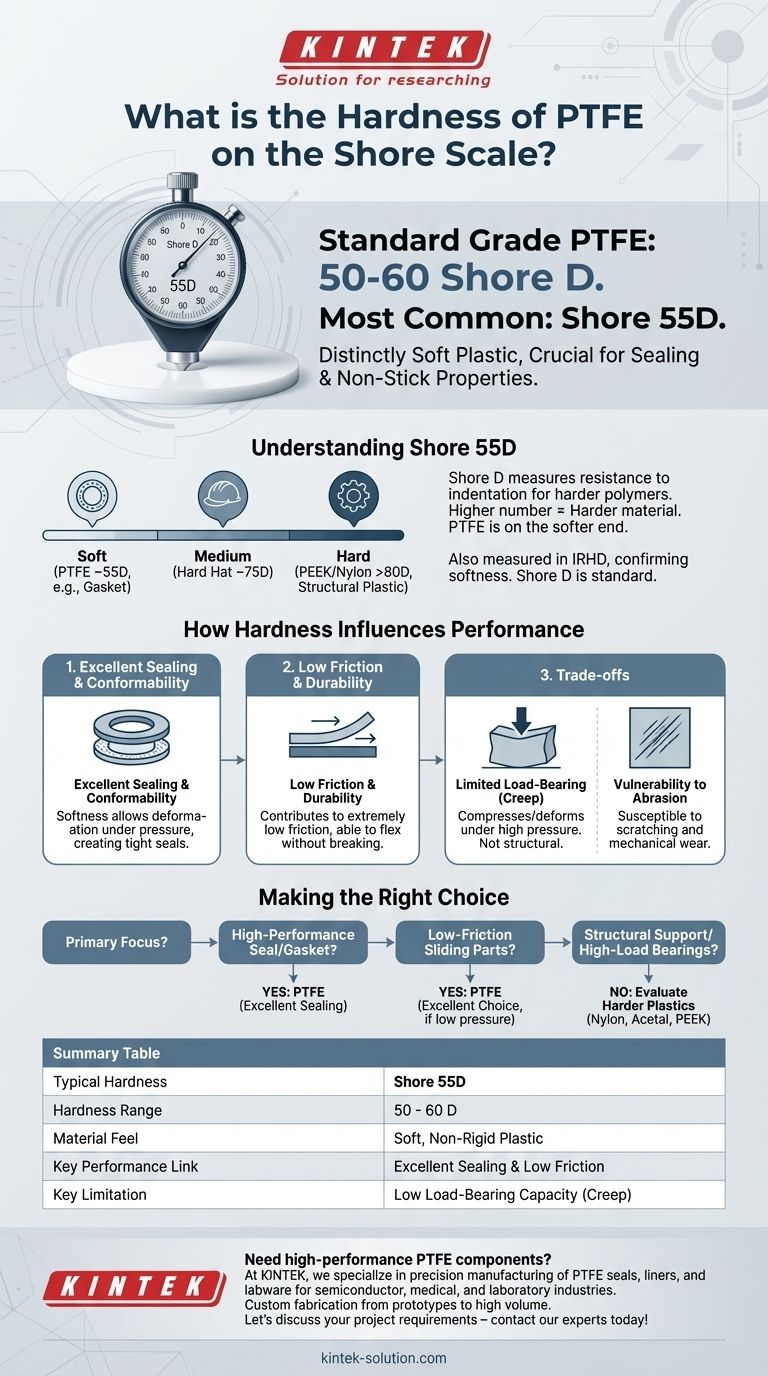

For a standard grade of Polytetrafluoroethylene (PTFE), the hardness is consistently rated between 50 and 60 on the Shore D durometer scale. The most commonly cited value for this versatile fluoropolymer is Shore 55D.

While the number itself is straightforward, its real importance lies in what it tells you: PTFE is a distinctly soft plastic. This softness is not a weakness but is fundamental to its most valued properties, such as its excellent sealing ability and unparalleled non-stick surface.

What "Shore 55D" Actually Means

To understand if PTFE is the right material for your application, you need to place its hardness value in the proper context. It defines how the material behaves under load and in contact with other surfaces.

The Shore D Scale Explained

The Shore durometer scale measures the resistance of a material to indentation. The "D" scale is specifically used for harder polymers, ranging from rigid rubbers to semi-rigid and hard plastics. A higher number indicates a harder material.

How PTFE Compares to Other Materials

A rating of 55D places PTFE firmly on the softer end of the engineering plastics spectrum.

For comparison, a hard hat is typically around 75D, and a very hard structural plastic like PEEK or Nylon can easily exceed 80D. This highlights that PTFE is not designed to be a rigid, structural material.

A Note on Other Hardness Scales

You may occasionally see PTFE's hardness listed on other scales, such as IRHD (International Rubber Hardness Degrees). While the measurement principles differ, the conclusion is the same: PTFE is a relatively soft material compared to other engineering plastics. The Shore D scale remains the most common industry standard for this type of polymer.

How Hardness Influences PTFE's Performance

PTFE's relatively low hardness is directly responsible for some of its most powerful engineering characteristics. It is a feature, not a bug.

The Link to Sealing and Conformability

Because it is soft, PTFE can easily deform under pressure. This allows it to conform perfectly to the irregularities of mating surfaces, creating an exceptionally tight and reliable seal in gaskets and O-rings.

Impact on Friction and Durability

The material's softness contributes to its extremely low coefficient of friction. Rather than resisting an object with unyielding rigidity, its surface has enough give to minimize frictional forces. Combined with its high flexural strength, this means PTFE can bend and flex repeatedly without breaking.

Understanding the Trade-offs

The benefits of PTFE's softness come with clear limitations that are critical to recognize for successful application design.

Limited Load-Bearing Capacity

PTFE is not suitable for high-load structural components. Its softness means it will compress and deform under significant pressure, a property known as creep or cold flow. The references note a compression strength of just 5 MPa at 1% deformation.

Vulnerability to Abrasion

Softer materials are more susceptible to scratching and mechanical wear than harder ones. While PTFE is highly durable in low-friction sliding applications, it can be easily damaged by abrasive particles or sharp edges.

Making the Right Choice for Your Application

Selecting the correct material requires matching its properties to the primary demands of the task.

- If your primary focus is creating a high-performance seal or gasket: PTFE's softness is a significant advantage, allowing it to conform perfectly to prevent leaks.

- If your primary focus is a low-friction surface for sliding parts: PTFE is an excellent choice, provided the contact pressures are not excessively high.

- If your primary focus is structural support or high-load bearings: You should evaluate harder plastics like Nylon, Acetal, or PEEK, as PTFE will deform under these conditions.

Understanding PTFE's specific hardness is the key to leveraging its unique combination of properties for the right engineering challenge.

Summary Table:

| Property | Value / Description |

|---|---|

| Typical Hardness (Shore D) | 55D |

| Hardness Range | 50 - 60 D |

| Material Feel | Soft, Non-Rigid Plastic |

| Key Performance Link | Excellent Sealing & Low Friction |

| Key Limitation | Low Load-Bearing Capacity (Creep) |

Need high-performance PTFE components that leverage this unique softness?

At KINTEK, we specialize in precision manufacturing of PTFE seals, liners, and labware. Our expertise ensures your parts perfectly balance PTFE's superior sealing and non-stick properties with the dimensional stability required for demanding applications in the semiconductor, medical, and laboratory industries.

We offer custom fabrication from prototypes to high-volume orders. Let's discuss your project requirements – contact our experts today!

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Customizable PTFE Rods for Advanced Industrial Applications

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Custom PTFE Square Trays for Industrial and Laboratory Use

People Also Ask

- How was Teflon discovered and what was its initial use? From Lab Accident to Wartime Innovation

- What is PTFE and how was it discovered? The Accidental Invention of Teflon

- What happens when PTFE is incinerated? The Hidden PFAS Pollution Risk

- What are some alternatives to Teflon/PTFE? Explore High-Performance Polymers for Your Application

- What are the key structural components of Teflon? Unlocking the Secrets of PTFE's Performance

- What should consumers be cautious about regarding PTFE? The Hidden Risks of 'Forever Chemicals'

- What are the key characteristics of PTFE? A Guide to Its Extreme Performance

- How does PTFE benefit the semiconductor industry? Essential for High-Purity Chip Fabrication