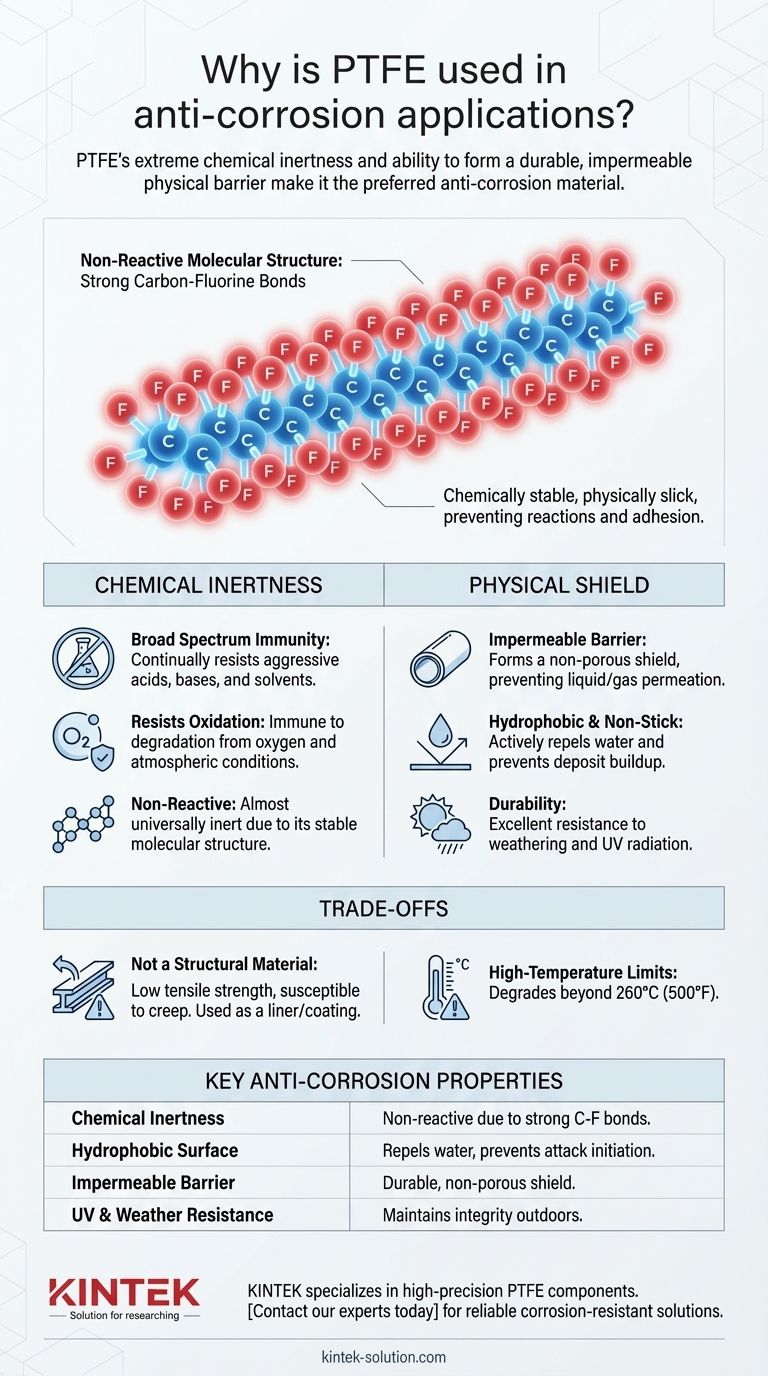

The fundamental reason PTFE is used in anti-corrosion applications is its extreme chemical inertness and its ability to form a durable, impermeable physical barrier. Its unique molecular structure makes it non-reactive to nearly all industrial chemicals, acids, and solvents, while its hydrophobic nature repels water and other corrosive liquids, effectively shielding the underlying material from attack.

The core of PTFE's protective power lies in its chemistry. The incredibly strong carbon-fluorine bonds create a molecule that is both chemically stable and physically slick, preventing corrosive substances from reacting with it or even adhering to its surface.

The Foundation of PTFE's Resistance: Chemical Inertness

Polytetrafluoroethylene (PTFE) is not just resistant to corrosion; for most practical purposes, it is immune to chemical attack. This exceptional property is the primary reason it is specified for the most demanding environments.

A Non-Reactive Molecular Structure

At a molecular level, PTFE consists of a long chain of carbon atoms completely shielded by a sheath of fluorine atoms. The carbon-fluorine bond is one of the strongest in organic chemistry.

This stable, tightly-bonded structure leaves no easy way for other chemicals to attack or react with the polymer chain, rendering the material almost universally inert.

Broad Spectrum Chemical Immunity

Because of its molecular stability, PTFE can be continuously exposed to a vast range of aggressive substances without degrading.

This includes highly corrosive acids, bases, solvents, and other caustic chemicals that would quickly destroy metals, alloys, and other polymers.

Resisting Oxidation

PTFE does not react with oxygen, meaning it is immune to oxidation, a very common form of chemical degradation and corrosion that affects metals and many plastics.

This property ensures it maintains its integrity and plasticity over long periods, even with constant exposure to fluids and atmospheric conditions.

How PTFE Acts as a Physical Shield

Beyond its chemical inertness, PTFE's physical properties create a robust barrier that prevents corrosive agents from ever reaching the substrate it protects.

Creating an Impermeable Barrier

PTFE is used extensively as a coating or a liner for pipes, tanks, valves, and chemical equipment.

In this role, it functions as a complete physical shield. Its low porosity prevents corrosive liquids and gases from permeating through to the structural material beneath.

A Hydrophobic and Non-Stick Surface

PTFE is profoundly hydrophobic, meaning it actively repels water. This prevents moisture from adhering to the surface, which is a critical first step in many corrosion processes.

This same property makes it non-stick, which prevents the buildup of deposits that could trap corrosive agents against the surface. This is particularly valuable in pipes and vessels.

Durability Against Environmental Factors

For outdoor or exposed equipment, PTFE provides excellent resistance to weathering and UV radiation.

Unlike many other plastics that become brittle and crack with sun exposure, PTFE remains stable, ensuring the protective barrier does not degrade over time.

Understanding the Trade-offs

While its anti-corrosion properties are exceptional, PTFE is not a universal solution. Understanding its limitations is key to using it effectively.

Not a Structural Material

PTFE has relatively low tensile strength and can be susceptible to creep under load. It is rarely used for primary structural components.

Its value is most often realized as a liner, coating, or component (like a gasket or seal) that is supported by a structural metal or composite.

High-Temperature Limits

PTFE has a high continuous service temperature for a polymer, typically up to 260°C (500°F).

However, beyond this temperature, it will begin to degrade. This makes it unsuitable for applications that exceed this thermal limit, where exotic metal alloys might be required.

Making the Right Choice for Your Application

Selecting PTFE is about matching its unique strengths to a specific environmental challenge.

- If your primary focus is handling aggressive chemicals: PTFE's near-total chemical inertness makes it the definitive choice for linings and components in direct, continuous contact with corrosives.

- If your primary focus is protecting equipment from environmental factors: PTFE's hydrophobic and UV-resistant properties create a durable shield against moisture, road salt, and weathering.

- If your primary focus is on process purity: PTFE's non-reactive nature ensures it will not leach or contaminate sensitive materials, making it essential in biotech, pharmaceutical, and semiconductor manufacturing.

Ultimately, selecting PTFE is a strategic decision for achieving unparalleled material longevity and reliability in the most demanding corrosive conditions.

Summary Table:

| Key Property | Why It Fights Corrosion |

|---|---|

| Chemical Inertness | Non-reactive to nearly all acids, bases, and solvents due to strong carbon-fluorine bonds. |

| Hydrophobic Surface | Repels water and prevents corrosive liquids from adhering or initiating attack. |

| Impermeable Barrier | Forms a durable, non-porous shield as a liner or coating to protect underlying materials. |

| UV & Weather Resistance | Maintains integrity and plasticity outdoors, unlike many other plastics that degrade. |

Need a reliable corrosion-resistant solution for your equipment?

KINTEK specializes in manufacturing high-precision PTFE components—including custom seals, liners, and labware—specifically for industries like semiconductor, medical, and industrial processing where chemical resistance is critical. We combine precision production with custom fabrication, from prototypes to high-volume orders, to deliver the durability and purity your application demands.

Contact our experts today to discuss how our PTFE solutions can protect your assets and extend their service life.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Square Trays for Industrial and Laboratory Use

- Custom PTFE Volumetric Flasks for Advanced Scientific and Industrial Use

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

People Also Ask

- Why is PTFE rod suitable for automotive applications? Boost Vehicle Performance & Durability

- Why is CNC machining preferred for Teflon parts over other methods? Unlock Precision & Complex Designs

- What are the main advantages of using PTFE parts in industrial applications? Unlock Unmatched Chemical Resistance and Reliability

- What industries use PTFE machined parts and for what applications? Critical Components for Demanding Environments

- What are the key considerations when machining Teflon? Master Precision Machining for Soft Polymers