The suitability of Teflon (PTFE) for machining stems from a unique combination of beneficial properties for the final component, including a very low friction coefficient, exceptional chemical resistance, and high-temperature stability. These characteristics make it a valuable material for parts used in demanding aerospace, automotive, and chemical processing environments.

The core challenge of machining PTFE is not leveraging its strengths but rather mitigating its weaknesses. Its inherent softness, poor heat dissipation, and high rate of thermal expansion require a specific approach that is fundamentally different from machining metals or even other plastics.

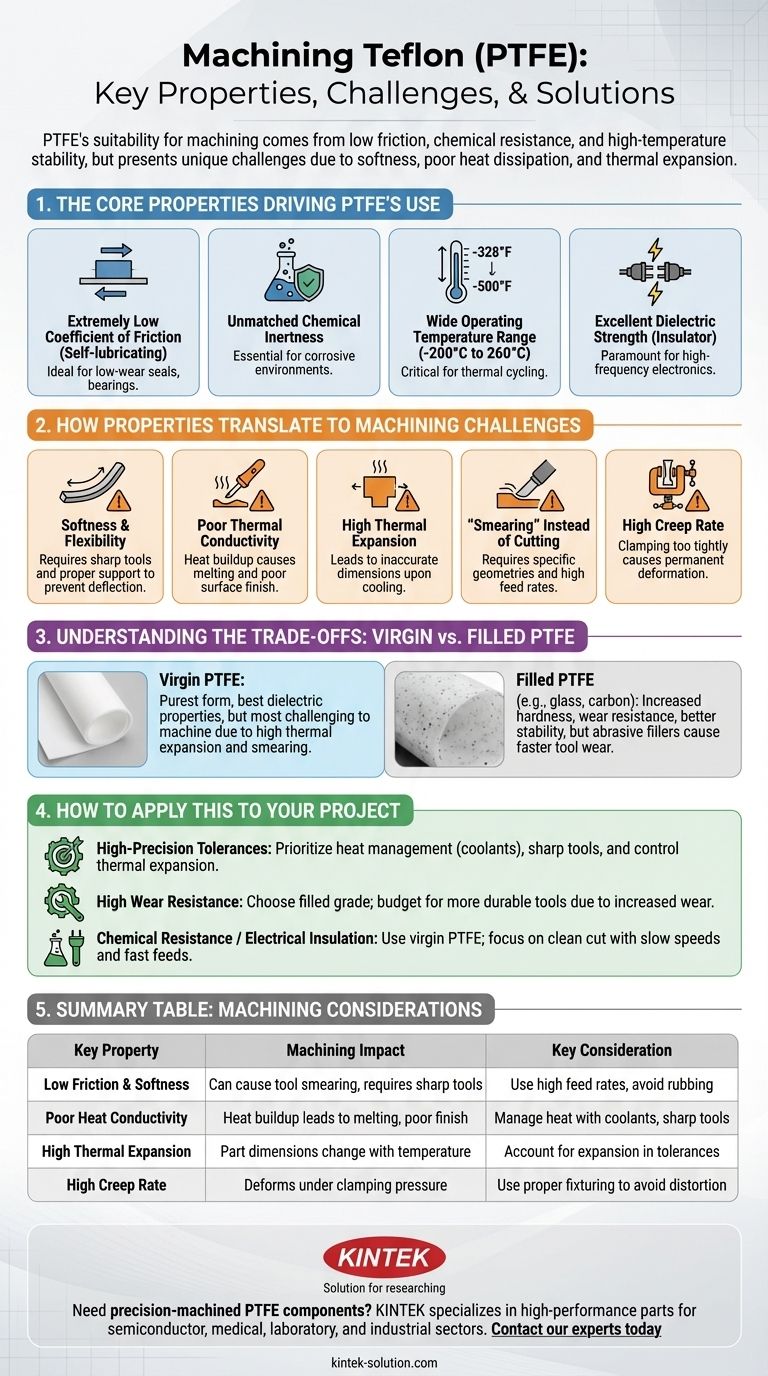

The Core Properties Driving PTFE's Use

While PTFE is valued for its performance in finished parts, these same properties create the context for its machining behavior.

Extremely Low Coefficient of Friction

PTFE has one of the lowest friction coefficients of any solid material, often compared to wet ice on wet ice. This makes it self-lubricating and ideal for creating low-wear seals, bearings, and bushings.

Unmatched Chemical Inertness

The material is almost completely inert, meaning it does not react with the vast majority of industrial chemicals. This makes it essential for components used in corrosive environments.

Wide Operating Temperature Range

PTFE maintains its properties across an exceptionally broad temperature spectrum, from cryogenic levels (-328°F / -200°C) up to 500°F (260°C). This stability is critical for components that experience extreme thermal cycling.

Excellent Dielectric Strength

As a superior electrical insulator, PTFE is frequently machined into components for high-frequency electronics and connectors where signal integrity is paramount.

How These Properties Translate to Machining Challenges

The very properties that make PTFE a high-performance material also introduce distinct challenges that must be managed during the machining process.

Softness and Flexibility

PTFE is a soft material that can easily deform or compress under pressure. This requires extremely sharp cutting tools and proper workpiece support to prevent deflection and ensure dimensional accuracy.

Poor Thermal Conductivity

Unlike metals, PTFE does not conduct heat away from the cutting tool effectively. Heat builds up at the cutting edge, which can cause the material to melt, gum up, and stick to the tool, resulting in a poor surface finish.

High Thermal Expansion

The material expands and contracts significantly with temperature changes. Heat generated during machining can cause the part to grow, leading to inaccurate dimensions once it cools down.

"Smearing" Instead of Cutting

PTFE's non-stick, low-friction surface can cause tools to rub or "smear" the material instead of shearing it cleanly. This requires specific tool geometries and high feed rates to ensure a chip is properly formed and evacuated.

High Creep Rate

PTFE has a tendency to deform slowly over time when subjected to constant pressure. This means that clamping a workpiece too tightly in a vise can cause it to permanently deform, compromising the final part's geometry.

Understanding the Trade-offs: Virgin vs. Filled PTFE

Not all PTFE is the same. The addition of fillers like glass or carbon fundamentally changes its machining characteristics.

Machining Virgin PTFE

Virgin PTFE is the purest form and is extremely soft, chemically resistant, and has the best dielectric properties. It is also the most challenging to machine precisely due to its high thermal expansion and tendency to smear.

Machining Filled Grades

Filled PTFE (e.g., glass-filled, carbon-filled) incorporates additives that increase hardness, wear resistance, and dimensional stability. While these grades are easier to machine to tight tolerances, the abrasive fillers cause significantly faster tool wear.

How to Apply This to Your Project

Your machining strategy must be dictated by the material's properties and your desired outcome.

- If your primary focus is high-precision tolerances: You must prioritize heat management through coolants, sharp tools, and controlling the material's high thermal expansion.

- If your primary focus is high wear resistance: Choose a filled grade of PTFE but be prepared for increased tool wear and budget for more durable or specialized cutting tools.

- If your primary focus is chemical resistance or electrical insulation: Use virgin PTFE and focus your technique on achieving a clean cut by using slow speeds and fast feeds to prevent melting and smearing.

Ultimately, mastering PTFE machining is less about the material's strengths and more about respecting its unique physical challenges.

Summary Table:

| Key Property | Machining Impact | Key Consideration |

|---|---|---|

| Low Friction & Softness | Can cause tool smearing, requires sharp tools | Use high feed rates, avoid rubbing |

| Poor Heat Conductivity | Heat buildup leads to melting, poor finish | Manage heat with coolants, sharp tools |

| High Thermal Expansion | Part dimensions change with temperature | Account for expansion in tolerances |

| High Creep Rate | Deforms under clamping pressure | Use proper fixturing to avoid distortion |

Need precision-machined PTFE components that leverage its strengths while overcoming its challenges? KINTEK specializes in machining high-performance PTFE parts for the semiconductor, medical, laboratory, and industrial sectors. We combine expertise in material science with advanced machining techniques to deliver custom seals, liners, and labware—from prototypes to high-volume orders—that meet your exact specifications. Contact our experts today to discuss your project and get a quote!

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Customizable PTFE Rods for Advanced Industrial Applications

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

People Also Ask

- What operational advantages do PTFE slide bearings offer in construction projects? Achieve Maintenance-Free Structural Movement

- What are the key differences between machining filled and unfilled PTFE? Optimize Your Process for Performance

- What are the main industrial applications of PTFE impellers? Handling Corrosive & High-Purity Processes

- What types of parts can be fabricated using PTFE machining? Seals, Bushings, Insulators & More

- What is RPTFE and why is it commonly used for valve seats? Enhance Durability in Demanding Applications

- What is PTFE and why is it used in lined valves? Achieve Superior Corrosion Resistance and Purity

- What are the different types of PTFE seals available? Find the Right Seal for Static or Dynamic Applications

- What nominal sizes are available for PTFE gaskets? From DN15 to DN2000 and Beyond