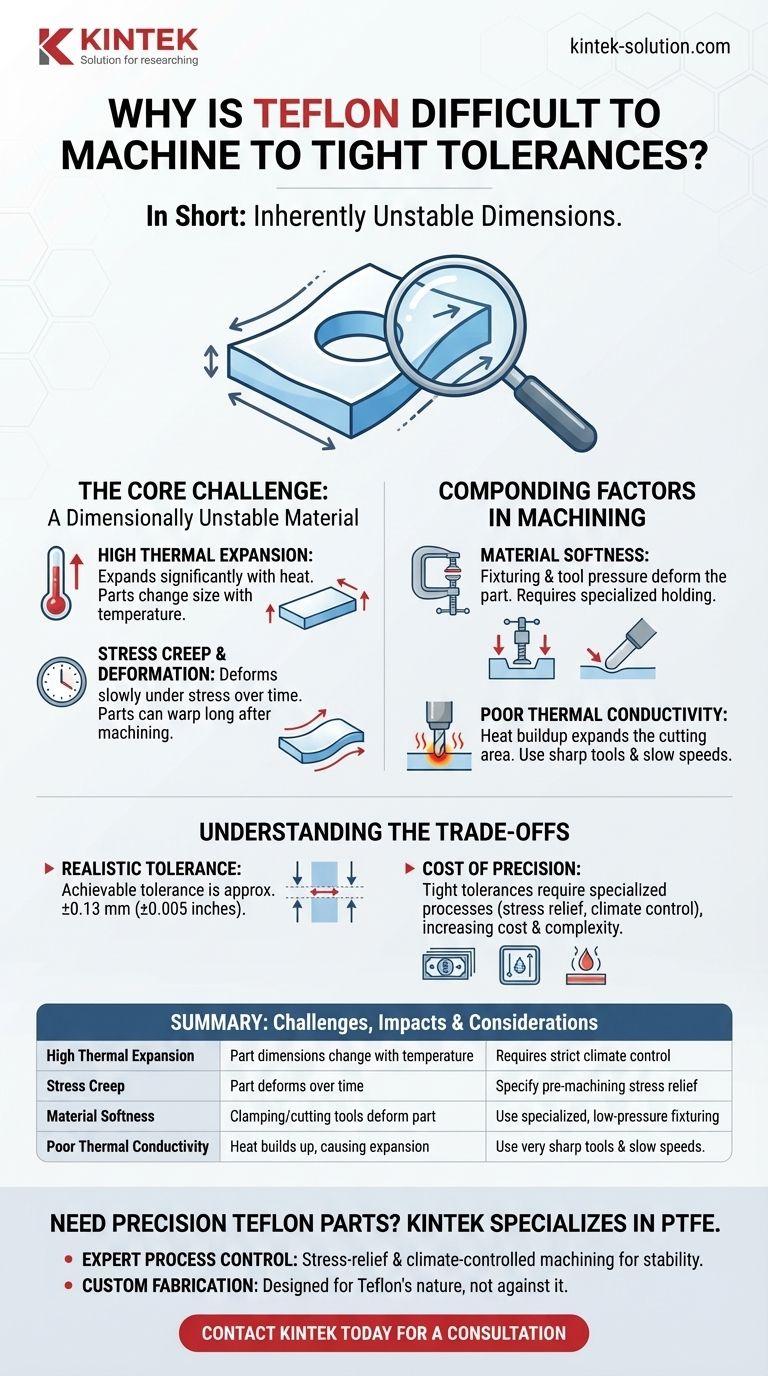

The Core Challenge: A Dimensionally Unstable Material

To understand the difficulty of machining Teflon, we must first look at its fundamental physical properties. The problems begin before a cutting tool ever touches the material.

High Thermal Expansion

Teflon (PTFE) has an extremely high coefficient of thermal expansion. This means it expands when heated and contracts when cooled to a much greater degree than metals like aluminum or steel.

The heat generated by the machining process itself—or even just a change in room temperature—is enough to cause significant dimensional changes. A part measured at one temperature may be out of tolerance at another, making consistent precision nearly impossible without strict environmental controls.

Stress Creep and Deformation

Teflon is susceptible to stress creep, which is the tendency of a solid material to move slowly or deform permanently under the influence of persistent stress.

Internal stresses are introduced during manufacturing and machining. Over time, the material relaxes, causing the part to warp, bend, or change dimensionally. This means a part can be perfectly in-spec right off the machine but fall out of tolerance days or weeks later.

Compounding Factors in the Machining Process

The inherent instability of Teflon is made worse by the physical act of machining, which introduces additional heat and pressure.

Material Softness

Teflon is a very soft material. This creates two primary problems:

- Fixturing Pressure: The clamping force required to hold the material for machining can easily compress or deform it, leading to inaccurate cuts.

- Tool Pressure: The cutting tool itself can push the material away rather than shearing it cleanly, resulting in poor surface finishes and dimensional errors. This softness also makes the material prone to burrs.

Poor Thermal Conductivity

Teflon is an excellent thermal insulator. While this is a useful property in many applications, it creates significant problems during machining.

Heat generated at the cutting edge does not dissipate quickly through the material. This localized heat buildup causes the area being cut to expand, throwing off the accuracy of the operation in real-time.

Unique Tooling Requirements

Because Teflon is soft and gummy, it requires exceptionally sharp cutting tools, typically made of carbide. A dull tool will plow through the material instead of cutting it, increasing heat, deformation, and the likelihood of a poor surface finish.

Understanding the Trade-offs

These challenges have direct, practical consequences for design, cost, and performance. Ignoring them leads to failed parts and budget overruns.

The Reality of Tolerances

For most general applications, an achievable tolerance for machined Teflon is around ±0.13 mm (±0.005 inches).

Attempting to hold tolerances tighter than this is possible, but it requires specialized techniques that dramatically increase complexity and cost.

The Cost of Precision

Achieving high precision with Teflon is not a standard operation. It requires a controlled process that may include:

- Stress-Relieving: Annealing the raw material before machining to reduce internal stresses.

- Climate Control: Machining in a temperature-controlled environment.

- Specialized Fixturing: Custom jigs that support the part without deforming it.

- Slower Speeds: Using very low cutting speeds and feed rates to minimize heat generation.

Post-Machining Instability

The most critical trade-off to consider is the risk of a part changing size after inspection. Due to stress creep, a component may be dimensionally perfect when it leaves the shop but fail in its application weeks later as the material settles.

How to Approach Teflon Machining for Your Project

Your strategy must be dictated by your application's specific requirements. Success depends on designing for the material's properties from the start.

- If your primary focus is general function or prototyping: Design with looser tolerances in mind and leverage Teflon's natural flexibility.

- If your primary focus is holding a single critical dimension: Specify pre-machining stress relief (annealing) for the material and ensure your manufacturing partner uses a climate-controlled process.

- If your primary focus is complex geometry with tight tolerances: Be prepared for significantly higher costs, work only with machine shops that specialize in performance plastics, and discuss post-machining stability.

Ultimately, mastering Teflon machining is less about forcing the material to be precise and more about understanding and accommodating its inherent nature.

Summary Table:

| Challenge | Impact on Machining | Key Consideration |

|---|---|---|

| High Thermal Expansion | Part dimensions change with temperature. | Requires strict climate control during machining. |

| Stress Creep | Part deforms over time after machining. | Specify pre-machining stress relief (annealing). |

| Material Softness | Clamping and cutting tools can deform the part. | Use specialized, low-pressure fixturing. |

| Poor Thermal Conductivity | Heat builds up during cutting, causing expansion. | Use very sharp tools and slow cutting speeds. |

Need Precision Teflon Parts That Hold Their Tolerances?

Machining Teflon (PTFE) to tight specifications requires a deep understanding of its unique properties. KINTEK specializes in manufacturing high-performance PTFE components for the semiconductor, medical, laboratory, and industrial sectors. We overcome material instability through:

- Expert Process Control: Our techniques include material stress-relief and climate-controlled machining to ensure dimensional stability.

- Custom Fabrication: From prototypes to high-volume orders, we design processes that work with Teflon's nature, not against it.

Let us deliver the precision and reliability your application demands.

Contact KINTEK today for a consultation

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Customizable PTFE Rods for Advanced Industrial Applications

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Custom PTFE Square Trays for Industrial and Laboratory Use

People Also Ask

- What design considerations are important for custom PTFE parts? Design for Performance & Reliability

- What factors should be considered when choosing between Nylon and PTFE? Select the Right Material for Your Application

- What finishing techniques are effective for machined Teflon parts? Achieve Functional Performance and Dimensional Stability

- What industrial benefits do PTFE-machined parts offer? Achieve Peak Performance in Demanding Applications

- What are the unique properties of PTFE? The 3 Pillars Driving Demand for High-Performance Parts