In PTFE laminated membrane filters, polypropylene netting serves a single, critical purpose: to act as a structural support layer. This lamination transforms the inherently fragile Polytetrafluoroethylene (PTFE) membrane into a robust, easy-to-handle disc, enabling its practical use in filter holders.

The polypropylene netting’s role is not chemical but purely mechanical. It adds the necessary strength and rigidity to a high-performance PTFE membrane, making an otherwise delicate material durable enough for demanding filtration and venting applications.

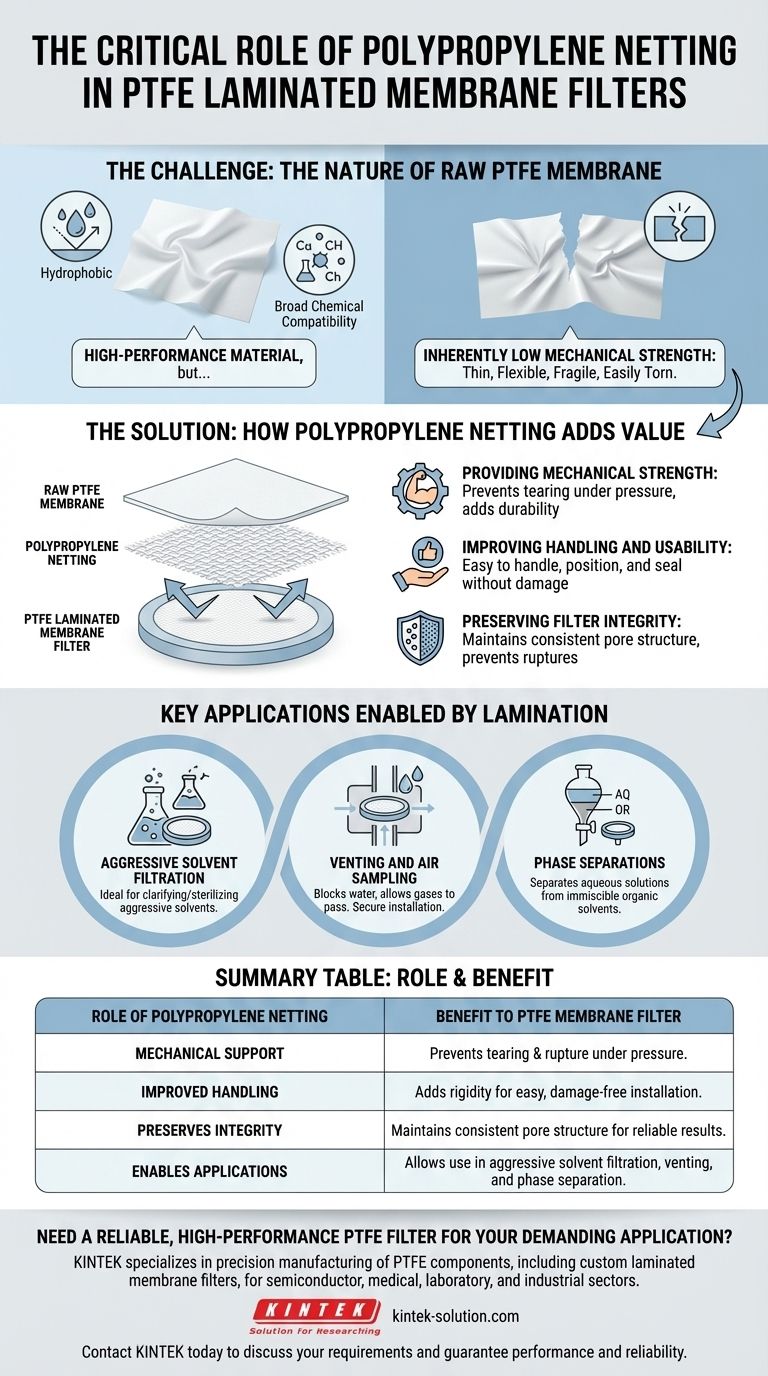

The Challenge: The Nature of Raw PTFE Membrane

To understand why the polypropylene support is necessary, we must first look at the properties of the PTFE membrane itself.

### A High-Performance Material

PTFE is an exceptional material for filtration due to its unique properties. It is hydrophobic, meaning it repels water, and possesses broad chemical compatibility, making it resistant to nearly all solvents and aggressive chemicals.

### Inherently Low Mechanical Strength

Despite its chemical resilience, a pure PTFE membrane is mechanically weak. It is thin, flexible, and can be easily torn, stretched, or wrinkled during handling and installation, compromising the integrity of the filtration process.

The Solution: How Polypropylene Netting Adds Value

The polypropylene netting is laminated directly onto the PTFE membrane to overcome its physical limitations, providing several key advantages.

### Providing Mechanical Strength

The primary benefit is a significant increase in durability. The netting prevents the membrane from tearing under pressure or during assembly into a filter holder.

### Improving Handling and Usability

The added rigidity makes the filter disc much easier to work with. It can be picked up, positioned, and sealed into a holder without the risk of accidental damage, ensuring a reliable and convenient user experience.

### Preserving Filter Integrity

By supporting the membrane, the netting ensures that the filter's pore structure remains consistent and that no ruptures occur during operation. This is essential for achieving accurate and repeatable results in sensitive applications.

Key Applications Enabled by Lamination

The combination of PTFE's chemical properties and polypropylene's structural support makes these laminated filters ideal for specific tasks where other materials would fail.

### Aggressive Solvent Filtration

The filter’s broad chemical compatibility and physical strength make it perfect for clarifying or sterilizing aggressive solvents that would degrade other membrane types.

### Venting and Air Sampling

Because PTFE is hydrophobic, it effectively blocks water droplets while allowing gasses to pass through freely. The netting ensures the vent can be installed securely and withstand pressure differentials without failing.

### Phase Separations

The water-repellent nature of the PTFE membrane is used to separate aqueous solutions from immiscible organic solvents. The polypropylene support provides the durability required for this process.

Making the Right Choice for Your Application

Understanding this composite structure helps you leverage its strengths effectively.

- If your primary focus is aggressive solvent filtration: The laminated structure ensures the filter can withstand both chemical attack and system pressure without rupturing.

- If your primary focus is sterile venting: The improved handling guarantees a secure, damage-free installation, maintaining the integrity of your sterile barrier.

- If your primary focus is separating aqueous and organic phases: The robust design provides a reliable physical barrier that will not fail during the separation process.

By recognizing the distinct roles of the PTFE membrane and its polypropylene support, you can confidently select the correct filter to achieve reliable, repeatable results.

Summary Table:

| Role of Polypropylene Netting | Benefit to PTFE Membrane Filter |

|---|---|

| Mechanical Support | Prevents tearing and rupture under pressure. |

| Improved Handling | Adds rigidity for easy, damage-free installation. |

| Preserves Integrity | Maintains consistent pore structure for reliable results. |

| Enables Applications | Allows use in aggressive solvent filtration, venting, and phase separation. |

Need a reliable, high-performance PTFE filter for your demanding application?

KINTEK specializes in the precision manufacturing of PTFE components, including custom laminated membrane filters. We understand that your processes in the semiconductor, medical, laboratory, and industrial sectors require filters that combine superior chemical resistance with unwavering mechanical strength.

Our expertise ensures that your filters are not only chemically compatible but also durable enough to handle installation and operational pressures without failure. From prototypes to high-volume orders, we deliver solutions you can trust for critical filtration, venting, and separation tasks.

Contact KINTEK today to discuss your specific requirements and let our experts provide a solution that guarantees performance and reliability.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- PTFE Chemical Solvent Sampling Spoon

- Customizable PTFE Seals Filter Holders for Versatile Applications

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

People Also Ask

- What design considerations are important for custom PTFE parts? Design for Performance & Reliability

- What are the unique properties of PTFE? The 3 Pillars Driving Demand for High-Performance Parts

- What are the unique properties of PTFE? Unlock Unmatched Performance in Demanding Applications

- What factors should be considered when choosing between Nylon and PTFE? Select the Right Material for Your Application

- What are the main applications of PTFE type Teflon? Unlock Its Versatility for Your Industry