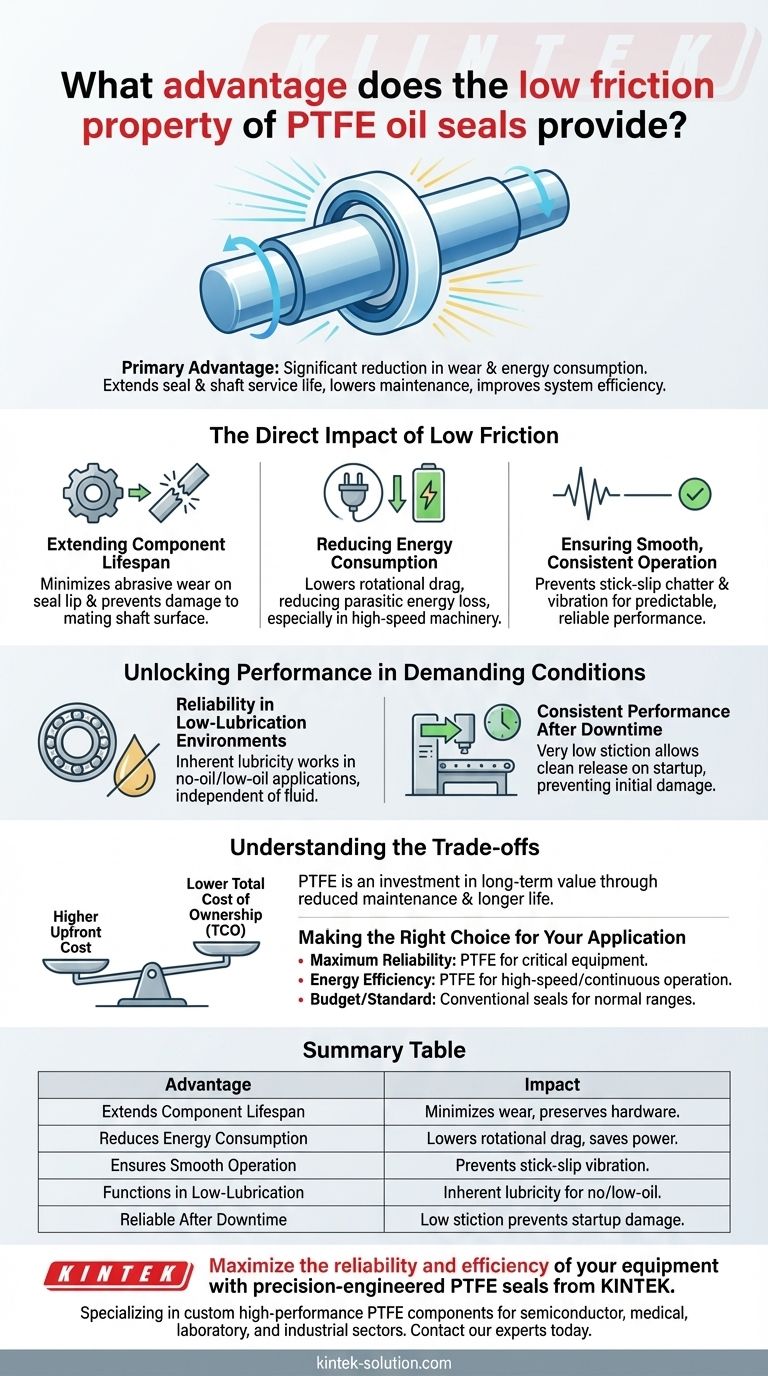

The primary advantage of the low friction property of PTFE oil seals is a significant reduction in both operational wear and energy consumption. This unique characteristic allows the seal to operate smoothly against a rotating shaft, which directly extends the service life of both the seal and the shaft itself, leading to lower maintenance costs and improved system efficiency.

While often seen as a simple durability feature, the low friction of PTFE fundamentally redefines a seal's role. It enables reliable performance in demanding conditions where traditional seals would quickly fail, such as high-speed rotation or poor lubrication, ultimately lowering the total cost of ownership.

The Direct Impact of Low Friction

The coefficient of friction is a measure of the resistance to motion between two surfaces in contact. For a rotating shaft seal, this value has direct and immediate consequences for the entire system.

Extending Component Lifespan

Friction generates heat and causes abrasive wear. In a traditional rubber seal, this constant rubbing can wear down the seal lip and, more critically, score a groove into the steel shaft over time.

PTFE's extremely low coefficient of friction minimizes this abrasive action. This dramatically reduces wear on the seal lip and, just as importantly, prevents damage to the mating shaft surface, preserving the integrity of expensive hardware.

Reducing Energy Consumption

Every bit of friction in a dynamic system is a force that the motor must overcome, consuming energy. While this may seem minor for a single seal, the effect is compounded in high-speed machinery or systems running continuously.

By minimizing rotational drag, PTFE seals reduce the parasitic energy loss caused by friction. In applications like high-speed impellers or automotive powertrains, this can result in measurable power savings and improved overall efficiency.

Ensuring Smooth, Consistent Operation

High friction can lead to a phenomenon known as "stick-slip," where the seal alternately sticks to and slips from the shaft surface. This causes chatter, vibration, and uneven wear.

PTFE's inherent lubricity ensures a smooth, continuous contact with the shaft. This stable operation prevents damaging vibrations and contributes to a more predictable and reliable sealing performance over the long term.

Unlocking Performance in Demanding Conditions

The benefits of low friction extend beyond simple wear and efficiency. This property allows PTFE seals to perform reliably in environments where conventional elastomeric seals would not be suitable.

Reliability in Low-Lubrication Environments

Many seals rely on the system's fluid (e.g., oil) to create a hydrodynamic film that reduces friction. If this lubrication is minimal or absent, a conventional seal will generate high friction and heat, leading to rapid failure.

PTFE seals are excellent for no-oil or low-oil applications because their low-friction nature is an inherent material property, not dependent on external lubrication.

Consistent Performance After Downtime

After a machine has been shut down, a traditional rubber seal can "stick" to the shaft surface. When the machine restarts, it requires a high initial torque to break this adhesion, which can damage the seal lip.

PTFE seals exhibit very low "stiction" or static friction. This means they release cleanly from the shaft on startup, even after prolonged periods of inactivity, ensuring a smooth start with no risk of initial damage.

Understanding the Trade-offs

While PTFE offers superior friction characteristics, it is not the universal solution for every sealing application. Understanding its context against conventional seals is key to making a sound engineering decision.

The Cost vs. Performance Equation

PTFE seals are typically associated with a higher upfront cost compared to standard nitrile or FKM (Viton) rubber seals. Their benefits are realized in reduced maintenance, less downtime, and longer equipment life.

The decision to use PTFE is an investment in lowering the total cost of ownership for the equipment, rather than minimizing the initial component price.

When a Conventional Seal Is Sufficient

For many common applications with moderate speeds, stable temperatures, and adequate lubrication, a conventional elastomeric oil seal performs reliably and is a highly cost-effective choice.

PTFE becomes the necessary choice when the operational demands—such as high shaft speeds, extreme temperatures, aggressive chemicals, or poor lubrication—exceed the capabilities of traditional materials.

Making the Right Choice for Your Application

Selecting the correct seal material requires you to balance performance requirements with budget constraints. Your primary operational goal should guide your decision.

- If your primary focus is maximum reliability and long service life: PTFE is the superior choice for reducing wear on both the seal and the shaft, especially in critical or hard-to-service equipment.

- If your primary focus is energy efficiency: For high-speed or continuously operating machinery, the lower rotational drag of a PTFE seal translates directly into tangible power savings.

- If your primary focus is budget for standard applications: A conventional elastomeric seal often provides the most cost-effective solution for systems operating within normal temperature and speed ranges.

Ultimately, choosing a seal based on its performance under your specific operational demands ensures the best possible outcome for both reliability and cost.

Summary Table:

| Advantage | Impact |

|---|---|

| Extends Component Lifespan | Minimizes wear on seal and shaft, preserving expensive hardware. |

| Reduces Energy Consumption | Lowers rotational drag, saving power in high-speed/continuous machinery. |

| Ensures Smooth Operation | Prevents stick-slip vibration for consistent, reliable performance. |

| Functions in Low-Lubrication | Inherent lubricity allows use in no-oil or low-oil environments. |

| Reliable After Downtime | Low stiction prevents damage on startup after periods of inactivity. |

Maximize the reliability and efficiency of your equipment with precision-engineered PTFE seals from KINTEK.

For engineers and procurement specialists in the semiconductor, medical, laboratory, and industrial sectors, the right seal is critical to minimizing downtime and total cost of ownership. KINTEK specializes in the custom fabrication of high-performance PTFE components—including seals, liners, and labware—designed to meet the exact demands of your application, from prototypes to high-volume production.

Let us help you select or design the perfect sealing solution to extend component life, reduce energy costs, and ensure unwavering performance. Contact our experts today to discuss your requirements.

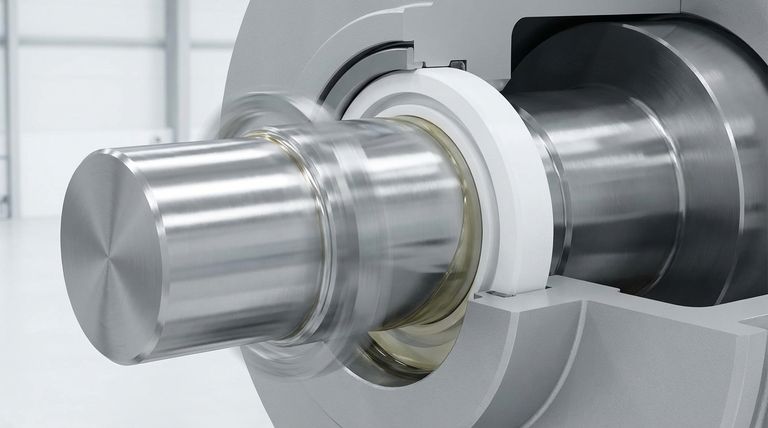

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Customizable PTFE Seals Filter Holders for Versatile Applications

People Also Ask

- What are the main applications of PTFE type Teflon? Unlock Its Versatility for Your Industry

- What finishing techniques are effective for machined Teflon parts? Achieve Functional Performance and Dimensional Stability

- What are the unique properties of PTFE? Unlock Unmatched Performance in Demanding Applications

- What challenges arise when machining PTFE (Teflon)? Overcome Softness, Heat, and Instability

- What factors should be considered when choosing between Nylon and PTFE? Select the Right Material for Your Application