In short, Teflon bushes offer exceptional performance in chemically harsh environments. Their unique molecular structure makes them one of the most chemically inert materials available for engineering applications. This means they remain stable and functional when exposed to a wide range of corrosive substances that would degrade most other materials.

The outstanding performance of Teflon (PTFE) bushes in harsh environments stems from their inherent chemical inertness. This stability makes them virtually impervious to most acids, solvents, and corrosive agents, ensuring reliability and longevity where other materials would quickly fail.

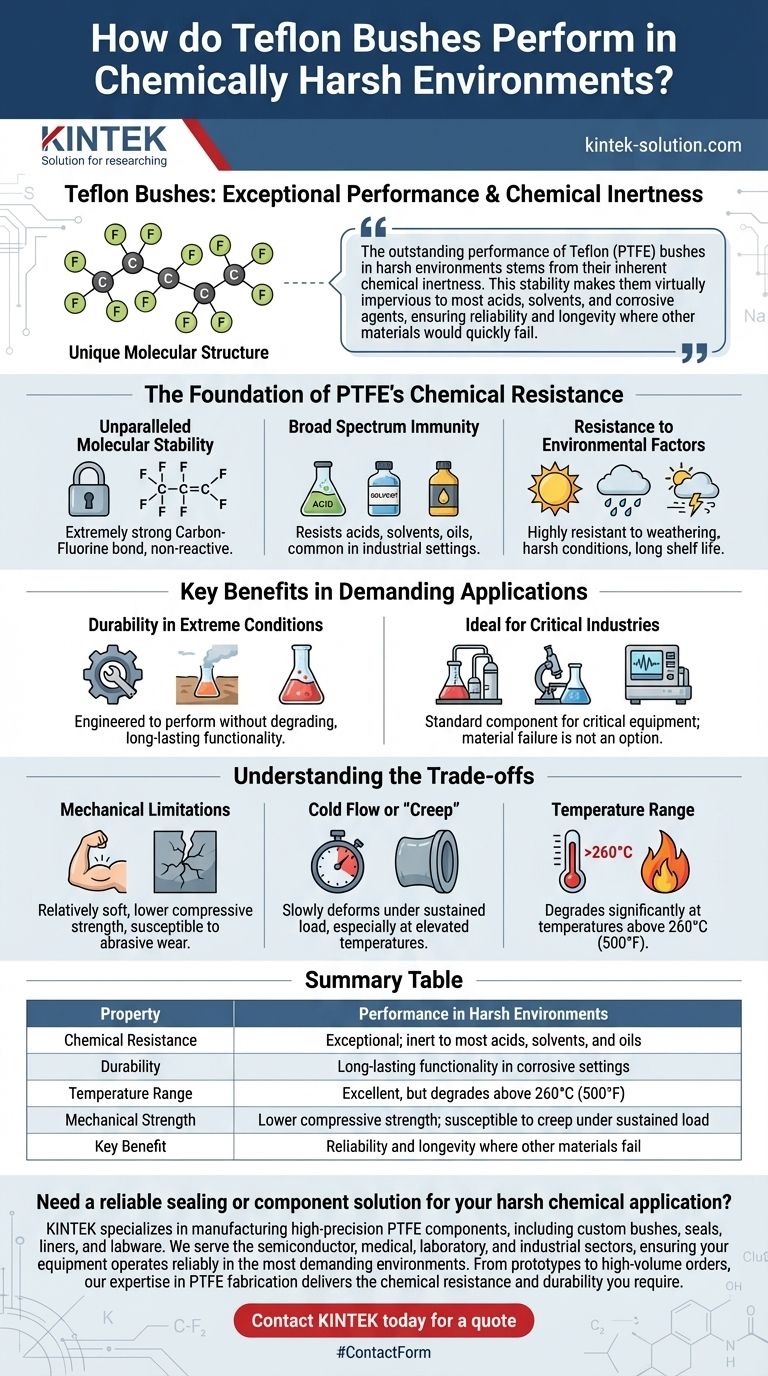

The Foundation of PTFE's Chemical Resistance

To understand why Teflon (a brand name for PTFE) excels, we need to look at its core properties. Its resilience isn't an added feature; it's fundamental to the material itself.

Unparalleled Molecular Stability

At a molecular level, PTFE is built on an extremely strong carbon-fluorine bond. This bond is so stable that very few chemicals have the energy to break it apart, rendering the material non-reactive.

Broad Spectrum Immunity

This chemical stability translates to a remarkable resistance against a vast array of corrosive substances. This includes aggressive agents such as acids, solvents, and oils that are common in industrial settings.

Resistance to Environmental Factors

Teflon's durability isn't limited to direct chemical contact. The material is highly resistant to weathering and is not affected by harsh environmental conditions or contaminants, ensuring it maintains its properties over a long shelf life.

Key Benefits in Demanding Applications

This inherent resistance provides tangible benefits in the field, making PTFE a go-to solution for engineers facing challenging operational conditions.

Durability in Extreme Conditions

PTFE bushes are engineered to perform without degrading. This ensures long-lasting functionality and reliability, even when operating continuously within harsh chemical or environmental settings.

Ideal for Critical Industries

Because of this reliability, Teflon bushes are frequently specified for critical equipment. They are a standard component in chemical plants, laboratories, and pharmaceutical machinery where material failure is not an option.

Understanding the Trade-offs

While its chemical resistance is nearly unmatched, Teflon's suitability depends on the full range of operational demands. As with any engineering material, there are important trade-offs to consider.

Mechanical Limitations

PTFE is a relatively soft material. Compared to metals or other engineering plastics, it has lower compressive strength and can be susceptible to abrasive wear if not properly applied.

Cold Flow or "Creep"

Under a sustained load, especially at elevated temperatures, PTFE can slowly deform over time. This phenomenon, known as creep or cold flow, must be accounted for in high-load bearing applications.

Temperature Range

While PTFE has an excellent operating temperature range, it is not infinite. Its mechanical properties begin to degrade significantly at temperatures above 260°C (500°F), which may be a limitation in some extreme-heat processes.

Making the Right Choice for Your Application

Selecting the correct bushing material requires balancing chemical needs with mechanical and thermal demands.

- If your primary focus is maximum chemical inertness: Teflon (PTFE) is almost certainly the superior choice, offering peace of mind against nearly all corrosive agents.

- If your primary focus is high mechanical loads or abrasion resistance: You may need to consider a filled or blended grade of PTFE, or an alternative high-performance polymer designed for structural strength.

- If your primary focus is long-term stability and reliability: PTFE's resistance to both chemicals and general weathering makes it an excellent candidate for components that require a long and predictable service life.

Ultimately, understanding both the strengths and limitations of Teflon ensures you can leverage its unparalleled chemical resistance to build more robust and reliable systems.

Summary Table:

| Property | Performance in Harsh Environments |

|---|---|

| Chemical Resistance | Exceptional; inert to most acids, solvents, and oils |

| Durability | Long-lasting functionality in corrosive settings |

| Temperature Range | Excellent, but degrades above 260°C (500°F) |

| Mechanical Strength | Lower compressive strength; susceptible to creep under sustained load |

| Key Benefit | Reliability and longevity where other materials fail |

Need a reliable sealing or component solution for your harsh chemical application?

KINTEK specializes in manufacturing high-precision PTFE components, including custom bushes, seals, liners, and labware. We serve the semiconductor, medical, laboratory, and industrial sectors, ensuring your equipment operates reliably in the most demanding environments. From prototypes to high-volume orders, our expertise in PTFE fabrication delivers the chemical resistance and durability you require.

Contact KINTEK today to discuss your specific needs and get a quote for your project.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Custom PTFE Square Trays for Industrial and Laboratory Use

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

People Also Ask

- What industries use PTFE machined parts and for what applications? Critical Components for Demanding Environments

- What are the best practices for achieving tight tolerances in Teflon (PTFE) machining? Master Precision for Demanding Applications

- What are the main advantages of using PTFE parts in industrial applications? Unlock Unmatched Chemical Resistance and Reliability

- How does PTFE contribute to low friction and wear resistance? Achieve Superior Performance with Advanced Materials

- What are the key considerations when machining Teflon? Master Precision Machining for Soft Polymers