PTFE-lined diaphragm valves are exceptionally suited for wastewater treatment because their core design combines near-universal chemical inertness with a mechanically simple, leak-proof sealing mechanism. This enables them to reliably handle the highly acidic, abrasive, and corrosive fluids common in purification and disposal processes while minimizing maintenance and preventing environmental contamination.

The true value of a PTFE-lined diaphragm valve in wastewater isn't just its material resilience, but how that resilience translates directly into lower operational costs, enhanced safety, and long-term system integrity in a highly corrosive environment.

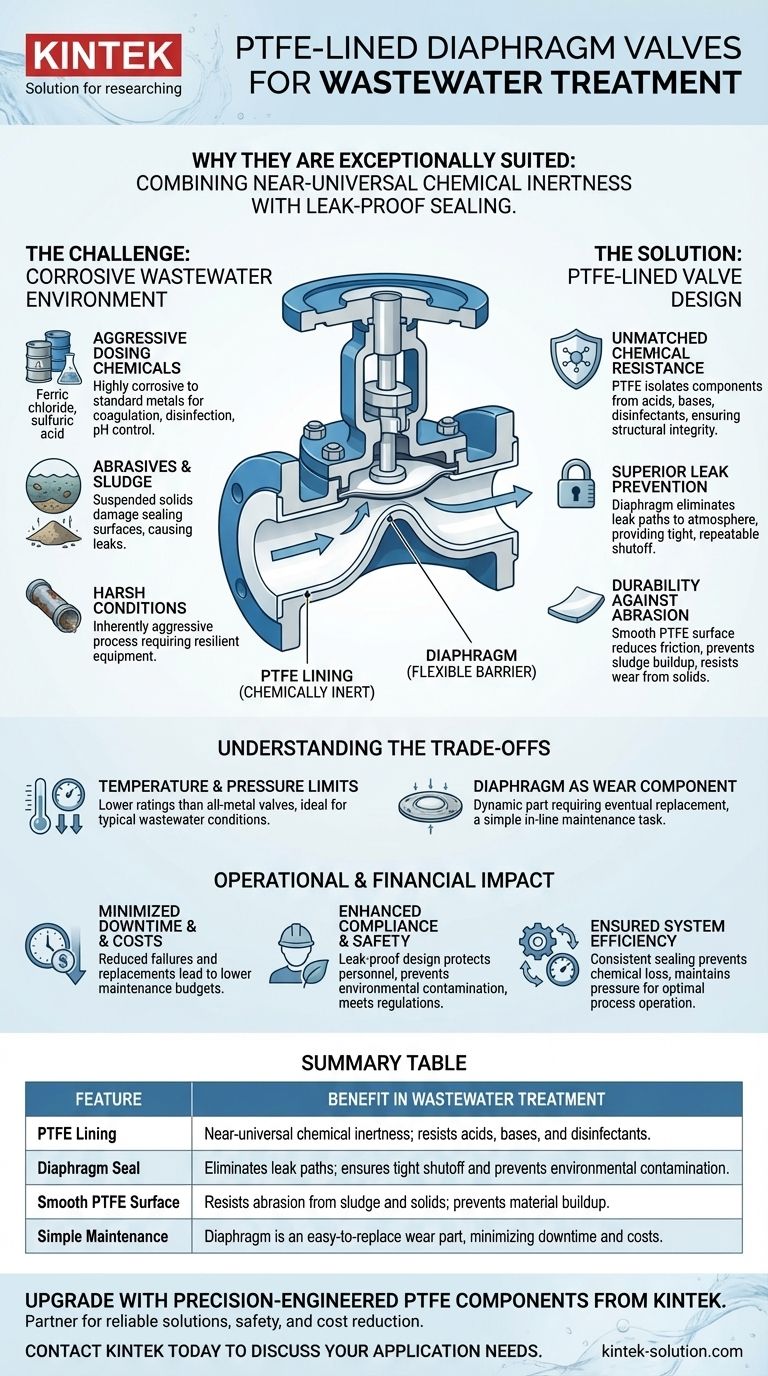

The Core Challenge: The Corrosive Nature of Wastewater

Wastewater treatment is an inherently aggressive process. The chemicals used and the byproducts created pose a significant challenge to any mechanical equipment, especially valves.

Handling Aggressive Dosing Chemicals

Treatment processes rely on a host of chemicals like ferric chloride, sodium hypochlorite, and sulfuric acid for coagulation, disinfection, and pH control. These substances are highly corrosive to standard metals.

The Problem of Abrasives and Sludge

Beyond chemicals, the media itself often contains suspended solids, grit, and sludge. These abrasive particles can easily damage the sealing surfaces of traditional valves, leading to leaks and failures.

How PTFE-Lined Diaphragm Valves Meet the Challenge

The specific design of these valves directly counters the harsh conditions of wastewater applications, making them a preferred engineering choice.

Unmatched Chemical Resistance

Polytetrafluoroethylene (PTFE) is one of the most chemically inert polymers available. A PTFE lining isolates all valve components from the process media, preventing corrosion from acids, bases, and disinfectants.

This universal resistance ensures the valve maintains its structural integrity and performance over a long service life, regardless of variations in chemical dosing.

Superior Leak Prevention and Sealing

The diaphragm acts as a flexible, pressure-responsive barrier. It separates the fluid path from the valve's operating mechanism (the bonnet), completely eliminating a potential leak path to the atmosphere.

This design provides a tight, repeatable shutoff, which is critical for preventing the escape of hazardous chemicals and ensuring accurate flow control within the system.

Durability Against Wear and Abrasion

The smooth, non-stick surface of the PTFE lining reduces friction and prevents sludge or other solids from adhering to the valve's interior.

Furthermore, the diaphragm's gentle closing action—pressing down onto a weir—is far less susceptible to wear from abrasive particles than the sliding or rotating seals found in gate or ball valves.

Understanding the Trade-offs

While highly effective, it's important to understand the operational limits of PTFE-lined diaphragm valves to ensure proper application.

Temperature and Pressure Limitations

PTFE and the elastomeric materials that support the diaphragm have lower temperature and pressure ratings than all-metal valves. They are ideal for the typical conditions of wastewater treatment but may not be suitable for high-pressure or high-temperature specialty applications.

Diaphragm as a Wear Component

The diaphragm is a dynamic component that flexes with each cycle. While designed for millions of cycles, it is a wear part that will eventually require replacement. However, this is typically a simple, in-line maintenance task that does not require removing the entire valve body.

The Operational and Financial Impact

The technical advantages of these valves deliver tangible benefits in terms of cost, safety, and efficiency.

Minimizing Downtime and Maintenance Costs

Their durability and resistance to both chemical and abrasive wear dramatically reduce the frequency of failures and required replacements. This leads to less process downtime and lower long-term maintenance budgets.

Enhancing Environmental Compliance and Safety

The leak-proof design is a critical safety feature. It protects plant personnel from exposure to hazardous chemicals and prevents environmental contamination from spills, helping facilities meet strict regulatory requirements.

Ensuring System Efficiency

Consistent, tight sealing prevents the loss of expensive treatment chemicals and maintains system pressure. This ensures the entire treatment process operates as designed, without the inefficiencies caused by leaking or failing components.

Making the Right Choice for Your System

Selecting the right valve is a strategic decision based on your primary operational goals.

- If your primary focus is reliability in highly corrosive service: The robust chemical resistance and leak-proof design of a PTFE-lined diaphragm valve make it a superior choice for handling treatment chemicals.

- If your primary focus is lowering operational costs: Their durability and minimal maintenance requirements directly translate into reduced downtime and lower long-term expenditures.

- If your primary focus is environmental compliance and safety: The valve's tight seal and non-reactive materials prevent hazardous leaks, protecting both personnel and the environment.

Ultimately, selecting a PTFE-lined diaphragm valve is a strategic decision for ensuring the long-term integrity and efficiency of your wastewater treatment process.

Summary Table:

| Feature | Benefit in Wastewater Treatment |

|---|---|

| PTFE Lining | Near-universal chemical inertness; resists acids, bases, and disinfectants. |

| Diaphragm Seal | Eliminates leak paths; ensures tight shutoff and prevents environmental contamination. |

| Smooth PTFE Surface | Resists abrasion from sludge and solids; prevents material buildup. |

| Simple Maintenance | Diaphragm is an easy-to-replace wear part, minimizing downtime and costs. |

Upgrade your wastewater treatment system with precision-engineered PTFE components from KINTEK.

Our expertise in custom fabricating high-performance PTFE seals, liners, and labware ensures your valves and equipment can withstand the harshest corrosive and abrasive environments. We partner with semiconductor, medical, laboratory, and industrial clients to deliver reliable solutions—from prototypes to high-volume orders—that enhance safety, reduce operational costs, and ensure compliance.

Contact KINTEK today to discuss your specific application needs and receive a custom solution quote.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

- Custom PTFE and Nitrile Diaphragm Pump Components for Demanding Applications

- Customizable PTFE Seals Filter Holders for Versatile Applications

People Also Ask

- What factors should be considered when choosing between Nylon and PTFE? Select the Right Material for Your Application

- What chemical processing applications involve PTFE-machined parts? Essential Components for Corrosive & High-Purity Systems

- What are the main applications of PTFE type Teflon? Unlock Its Versatility for Your Industry

- What are the unique properties of PTFE? The 3 Pillars Driving Demand for High-Performance Parts

- What industrial benefits do PTFE-machined parts offer? Achieve Peak Performance in Demanding Applications