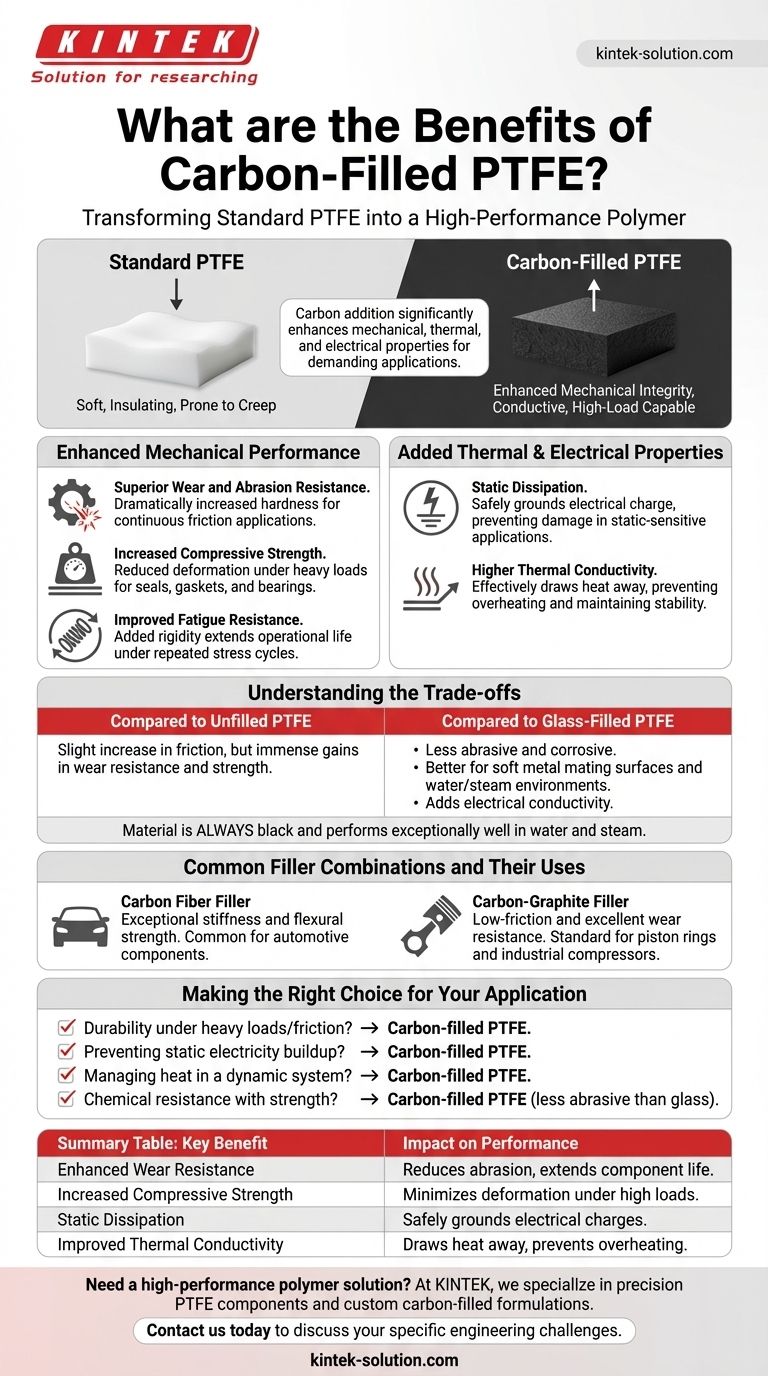

The primary benefit of carbon-filled PTFE is the significant enhancement of its mechanical, thermal, and electrical properties. By adding carbon as a filler, standard PTFE is transformed from a soft, insulating material into a high-performance polymer with superior compressive strength, wear resistance, and the ability to dissipate both static electricity and heat.

Adding carbon to PTFE fundamentally enhances its mechanical integrity and adds crucial thermal and electrical conductivity. This makes it a superior material for high-load, high-wear, and static-sensitive applications where unfilled PTFE would quickly fail.

Enhanced Mechanical Performance

Unfilled PTFE is known for its softness and tendency to deform under pressure, a phenomenon known as "creep." The addition of carbon filler directly addresses these weaknesses, creating a much more robust material.

Superior Wear and Abrasion Resistance

Carbon dramatically increases the hardness and durability of the PTFE matrix. This results in excellent resistance to wear, making it ideal for dynamic components that experience continuous friction.

Increased Compressive Strength

Carbon-filled PTFE exhibits significantly reduced deformation under heavy loads. It can withstand higher pressures without losing its shape, a critical property for seals, gaskets, and bearings.

Improved Fatigue Resistance

Components subjected to repeated stress cycles benefit from the added rigidity that carbon provides. This enhancement in fatigue resistance extends the operational life of parts in demanding industrial machinery.

Added Thermal and Electrical Properties

Perhaps the most significant transformation is the addition of conductive properties to PTFE, which is naturally an excellent insulator.

Static Dissipation

In applications involving high-speed movement or the flow of certain materials, a static electrical charge can build up on component surfaces. Carbon-filled PTFE is static dissipative, safely grounding this charge and preventing electrical discharge that could damage sensitive electronics or create a safety hazard.

Higher Thermal Conductivity

Friction generates heat. Carbon-filled PTFE can draw heat away from mating surfaces much more effectively than standard PTFE. This improved thermal conductivity prevents overheating, maintains dimensional stability, and extends the life of the component and the system.

Understanding the Trade-offs

While carbon-filled PTFE offers substantial benefits, it's important to understand its specific characteristics compared to other options.

Compared to Unfilled PTFE

The primary trade-off is a slight increase in the coefficient of friction compared to virgin PTFE. However, the immense gains in wear resistance and strength almost always outweigh this minor change in high-load applications.

Compared to Glass-Filled PTFE

Carbon is less abrasive and corrosive than glass fillers. This makes it a better choice for applications involving soft metal mating surfaces or for use in water and steam environments where glass can be detrimental. Unlike glass, carbon adds electrical conductivity.

Material Characteristics

Carbon-filled PTFE is always black in color due to the filler. It also performs exceptionally well in applications involving water or steam, where some other fillers may struggle.

Common Filler Combinations and Their Uses

The type of carbon used can be tailored to specific application requirements, further enhancing performance.

Carbon Fiber Filler

Using carbon in fiber form provides the greatest improvement in mechanical properties. It creates a composite with exceptional stiffness, flexural strength, and load-bearing capabilities, making it a common choice for automotive components.

Carbon-Graphite Filler

This blend combines the structural benefits of carbon with the self-lubricating properties of graphite. This results in an extremely low-friction material with excellent wear resistance, making it the standard for piston rings, rider rings, and rod packings in industrial compressors.

Making the Right Choice for Your Application

Selecting the correct material depends entirely on the primary challenge you need to solve.

- If your primary focus is durability under heavy loads or constant friction: Carbon-filled PTFE offers superior compressive strength and wear resistance for components like seals, bearings, and piston rings.

- If your primary focus is preventing static electricity buildup: The electrical conductivity of carbon-filled PTFE makes it the definitive choice where static discharge could damage electronics or pose a safety risk.

- If your primary focus is managing heat in a dynamic system: Carbon's enhanced thermal conductivity helps draw heat away from critical surfaces, improving performance and component lifespan.

- If you need chemical resistance combined with strength for soft mating surfaces: Carbon-filled PTFE is less abrasive than glass-filled alternatives and performs exceptionally well in water or steam applications.

Ultimately, choosing carbon-filled PTFE is a strategic decision to overcome the inherent physical limitations of standard PTFE in demanding environments.

Summary Table:

| Key Benefit | Impact on Performance |

|---|---|

| Enhanced Wear Resistance | Reduces abrasion and extends component life in dynamic applications. |

| Increased Compressive Strength | Minimizes deformation under high loads for seals and bearings. |

| Static Dissipation | Safely grounds electrical charges, protecting sensitive electronics. |

| Improved Thermal Conductivity | Draws heat away from surfaces, preventing overheating. |

Need a high-performance polymer solution for your demanding application?

At KINTEK, we specialize in manufacturing precision PTFE components, including custom carbon-filled formulations. Whether you're in the semiconductor, medical, laboratory, or industrial sector, our expertise ensures your parts meet exact specifications for strength, wear resistance, and conductivity—from prototypes to high-volume orders.

Contact us today to discuss how our carbon-filled PTFE can solve your specific engineering challenges.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Bottles for Diverse Industrial Applications

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Custom Machined Molded PTFE Teflon Parts Manufacturer for Laboratory ITO FTO Conductive Glass Cleaning Flower Basket

People Also Ask

- What are the unique properties of PTFE? Unlock Unmatched Performance in Demanding Applications

- What design considerations are important for custom PTFE parts? Design for Performance & Reliability

- What factors should be considered when choosing between Nylon and PTFE? Select the Right Material for Your Application

- What industrial benefits do PTFE-machined parts offer? Achieve Peak Performance in Demanding Applications

- What chemical processing applications involve PTFE-machined parts? Essential Components for Corrosive & High-Purity Systems