In short, O-ring materials are defined by their resilience in extreme environments. They typically offer a wide operational temperature range, from -60°C to 250°C, and excellent resistance to weathering, high-pressure steam, and specific chemicals like phosphate ester-based hydraulic oils. However, their notable weakness is a poor resistance to general mineral oils and lubricants.

The core challenge in selecting an O-ring is not finding a "good" material, but finding the correct material. A material's strength in one application, like sealing against steam, can be a critical failure point in another, such as contact with mineral oil.

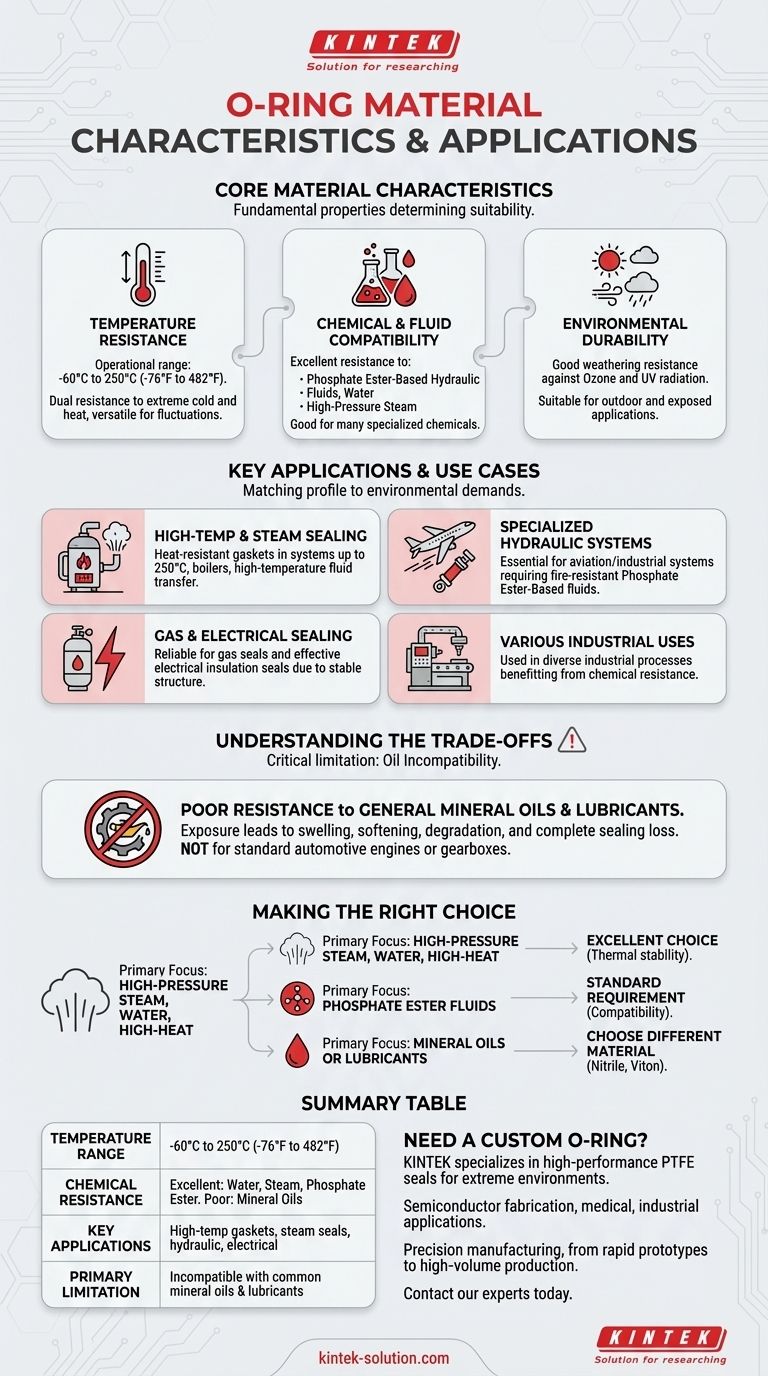

Core Material Characteristics

To understand where an O-ring excels, we must first break down its fundamental properties. These characteristics determine its suitability for a given sealing application.

Temperature Resistance

The operational temperature range is a primary feature, typically spanning from -60°C (-76°F) to 250°C (482°F).

This dual resistance to both cold and heat makes the material exceptionally versatile for environments with significant temperature fluctuations or those operating at consistent extremes.

Chemical and Fluid Compatibility

This is the most critical factor for ensuring seal longevity. These materials show strong resistance to phosphate ester-based hydraulic fluids, water, and high-pressure steam.

They also have good resistance to many other chemicals, which contributes to their wide range of uses in specialized industrial processes.

Environmental Durability

The materials possess good weathering resistance. This means they hold up well against environmental factors like ozone and UV radiation, making them suitable for outdoor applications or where exposure to air is a concern.

Key Applications and Use Cases

The specific properties of these O-rings directly translate to their most common and effective applications. The material is chosen because its profile precisely matches the demands of the environment.

High-Temperature and Steam Sealing

Due to their high heat tolerance up to 250°C, these O-rings are a primary choice for heat-resistant gaskets in systems involving high-pressure steam, boilers, and other high-temperature fluid or gas transfer.

Specialized Hydraulic Systems

The specific resistance to phosphate ester-based hydraulic oils makes them essential components in certain aviation and industrial hydraulic systems where these types of fluids are required for fire resistance.

Gas and Electrical Sealing

Their durability and stable structure make them reliable for gas seals in various industrial applications. Furthermore, their inherent material properties allow them to serve as effective electrical insulation seals, preventing the flow of current.

Understanding the Trade-offs

No material is a universal solution. Understanding a material's limitations is just as important as knowing its strengths to prevent costly system failures.

The Critical Limitation: Oil Incompatibility

The most significant drawback is a poor resistance to general mineral oils and lubricants.

When exposed to these common substances, the O-ring material can swell, soften, and degrade rapidly, leading to a complete loss of sealing integrity.

Mismatching Leads to Failure

The most common cause of failure is not a defect in the material itself, but an incorrect application. Using this type of O-ring in a standard automotive engine or gearbox, which relies on mineral-based lubricants, would guarantee a fast and predictable failure.

Making the Right Choice for Your Application

Your final decision must be based on the specific operating environment of your system.

- If your primary focus is sealing against high-pressure steam, water, or in high-heat conditions: This material's thermal stability makes it an excellent and reliable choice.

- If your primary focus is a hydraulic system using phosphate ester fluids: This material is specifically designed for compatibility and is often the standard requirement.

- If your primary focus is sealing any system that uses common mineral oils or lubricants: You must choose a different material, such as Nitrile (Buna-N) or Viton, to avoid rapid degradation and seal failure.

Ultimately, matching the material's chemical and thermal profile to your application's demands is the key to creating a reliable, long-lasting seal.

Summary Table:

| Characteristic | Key Details |

|---|---|

| Temperature Range | -60°C to 250°C (-76°F to 482°F) |

| Chemical Resistance | Excellent for water, steam, phosphate ester fluids; Poor for mineral oils |

| Key Applications | High-temperature gaskets, steam seals, specialized hydraulic systems, electrical insulation |

| Primary Limitation | Incompatible with common mineral oils and lubricants |

Need a Custom O-Ring for a Demanding Application?

Your sealing challenges are unique. KINTEK specializes in manufacturing high-performance PTFE seals and components that excel in extreme temperatures and harsh chemical environments, from semiconductor fabrication to medical and industrial applications.

We prioritize precision and offer custom fabrication—from rapid prototypes to high-volume production—ensuring you get the exact seal you need for reliability and longevity.

Contact our experts today to discuss your specific requirements and get a solution tailored to your operational demands.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Teflon Balls for Advanced Industrial Applications

People Also Ask

- What are the main advantages of using PTFE parts in industrial applications? Unlock Unmatched Chemical Resistance and Reliability

- What industries use PTFE machined parts and for what applications? Critical Components for Demanding Environments

- What are the key considerations when machining Teflon? Master Precision Machining for Soft Polymers

- Why is CNC machining preferred for Teflon parts over other methods? Unlock Precision & Complex Designs

- What are the future considerations for machining Teflon? Mastering Material Challenges with Smart Tech