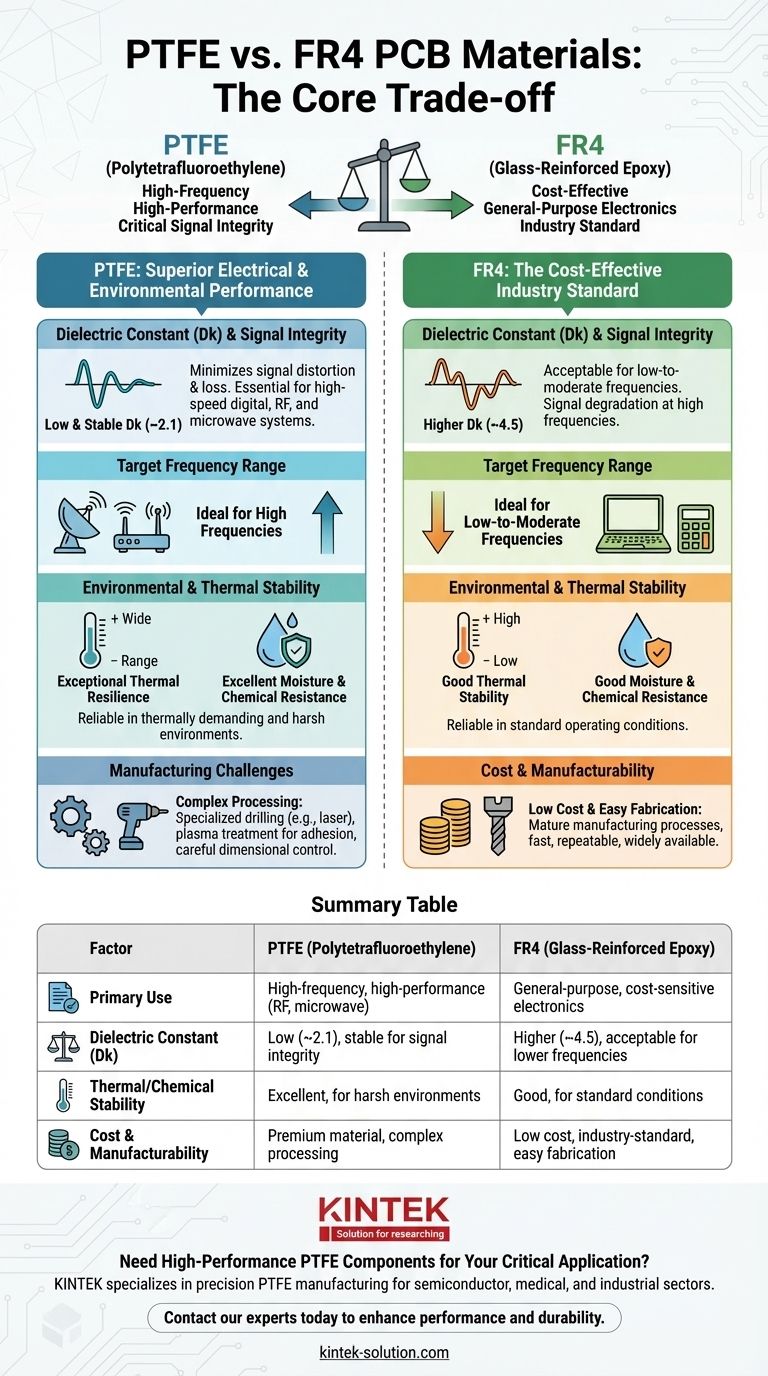

When choosing a PCB material, the decision between PTFE and FR4 comes down to a fundamental trade-off. PTFE (Polytetrafluoroethylene) is essential for high-frequency, high-performance applications where signal integrity is critical, while FR4 is the cost-effective industry standard for a vast majority of general-purpose electronics. The right choice depends entirely on your specific frequency, performance, and budgetary requirements.

Choosing the wrong PCB material can either cripple your circuit's performance with signal loss or inflate your project's budget unnecessarily. FR4 is the default choice for its versatility and low cost, but for high-frequency applications, the superior electrical properties of PTFE are non-negotiable.

The Core Difference: Electrical Performance

The primary reason to select one material over the other lies in how they handle electrical signals, especially as frequencies increase.

Dielectric Constant (Dk) and Signal Integrity

The most critical electrical property is the dielectric constant (Dk). It measures a material's ability to store electrical energy.

PTFE has a very low and stable Dk, typically around 2.1. This low value minimizes signal distortion and loss, allowing electrical signals to travel faster and with greater fidelity, which is paramount for high-frequency circuits.

FR4, a glass-reinforced epoxy laminate, has a higher Dk, often around 4.5. This is perfectly acceptable for many applications but can lead to significant signal degradation at radio frequencies (RF) and microwave frequencies.

Target Frequency Range

Because of its low Dk, PTFE is the material of choice for high-speed digital circuits, RF applications, and microwave systems.

Conversely, FR4 is ideal for low-to-moderate frequency applications, including most consumer electronics, industrial controls, and computing peripherals. It provides reliable performance where signal integrity demands are less extreme.

Environmental and Thermal Stability

Beyond electrical performance, the operating environment plays a crucial role in material selection.

Thermal Resilience

PTFE exhibits exceptional thermal stability, maintaining its structural and electrical properties across a wider range of temperatures than FR4. This makes it a more reliable choice for applications that generate significant heat or operate in thermally demanding environments.

Moisture and Chemical Resistance

PTFE is chemically inert and has extremely low moisture absorption. This makes it highly resistant to degradation in humid or corrosive environments, ensuring long-term reliability for critical systems in aerospace, defense, or industrial settings.

Understanding the Trade-offs: Cost and Manufacturability

Performance benefits rarely come without costs, both in material price and manufacturing complexity.

The Cost Factor

This is the most straightforward trade-off. FR4 is significantly less expensive than PTFE. Its low cost and wide availability make it the default for nearly all cost-sensitive projects.

PTFE is a premium material, and its higher raw material cost is a primary consideration. Using it where it isn't strictly necessary is a common source of budget overruns.

The Manufacturing Challenge

FR4 is the industry standard for a reason: it's easy to work with. Decades of process optimization have made manufacturing FR4 boards simple, fast, and repeatable.

PTFE, however, presents unique challenges. Its softness makes it prone to surface damage and requires specialized drilling techniques, such as high-resolution laser drilling, to achieve clean holes.

Specialized PTFE Processing

Achieving strong copper adhesion on PTFE's slick surface requires additional steps like plasma treatment. Furthermore, its dimensional stability during lamination must be carefully controlled with high-temperature processes to prevent warping, adding complexity and cost to the manufacturing cycle.

Making the Right Choice for Your Application

Ultimately, your selection should be a deliberate decision based on the specific goals of your project.

- If your primary focus is high-frequency performance (RF, microwave, high-speed digital): PTFE is the necessary choice to ensure signal integrity and minimize loss.

- If your primary focus is cost-sensitive, general-purpose electronics: FR4 is the industry standard, offering the best balance of performance, cost, and manufacturability.

- If your application operates in extreme temperatures or harsh chemical environments: PTFE's superior thermal and chemical resistance makes it the more reliable option.

- If you need rapid prototyping and standard manufacturing processes: FR4's wide availability and ease of fabrication provide a significant advantage.

By aligning your material choice with your specific performance, environmental, and budgetary requirements, you ensure both the technical success and economic efficiency of your project.

Summary Table:

| Factor | PTFE (Polytetrafluoroethylene) | FR4 (Glass-Reinforced Epoxy) |

|---|---|---|

| Primary Use | High-frequency, high-performance (RF, microwave) | General-purpose, cost-sensitive electronics |

| Dielectric Constant (Dk) | Low (~2.1), stable for signal integrity | Higher (~4.5), acceptable for lower frequencies |

| Thermal/Chemical Stability | Excellent, for harsh environments | Good, for standard conditions |

| Cost & Manufacturability | Premium material, complex processing | Low cost, industry-standard, easy fabrication |

Need High-Performance PTFE Components for Your Critical Application?

KINTEK specializes in the precision manufacturing of PTFE components—including seals, liners, and custom labware—for the semiconductor, medical, and industrial sectors. We understand the material challenges you face and provide custom fabrication from prototypes to high-volume orders to ensure your project's success and reliability.

Contact our experts today to discuss how our PTFE solutions can enhance your product's performance and durability.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Customizable PTFE Rods for Advanced Industrial Applications

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

People Also Ask

- What are the key advantages of PTFE? Unmatched Performance for Extreme Environments

- What are the best practices for achieving tight tolerances in Teflon (PTFE) machining? Master Precision for Demanding Applications

- What are the main advantages of using PTFE parts in industrial applications? Unlock Unmatched Chemical Resistance and Reliability

- What industries use PTFE machined parts and for what applications? Critical Components for Demanding Environments

- How does PTFE contribute to low friction and wear resistance? Achieve Superior Performance with Advanced Materials