At its core, Polytetrafluoroethylene (PTFE) is widely used because it possesses a rare and powerful combination of four key properties that few other materials can offer in a single, cost-effective package: extreme chemical resistance, a vast operational temperature range, an incredibly low coefficient of friction, and excellent electrical insulation. This unique versatility makes it a reliable problem-solver for demanding applications across nearly every major industry.

The true value of PTFE isn't any single attribute, but its ability to simultaneously solve multiple, often conflicting, engineering challenges. It can safely contain the most corrosive acids while also providing a frictionless, non-stick surface, making it an indispensable high-performance polymer.

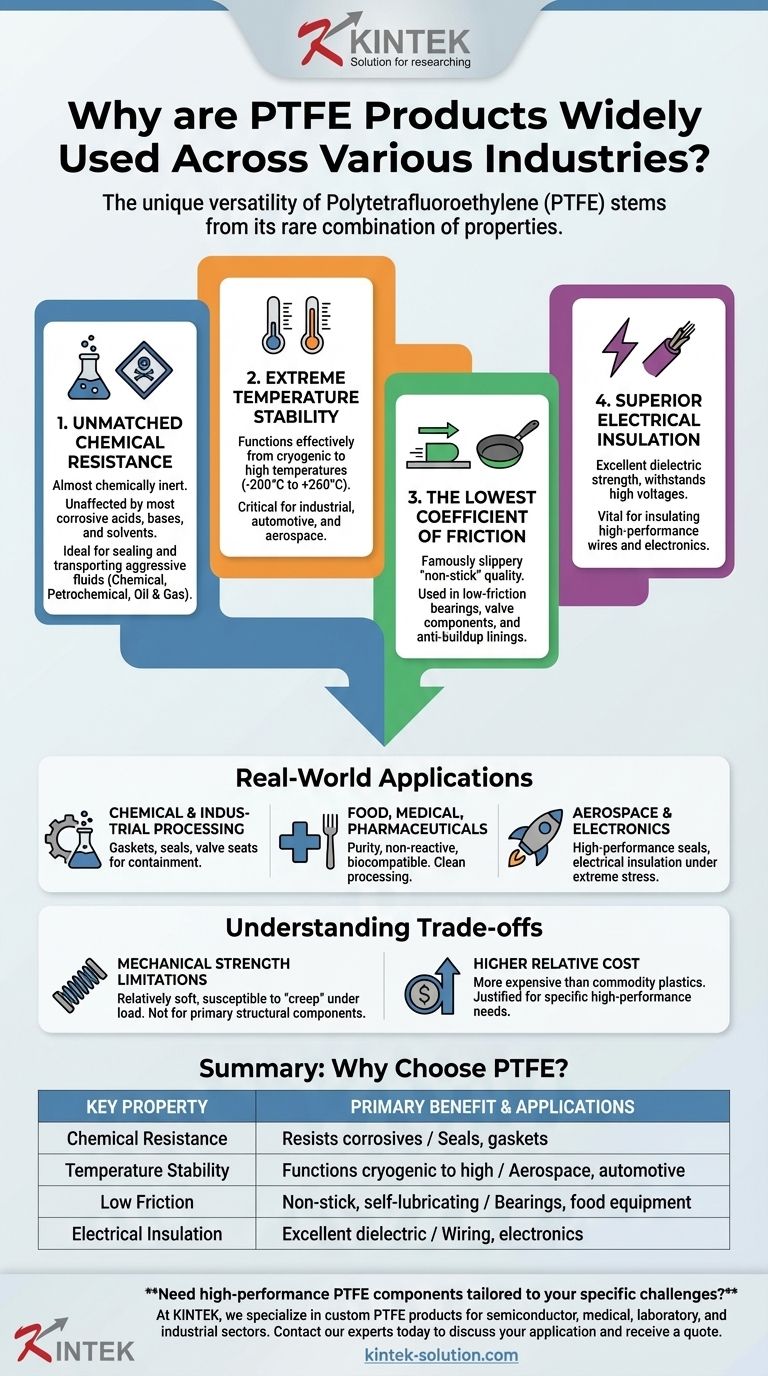

The Four Pillars of PTFE's Versatility

To understand why PTFE is so ubiquitous, we must look at the four fundamental properties that drive its adoption. These characteristics work in concert to deliver performance where other materials fail.

1. Unmatched Chemical Resistance

PTFE is almost completely chemically inert. It is unaffected by the vast majority of corrosive acids, bases, and solvents.

This makes it the default material for sealing and transporting aggressive fluids, especially in the chemical, petrochemical, and oil and gas industries.

2. Extreme Temperature Stability

PTFE products remain stable and functional over an exceptionally wide temperature range.

They can operate effectively in cryogenic conditions and at high temperatures, withstanding extremes that would cause other plastics to become brittle or melt. This is critical for industrial, automotive, and aerospace applications.

3. The Lowest Coefficient of Friction

PTFE has one of the lowest coefficients of friction of any known solid material, giving it its famously slippery or "non-stick" quality.

This property is leveraged not only in kitchenware but also in industrial settings for low-friction bearings, valve components, and linings that prevent material buildup.

4. Superior Electrical Insulation

PTFE is an excellent electrical insulator with high dielectric strength, meaning it can withstand high voltages without breaking down.

This, combined with its temperature resistance, makes it a vital component for insulating high-performance wires, cables, and sensitive electronic components.

How These Properties Translate to Real-World Applications

The theoretical benefits of PTFE become tangible in its practical uses. Each industry leverages a specific aspect of its unique profile.

In Chemical and Industrial Processing

The primary need here is containment. PTFE's chemical inertness and temperature range make it perfect for gaskets, seals, and valve seats.

These components reliably prevent leaks of hazardous liquids and gases, ensuring both safety and operational efficiency with minimal maintenance.

In Food, Medical, and Pharmaceuticals

In these regulated industries, purity is paramount. Because PTFE is non-reactive and non-toxic, it doesn't contaminate the products it touches.

Its non-stick surface also facilitates clean processing, while its biocompatibility allows for its use in medical equipment and even implants.

In Aerospace and Electronics

Performance under stress is the key driver in these fields. PTFE is used for high-performance seals that must function in extreme temperatures and pressures.

Its electrical insulation properties are critical for protecting wiring and electronics in compact, high-heat environments.

Understanding the Trade-offs

Despite its remarkable advantages, PTFE is not a universal solution. Being an objective advisor means acknowledging its limitations.

Mechanical Strength Limitations

Compared to metals or engineered plastics, PTFE is a relatively soft material. It can be susceptible to "creep," or deformation under a sustained high load.

This means it is not typically used for primary structural components that require high rigidity or tensile strength.

Higher Relative Cost

While often described as cost-effective for its performance, PTFE is more expensive than common commodity plastics like polyethylene or polypropylene.

Its use is justified when its specific high-performance properties are a requirement, not a preference.

Making the Right Choice for Your Application

Selecting the right material depends entirely on the problem you need to solve. PTFE becomes the leading candidate when your requirements are demanding and specific.

- If your primary focus is sealing corrosive chemicals or gases: PTFE's unrivaled chemical inertness makes it the safest and most reliable choice for gaskets, packings, and valve linings.

- If your primary focus is reducing friction or creating non-stick surfaces: Its exceptionally low coefficient of friction is ideal for self-lubricating bearings, industrial coatings, and food-grade equipment.

- If your primary focus is electrical insulation in harsh environments: Its combination of high dielectric strength and broad temperature stability provides dependable performance for critical wiring and components.

Ultimately, PTFE's widespread adoption stems from its unique ability to solve engineering challenges that other materials simply cannot address.

Summary Table:

| Key Property | Primary Benefit | Common Applications |

|---|---|---|

| Chemical Resistance | Resists corrosive acids, bases, and solvents | Seals, gaskets, liners in chemical processing |

| Temperature Stability | Functions from cryogenic to high temperatures | Aerospace, automotive, and industrial components |

| Low Friction | Provides non-stick, self-lubricating surfaces | Bearings, labware, food processing equipment |

| Electrical Insulation | Excellent dielectric strength for high voltages | Wiring, cables, and electronic components |

Need high-performance PTFE components tailored to your specific challenges?

At KINTEK, we specialize in the precision manufacturing of custom PTFE products—from seals and liners to complex labware—for the semiconductor, medical, laboratory, and industrial sectors. Whether you require prototypes or high-volume orders, our expertise ensures you get components that leverage PTFE's full potential to solve your most demanding engineering problems.

Contact our experts today to discuss your application and receive a quote.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Customizable PTFE Rods for Advanced Industrial Applications

- Custom PTFE Volumetric Flasks for Advanced Scientific and Industrial Use

- Custom PTFE Teflon Balls for Advanced Industrial Applications

People Also Ask

- What properties make Teflon ideal for medical applications? Discover Its Critical Role in Safety & Performance

- What are the benefits of PTFE's chemical resistance? Achieve Unmatched Reliability in Corrosive Environments

- What is the chemical composition and structure of PTFE? Unlocking the Secrets of Teflon's Power

- What is the role of polypropylene netting in PTFE laminated membrane filters? Ensuring Durability and Performance

- What factors should be considered when choosing between PTFE and FR4 PCB materials? Optimize Your Design for Performance and Cost.

- What is PTFE, and why are alternatives being sought? Navigating the Shift from 'Forever Chemicals'

- What are the benefits of carbon-filled PTFE? Enhance Strength, Wear & Conductivity

- What is the hardness of PTFE on the Shore scale? A Guide to Its Softness and Performance