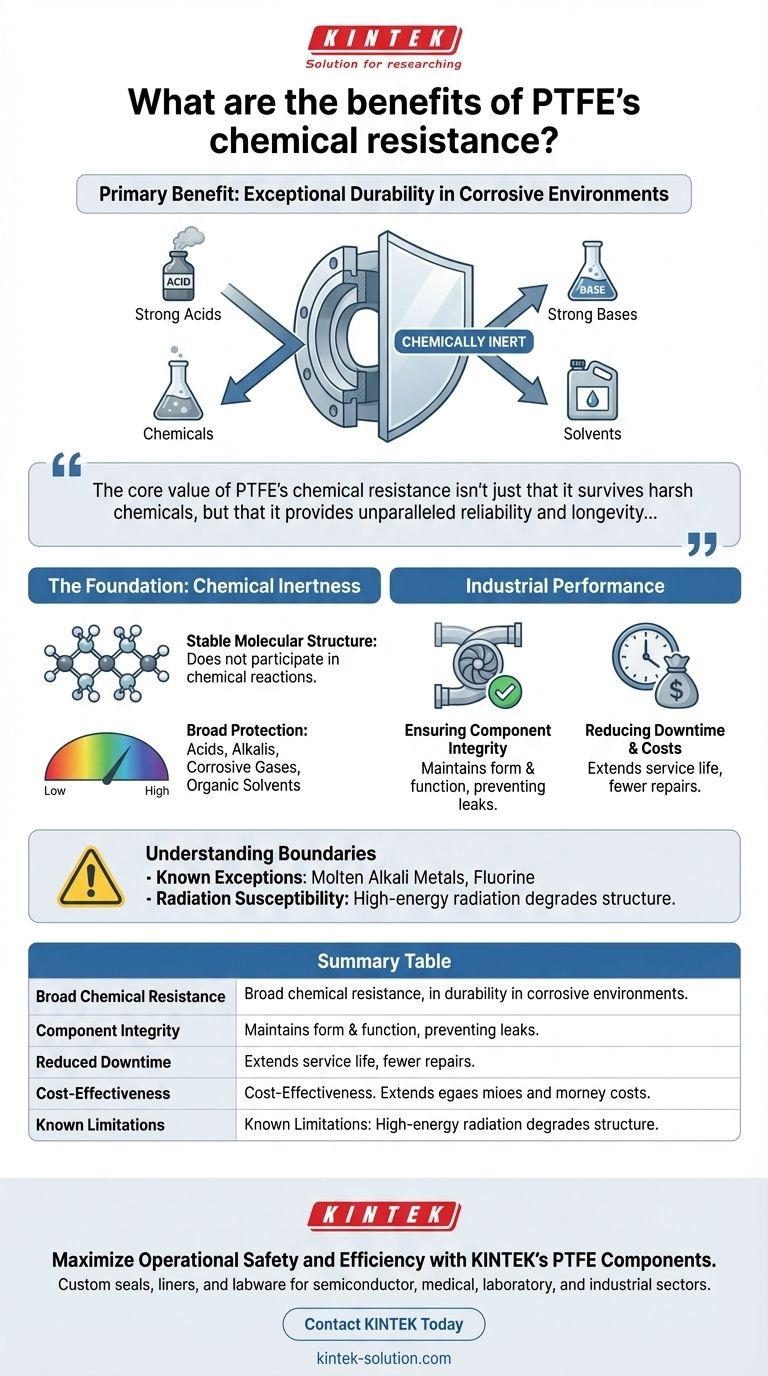

The primary benefit of PTFE's chemical resistance is its exceptional durability in corrosive environments. Because PTFE is chemically inert, it does not react with or degrade when exposed to nearly all industrial chemicals, including strong acids, bases, and solvents. This ensures components maintain their structural integrity, significantly reducing equipment failure, downtime, and long-term replacement costs.

The core value of PTFE's chemical resistance isn't just that it survives harsh chemicals, but that it provides unparalleled reliability and longevity in applications where other materials would quickly fail. This translates directly to safer, more cost-effective operations.

The Foundation of PTFE's Resilience: Chemical Inertness

What "Chemically Inert" Means

Polytetrafluoroethylene (PTFE) is one of the most chemically resistant plastics known to science.

Its molecular structure is incredibly stable, making it almost completely inert. This means it does not participate in chemical reactions with substances it comes into contact with.

Think of it as a perfect shield at a molecular level; corrosive agents simply have nothing to react with on the PTFE surface.

A Broad Spectrum of Protection

This inert nature gives PTFE an impressively broad resistance profile.

It remains unaffected by the vast majority of aggressive chemicals used in industrial settings, including strong acids, alkalis, corrosive gases, and organic solvents.

Remarkably, there are no known solvents that can dissolve PTFE at room temperature, a testament to its unique stability.

How Chemical Resistance Translates to Industrial Performance

Ensuring Component Integrity

In applications like pipelines, washers, or impellers, exposure to aggressive chemicals can cause other materials to corrode, swell, or break down.

PTFE's resistance ensures these components maintain their physical form and function even after prolonged and repeated exposure.

This prevents leaks, contamination, and catastrophic equipment failure.

Reducing Downtime and Costs

When a component fails due to chemical attack, it results in costly operational downtime for repairs and replacement.

By using PTFE in critical parts, organizations can dramatically extend the service life of their equipment. This leads to fewer maintenance cycles and a lower total cost of ownership.

Understanding the Boundaries of PTFE's Resistance

Known Chemical Exceptions

While its resistance is exceptional, PTFE is not entirely invincible.

A very small number of substances can affect it. These include highly reactive agents like molten alkali metals, chlorine trifluoride, and elementary fluorine under specific conditions.

For the vast majority of industrial applications, however, these exceptions are not a factor.

Susceptibility to Radiation

The most significant limitation of PTFE is its relatively poor resistance to high-energy radiation.

Sufficient exposure to gamma rays or electron beams can cause the breakdown of PTFE's molecular structure, leading to a loss of its physical properties.

This is a critical consideration in nuclear or high-radiation environments.

Making the Right Choice for Your Application

Choosing a material is always about matching its properties to the operational environment.

- If your primary focus is reliability in chemical processing: PTFE is an unparalleled choice for components that will have direct contact with a wide range of corrosive fluids.

- If your application involves high-energy radiation: You must carefully evaluate the radiation levels, as PTFE may degrade and an alternative material would be required.

- If you are handling extreme reactive agents like molten alkali metals: PTFE is not suitable, and you must select a material specifically designed for those conditions.

Ultimately, leveraging PTFE's chemical resistance is about deploying it where its near-total inertness provides a decisive advantage in safety and long-term performance.

Summary Table:

| Key Benefit | Description |

|---|---|

| Broad Chemical Resistance | Resists nearly all industrial chemicals, including strong acids, bases, and solvents. |

| Component Integrity | Maintains physical form and function, preventing leaks and equipment failure. |

| Reduced Downtime | Extends equipment service life, leading to fewer maintenance cycles. |

| Cost-Effectiveness | Lowers total cost of ownership by minimizing replacements. |

| Known Limitations | Not suitable for high-energy radiation or extreme reactive agents (e.g., molten alkali metals). |

Maximize Your Operational Safety and Efficiency with KINTEK's PTFE Components

PTFE's legendary chemical resistance is the key to reliability in harsh environments. At KINTEK, we specialize in manufacturing precision PTFE components—including custom seals, liners, and labware—for the semiconductor, medical, laboratory, and industrial sectors. Our expertise ensures your equipment withstands corrosive chemicals, reducing downtime and protecting your bottom line.

Ready to enhance your application's performance and longevity? Contact KINTEK today to discuss your custom fabrication needs, from prototypes to high-volume orders.

Visual Guide

Related Products

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

- Custom PTFE Square Trays for Industrial and Laboratory Use

- Custom PTFE Bottles for Diverse Industrial Applications

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

People Also Ask

- Why is chemical compatibility important when choosing a PTFE-coated septum? Avoid Sample Contamination and Data Loss

- Why are PTFE vials considered environmentally friendly? Reduce Lab Waste with Durable Reusables

- What are some exceptional properties of PTFE? Unlock Unmatched Performance in Extreme Environments

- In which industries is PTFE commonly used? Key Applications for Chemical & Thermal Resistance

- What makes the PTFE bottle durable? Unmatched Chemical & Thermal Stability for Demanding Applications