At its core, Polytetrafluoroethylene (PTFE) coating is a high-performance fluoropolymer known for an exceptional combination of properties that make it invaluable across industries. Its primary benefits include an extremely low coefficient of friction for non-stick surfaces, robust chemical inertness, high-temperature resistance, and excellent electrical insulation. These attributes solve critical engineering challenges where other materials would fail.

The true value of PTFE isn't a single feature like being "non-stick," but its unique ability to deliver multiple high-performance characteristics simultaneously. This synergy allows it to enhance efficiency, safety, and reliability in the most demanding operational environments.

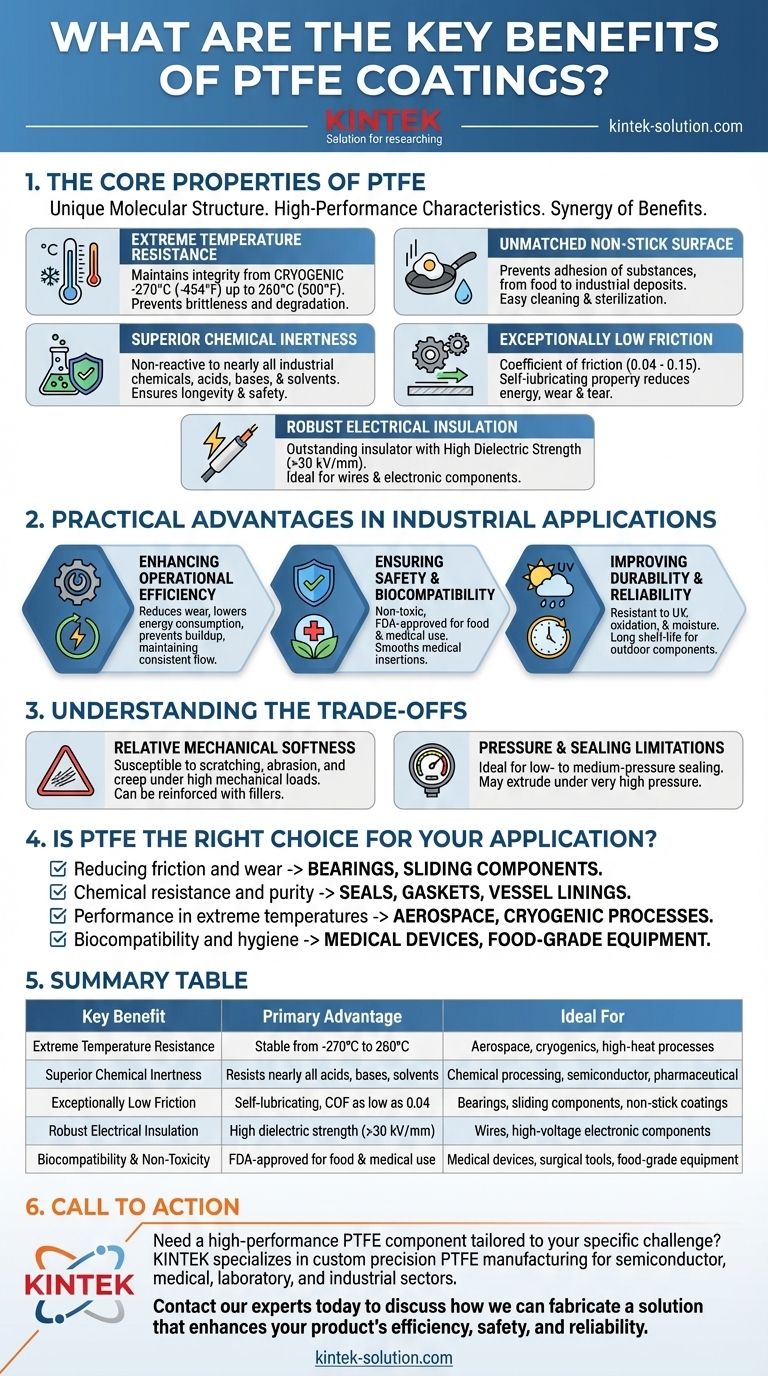

The Core Properties of PTFE

The benefits of PTFE stem from its unique molecular structure, which gives rise to a set of highly desirable material properties. Understanding these fundamentals is key to appreciating its wide-ranging applications.

### Extreme Temperature Resistance

PTFE maintains its integrity and performance across an exceptionally wide thermal range. It can withstand continuous service temperatures from cryogenic lows of -270°C (-454°F) up to 260°C (500°F).

This stability prevents the material from becoming brittle at low temperatures or degrading under high heat, ensuring reliable performance in extreme conditions.

### Unmatched Non-Stick Surface

PTFE coatings provide one of the world's most effective non-stick, or release, surfaces. This property prevents other substances, from sticky food products to industrial deposits, from adhering.

This is critical in applications requiring hygiene and easy cleaning, such as medical instruments and food processing equipment, as it simplifies sterilization and maintenance.

### Superior Chemical Inertness

PTFE is chemically inert and non-reactive to nearly all industrial chemicals, acids, bases, and solvents. This makes it an ideal material for seals, linings, and components that handle corrosive substances.

Its resistance to chemical attack ensures the longevity and safety of equipment, preventing leaks and material degradation over time.

### Exceptionally Low Friction

With a coefficient of friction between 0.04 and 0.15, PTFE is one of the slipperiest solid materials known. This inherent lubricity is often referred to as a "self-lubricating" property.

This dramatically reduces the energy required for moving parts to operate, minimizes wear and tear on components, and prevents the buildup of materials that could obstruct flow in pipes or joints.

### Robust Electrical Insulation

PTFE is an outstanding electrical insulator with a very high dielectric strength, often exceeding 30 kV/mm. It does not conduct electricity, making it an ideal coating for wires and electronic components.

This property is essential for preventing short circuits and ensuring the safety and reliability of electrical systems, especially in high-voltage applications.

Practical Advantages in Industrial Applications

These fundamental properties translate directly into tangible benefits that improve performance, efficiency, and safety in real-world scenarios.

### Enhancing Operational Efficiency

The low-friction surface of PTFE reduces wear on mechanical parts and lowers the energy needed to operate machinery. This leads to longer component life and reduced power consumption.

In fluid systems, its smooth, non-stick surface prevents scaling and deposit buildup, maintaining consistent flow rates and minimizing the need for costly maintenance and downtime.

### Ensuring Safety and Biocompatibility

PTFE is non-toxic and has been approved by the FDA for use in food contact and medical applications. Its inert nature means it won't react with biological tissues or fluids.

In medical devices like catheters and guidewires, PTFE coatings reduce friction for smoother insertion, minimizing patient discomfort and the risk of tissue damage.

### Improving Durability and Reliability

PTFE is highly resistant to environmental factors, including UV radiation, oxidation, and moisture. This gives it a long shelf-life and ensures it does not become brittle or degrade when exposed to the elements.

This durability makes PTFE a reliable choice for long-term sealing applications and outdoor components where other polymers might fail over time.

Understanding the Trade-offs

While its benefits are significant, it is crucial to understand the limitations of PTFE to ensure it is specified correctly for a given application.

### Relative Mechanical Softness

PTFE is a relatively soft material. While this contributes to its excellent sealing capabilities, it means it can be susceptible to scratching, abrasion, and creep under high mechanical loads.

For applications requiring high wear resistance, PTFE is often blended with fillers like glass, carbon, or graphite to improve its mechanical strength.

### Pressure and Sealing Limitations

The softness and elasticity of PTFE make it ideal for low- and medium-pressure sealing applications. It conforms well to surfaces to create a tight seal.

However, in very high-pressure systems, pure PTFE may be prone to extrusion. The design of the seal or the use of reinforced PTFE grades must be considered for such scenarios.

Is PTFE the Right Choice for Your Application?

Choosing the right material requires aligning its properties with your primary engineering goal.

- If your primary focus is reducing friction and wear: PTFE's exceptionally low coefficient of friction makes it an ideal choice for bearings, sliding components, and non-stick industrial coatings.

- If your primary focus is chemical resistance and purity: Its chemical inertness is unmatched for seals, gaskets, and vessel linings in the chemical processing, pharmaceutical, and semiconductor industries.

- If your primary focus is performance in extreme temperatures: PTFE's wide operating temperature range ensures reliability in aerospace, cryogenic, and high-heat industrial processes.

- If your primary focus is biocompatibility and hygiene: Its non-toxic, non-stick, and FDA-compliant nature is essential for medical devices, surgical tools, and food-grade equipment.

Ultimately, PTFE's unique combination of properties makes it a premier problem-solving material for engineering challenges that demand high performance under difficult conditions.

Summary Table:

| Key Benefit | Primary Advantage | Ideal For |

|---|---|---|

| Extreme Temperature Resistance | Stable from -270°C to 260°C | Aerospace, cryogenics, high-heat processes |

| Superior Chemical Inertness | Resists nearly all acids, bases, solvents | Chemical processing, semiconductor, pharmaceutical |

| Exceptionally Low Friction | Self-lubricating, coefficient of friction as low as 0.04 | Bearings, sliding components, non-stick coatings |

| Robust Electrical Insulation | High dielectric strength (>30 kV/mm) | Wires, high-voltage electronic components |

| Biocompatibility & Non-Toxicity | FDA-approved for food and medical use | Medical devices, surgical tools, food-grade equipment |

Need a high-performance PTFE component tailored to your specific challenge?

KINTEK specializes in the precision manufacturing of custom PTFE components—including seals, liners, and labware—for the semiconductor, medical, laboratory, and industrial sectors. Whether you require prototypes or high-volume orders, our expertise ensures your application benefits from PTFE's unmatched chemical resistance, temperature stability, and low friction.

Contact our experts today to discuss how we can fabricate a solution that enhances your product's efficiency, safety, and reliability.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Square Trays for Industrial and Laboratory Use

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

People Also Ask

- What chemical processing applications involve PTFE-machined parts? Essential Components for Corrosive & High-Purity Systems

- What finishing techniques are effective for machined Teflon parts? Achieve Functional Performance and Dimensional Stability

- What industrial benefits do PTFE-machined parts offer? Achieve Peak Performance in Demanding Applications

- What fabrication services are available for PTFE? Shearing, Stamping, Laser Cutting, Molding & Machining

- What challenges arise when machining PTFE (Teflon)? Overcome Softness, Heat, and Instability