In the medical field, material selection is a matter of safety and performance. Teflon, or Polytetrafluoroethylene (PTFE), is considered ideal for medical applications due to a unique combination of properties: it is highly biocompatible and chemically inert, possesses an extremely low coefficient of friction, and can withstand the harsh chemicals and high temperatures required for sterilization.

The core reason for Teflon's value in medicine is its profound inertness. It is one of the few materials that can be placed in contact with the human body or sensitive fluids with virtually no risk of chemical reaction, while also providing the physical durability and performance needed for demanding clinical environments.

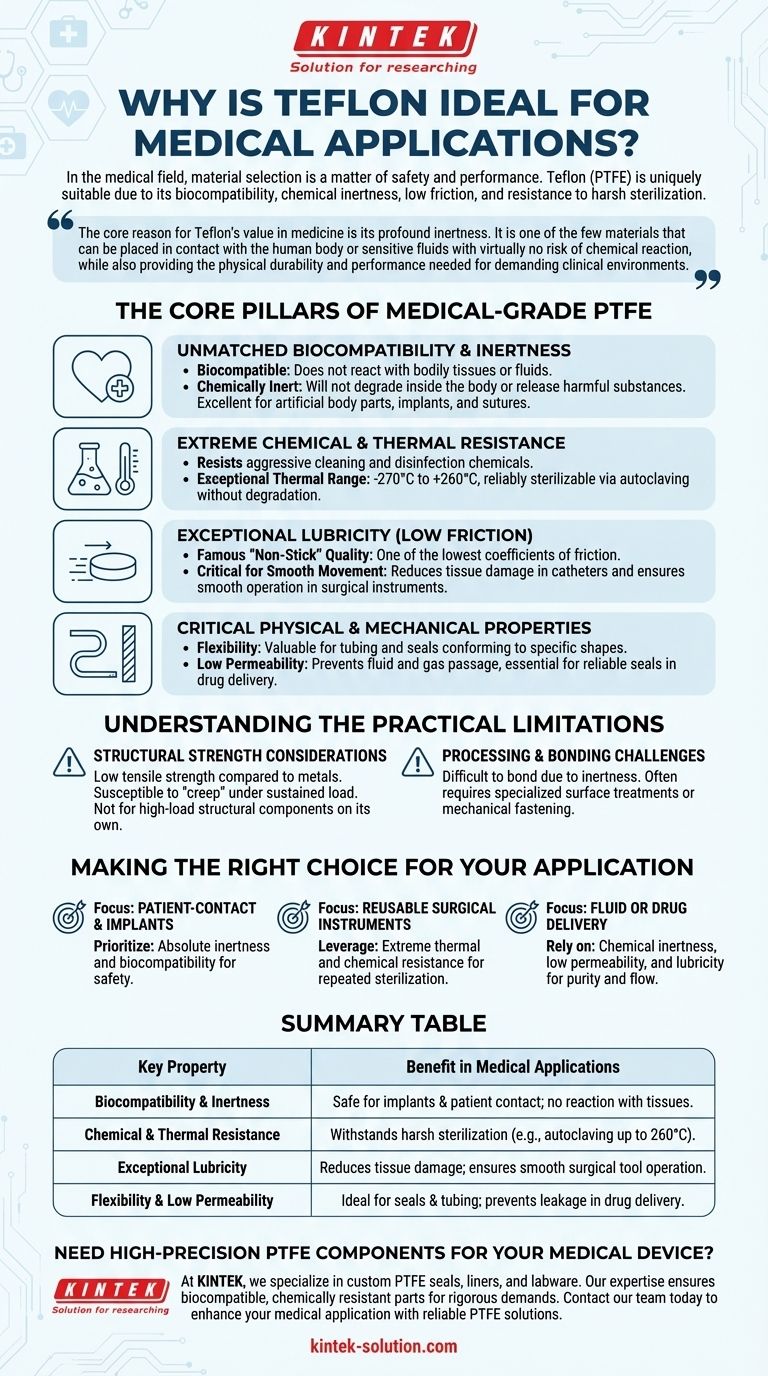

The Core Pillars of Medical-Grade PTFE

To understand why PTFE is a trusted material for everything from implants to surgical tools, we must break down its fundamental characteristics. These properties work in concert to ensure both patient safety and device reliability.

Unmatched Biocompatibility and Inertness

The single most important feature of medical-grade PTFE is its biocompatibility. This means it does not react with bodily tissues or fluids.

Because it is chemically inert, the material will not degrade inside the body, nor will it release harmful substances. This makes it an excellent choice for artificial body parts, implants, and sutures.

Extreme Chemical and Thermal Resistance

Medical devices, especially reusable ones, must endure rigorous sterilization processes. PTFE excels in this environment.

It is resistant to the aggressive chemicals used for cleaning and disinfection. Furthermore, it has an exceptional working thermal range, from -270°C to +260°C, allowing it to be reliably sterilized using methods like autoclaving without degrading.

Exceptional Lubricity (Low Friction)

PTFE has one of the lowest coefficients of friction of any solid material, giving it its famous non-stick quality.

This lubricity is critical for devices that must move with minimal resistance. In catheters, for instance, it reduces friction against blood vessels, minimizing tissue damage. In surgical instruments, it ensures smooth, predictable operation.

Critical Physical and Mechanical Properties

Beyond its chemical stability, PTFE offers key physical attributes. Its flexibility is valuable for applications like tubing and seals that must conform to specific shapes.

It also has very low permeability, preventing fluids and gases from passing through it. This is essential for creating reliable seals and ensuring the purity of contents in drug delivery and fluid handling systems.

Understanding the Practical Limitations

While its properties are exceptional, PTFE is not a universal solution. An objective evaluation requires acknowledging its trade-offs in engineering design.

Structural Strength Considerations

Compared to metals or other high-performance polymers, PTFE has relatively low tensile strength and is susceptible to "creep" under sustained load.

This means it is not typically suitable for high-load, structural components on its own. It is most often used as a coating, liner, or component where its surface and chemical properties are paramount.

Processing and Bonding Challenges

The same chemical inertness that makes PTFE so valuable also makes it very difficult to bond to other materials using conventional adhesives.

Specialized surface treatments or mechanical fastening methods are often required, which can add complexity and cost to the manufacturing process.

Making the Right Choice for Your Application

Selecting the right material depends entirely on the primary goal of the medical device. PTFE's properties should be matched to the specific demands of the application.

- If your primary focus is patient-contact and implants: Prioritize PTFE for its absolute inertness and biocompatibility, which minimizes the risk of adverse biological reactions.

- If your primary focus is reusable surgical instruments: Leverage PTFE's extreme thermal and chemical resistance to ensure the device can withstand repeated, harsh sterilization cycles.

- If your primary focus is fluid or drug delivery: Rely on its chemical inertness, low permeability, and lubricity to maintain purity and ensure smooth, efficient flow.

Ultimately, Teflon's unique synthesis of safety and stability makes it an indispensable material for advancing modern medical technology.

Summary Table:

| Key Property | Benefit in Medical Applications |

|---|---|

| Biocompatibility & Inertness | Safe for implants and patient contact; no reaction with tissues or fluids. |

| Chemical & Thermal Resistance | Withstands harsh sterilization (e.g., autoclaving up to 260°C) without degrading. |

| Exceptional Lubricity (Low Friction) | Reduces tissue damage in catheters; ensures smooth operation of surgical tools. |

| Flexibility & Low Permeability | Ideal for seals and tubing; prevents fluid/gas leakage in drug delivery systems. |

Need high-precision PTFE components for your medical device? At KINTEK, we specialize in manufacturing custom PTFE seals, liners, labware, and more for the medical, semiconductor, and laboratory industries. Our expertise ensures biocompatible, chemically resistant parts that meet rigorous sterilization demands—from prototypes to high-volume orders. Contact our team today to discuss how we can enhance your medical application with reliable PTFE solutions.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Custom PTFE Square Trays for Industrial and Laboratory Use

People Also Ask

- What are the key advantages of PTFE? Unmatched Performance for Extreme Environments

- Why is PTFE rod suitable for automotive applications? Boost Vehicle Performance & Durability

- What are the key considerations when machining Teflon? Master Precision Machining for Soft Polymers

- What are the main advantages of using PTFE parts in industrial applications? Unlock Unmatched Chemical Resistance and Reliability

- What are the best practices for achieving tight tolerances in Teflon (PTFE) machining? Master Precision for Demanding Applications