For most performance-critical applications, fibrous fillers generally provide superior wear and extrusion resistance in PTFE compared to particulate fillers. They can often achieve these enhanced properties at lower fill percentages. However, the definitive "better" option is entirely dependent on the specific mechanical, thermal, and chemical demands of your application.

The choice between fibrous and particulate fillers in PTFE is not about inherent superiority, but about strategic selection. Fibrous fillers excel in dynamic, high-wear scenarios, while particulate fillers offer a balanced profile of enhanced compressive strength and general durability, often at a lower cost.

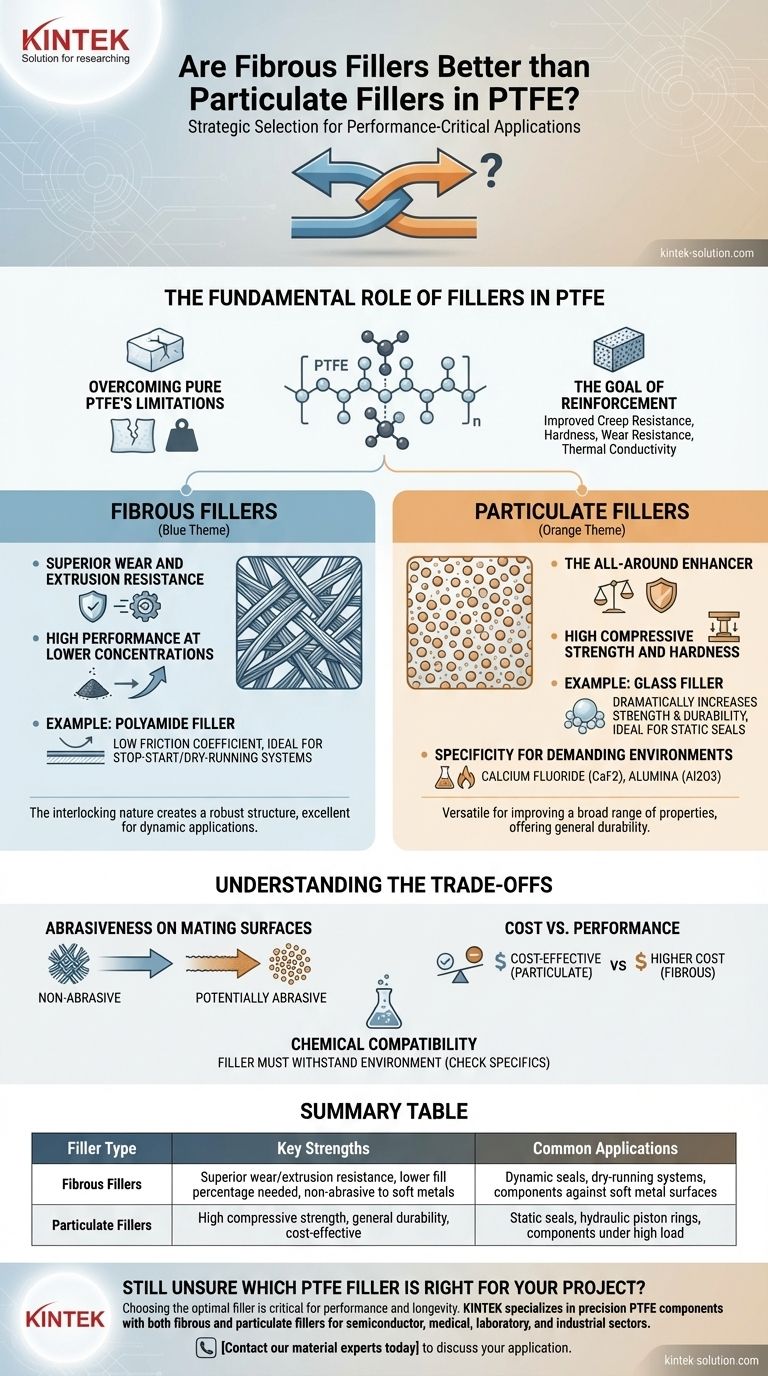

The Fundamental Role of Fillers in PTFE

Overcoming Pure PTFE's Limitations

Virgin PTFE is known for its exceptional chemical inertness and low coefficient of friction. However, it is mechanically soft and highly susceptible to creep, or cold flow, especially under heavy loads.

Fillers are introduced to create a composite material that mitigates these weaknesses. They act as a reinforcing matrix within the PTFE, significantly improving its mechanical and thermal properties.

The Goal of Reinforcement

The primary purpose of adding fillers is to enhance specific characteristics of the PTFE. This includes improving creep resistance, hardness, wear resistance, and thermal conductivity to meet the demands of an engineering application.

Analyzing Fibrous Fillers

Superior Wear and Extrusion Resistance

The key advantage of fibrous fillers is their high aspect ratio. The interlocking nature of these fibers creates a robust internal structure that provides excellent resistance to wear in dynamic applications and prevents material extrusion under high pressure.

High Performance at Lower Concentrations

Due to their structural efficiency, fibrous fillers can often achieve the desired performance enhancements with a lower percentage of the total material weight compared to particulate fillers.

Example: Polyamide Filler

Polyamide is a synthetic polymer filler that excels in applications requiring a low friction coefficient. It is particularly well-suited for use against softer counter-surfaces like stainless steel, brass, and aluminum due to its non-abrasive nature. This makes it ideal for stop-start or dry-running systems.

Understanding Particulate Fillers

The All-Around Enhancer

Particulate fillers are a versatile and common method for improving a broad range of PTFE properties, most notably compressive strength and hardness. They provide a general-purpose boost to the material's durability.

Example: Glass Filler

Glass is the most widely used filler in PTFE. It dramatically increases the material's strength and durability. Higher concentrations of glass filler directly correlate to improved compressive strength, making it a standard choice for components like hydraulic piston rings.

Specificity for Demanding Environments

Other particulate fillers are chosen for their unique properties. Materials like calcium fluoride (CaF2) or alumina (Al2O3) are selected for applications requiring specific resistance to harsh chemical or thermal environments where other fillers might fail.

Understanding the Trade-offs

Abrasiveness on Mating Surfaces

A critical factor is the filler's effect on the surface it runs against. Particulate fillers like glass can be abrasive and may cause premature wear on softer metal shafts or housings. Fibrous fillers like polyamide are often specified for their gentle interaction with such surfaces.

Cost vs. Performance

Common particulate fillers, especially glass, are typically more cost-effective than specialized fibrous fillers. For applications where the absolute highest wear resistance is not the primary driver, a glass-filled compound can offer a very effective balance of performance and price.

Chemical Compatibility

While PTFE itself is nearly universally inert, the filler material is not. The selected filler must be able to withstand the chemical environment of the application. An otherwise perfect material will fail if its reinforcing filler degrades.

Making the Right Choice for Your Application

- If your primary focus is dynamic wear resistance and extrusion prevention: A fibrous filler like polyamide is likely the superior choice, especially in dry-running or non-lubricated systems.

- If your primary focus is high compressive strength and general durability: A particulate filler like glass is a proven, cost-effective solution, particularly for static seals or components under high load.

- If your primary focus is compatibility with soft metal surfaces: A non-abrasive fibrous filler like polyamide is critical to prevent damage to mating components.

- If your primary focus is a specific chemical or thermal environment: You must select a specialized particulate filler, such as calcium fluoride or alumina, that is inert under your specific operating conditions.

Ultimately, the best filler is not defined by its form, but by its precise alignment with your specific engineering requirements.

Summary Table:

| Filler Type | Key Strengths | Common Applications |

|---|---|---|

| Fibrous Fillers | Superior wear/extrusion resistance, lower fill percentage needed, non-abrasive to soft metals | Dynamic seals, dry-running systems, components against soft metal surfaces |

| Particulate Fillers | High compressive strength, general durability, cost-effective | Static seals, hydraulic piston rings, components under high load |

Still Unsure Which PTFE Filler is Right for Your Project?

Choosing the optimal filler is critical for the performance and longevity of your components. KINTEK specializes in manufacturing precision PTFE components with both fibrous and particulate fillers for the semiconductor, medical, laboratory, and industrial sectors.

We provide expert guidance to help you select the perfect material based on your specific requirements for wear resistance, compressive strength, chemical compatibility, and cost. From custom prototypes to high-volume production, we ensure your parts meet the highest standards.

Contact our material experts today to discuss your application and receive a tailored solution.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Square Trays for Industrial and Laboratory Use

People Also Ask

- How is PTFE used in industrial processes? Maximize Safety and Efficiency

- How does PTFE compare to other low-friction plastics like UHMW-PE and Nylon? A Guide to Material Selection

- What is the working temperature range of PTFE? Master Extreme Heat and Cryogenic Applications

- What are some important physical property values for PTFE? Master Its Extreme Performance for Demanding Applications

- When and by whom was PTFE discovered? A Tale of Accidental Innovation