At their core, PTFE lined butterfly valves are a preferred choice for industrial applications because they provide an economical way to achieve superior chemical resistance and reliable sealing across a wide temperature range. By isolating the valve body and stem from corrosive media, the PTFE liner allows for the use of less expensive body materials without compromising safety or performance.

The true value of a PTFE lined butterfly valve isn't just the valve itself, but the engineering principle it employs: using a highly inert, non-reactive liner to protect robust, cost-effective structural components from chemically aggressive environments. This delivers high performance without the high cost of exotic alloys.

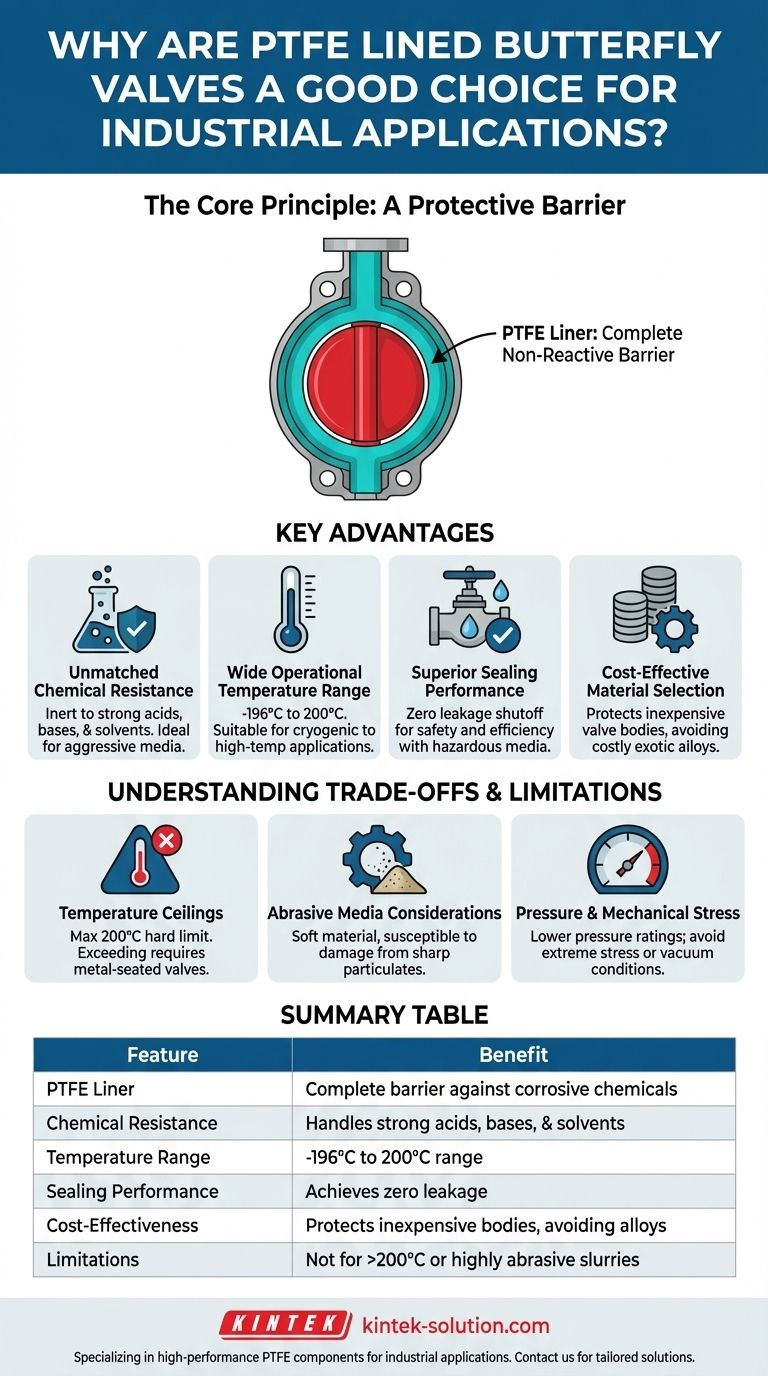

The Core Principle: A Protective Barrier

The effectiveness of a PTFE lined valve comes from its intelligent and simple design. It separates the function of structural integrity from the function of chemical compatibility.

How the PTFE Liner Works

The entire wetted surface of the valve—the interior of the body and the exterior of the disc—is encapsulated in a thick, molded layer of Polytetrafluoroethylene (PTFE). This liner acts as a complete, non-reactive barrier, ensuring that the process fluid only ever comes into contact with the PTFE.

This design means the valve body, typically made of cast iron or carbon steel, is never exposed to the corrosive media.

Simple and Effective Valve Design

Like other butterfly valves, they operate on a simple quarter-turn (90-degree) principle. An actuator or handle rotates a stem, which turns the disc inside the pipe to either allow or block flow.

This makes them quick to operate and easy to automate, providing efficient control for both isolation (on/off) and regulation (throttling) services.

Key Advantages in Demanding Environments

The combination of this design and PTFE's material properties creates a valve well-suited for the challenges of modern industry.

Unmatched Chemical Resistance

PTFE is one of the most chemically inert polymers known. It is virtually immune to attack from strong acids, bases, solvents, and other corrosive chemicals that would quickly destroy most metals.

This makes it an ideal choice for industries like chemical processing, pharmaceuticals, and petrochemicals, where aggressive media is common.

Wide Operational Temperature Range

PTFE maintains its integrity and performance across an exceptionally broad temperature spectrum, typically rated for service from -196°C to 200°C (-320°F to 392°F).

This versatility allows it to be used in applications ranging from cryogenic processes to moderately high-temperature chemical reactions.

Superior Sealing Performance

The "soft" nature of the PTFE seat allows it to form a tight seal around the disc when the valve is closed. This provides excellent shutoff capabilities, often achieving zero leakage.

This level of sealing is critical for safety in systems handling hazardous or toxic media and for efficiency in preventing product loss.

Cost-Effective Material Selection

Because the liner provides all the necessary chemical protection, the valve body does not need to be made from expensive, corrosion-resistant alloys like stainless steel or Hastelloy.

This significantly reduces the overall cost of the valve, making it a highly economical solution for corrosive service, especially in larger pipe sizes.

Understanding the Trade-offs and Limitations

While highly effective, PTFE lined valves are not a universal solution. Understanding their limitations is key to proper application.

Temperature Ceilings

The 200°C (392°F) upper temperature limit is a hard ceiling. For applications involving higher temperatures, such as high-pressure steam or certain chemical processes, a metal-seated butterfly valve is required.

Abrasive Media Considerations

PTFE is a relatively soft material. While suitable for many slurries, it can be susceptible to damage from highly abrasive media with sharp particulates. In such cases, a more robust lining or a different valve type may be a better long-term solution.

Pressure and Mechanical Stress

Soft-seated valves like these generally have lower pressure ratings compared to their metal-seated counterparts. The mechanical properties of PTFE can also make it unsuitable for extreme mechanical stress or vacuum conditions where liner collapse could be a risk.

Making the Right Choice for Your System

Selecting the correct valve requires matching its capabilities to your specific operational goal.

- If your primary focus is handling aggressive chemicals: PTFE's near-total chemical inertness makes it an industry-standard choice for safe and reliable flow control.

- If your primary focus is cost-efficiency in a corrosive environment: PTFE-lined valves deliver the performance of exotic alloys at a fraction of the cost by protecting an inexpensive valve body.

- If your primary focus is high-temperature service (above 200°C) or highly abrasive slurries: You should evaluate specialized solutions like metal-seated butterfly valves or knife gate valves.

Ultimately, choosing a PTFE lined butterfly valve is an informed engineering decision that balances performance, safety, and cost for a huge range of industrial processes.

Summary Table:

| Feature | Benefit |

|---|---|

| PTFE Liner | Provides a complete, non-reactive barrier against corrosive chemicals. |

| Chemical Resistance | Handles strong acids, bases, and solvents, ideal for chemical processing and pharmaceuticals. |

| Temperature Range | Operates from -196°C to 200°C, suitable for cryogenic to high-temperature processes. |

| Sealing Performance | Achieves zero leakage for safety and efficiency with hazardous media. |

| Cost-Effectiveness | Protects inexpensive valve bodies (e.g., cast iron), avoiding costly exotic alloys. |

| Limitations | Not for temperatures >200°C or highly abrasive slurries; consider metal-seated valves. |

Need a reliable valve solution for your corrosive application? KINTEK specializes in manufacturing high-performance PTFE components, including custom liners and seals for butterfly valves. Our precision engineering ensures durability and chemical resistance for industries like semiconductor, medical, and laboratory. Whether you need prototypes or high-volume orders, we deliver cost-effective, tailored solutions. Contact us today to discuss your requirements and enhance your system's performance!

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

- Customizable PTFE Seals Filter Holders for Versatile Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

People Also Ask

- What is the modulus of elasticity for PTFE according to tensile tests? Understand Its Real-World Performance

- In which industries are machined PTFE parts commonly used? Discover the Essential High-Performance Material

- What types of fluids can PTFE O-Rings repel? The Ultimate Guide to Chemical Resistance

- What types of fasteners can be made from PTFE? A Guide to Chemical-Resistant, Low-Friction Components

- What types of applications are PTFE piston seals suitable for? The Ultimate Guide for Demanding Environments

- Why are fillers added to PTFE compounds? Enhance Wear, Strength, and Performance

- What is another name for PTFE V Ring? It's Also Known as a Teflon V Ring

- Why is cryogenic deburring particularly suitable for Teflon parts? Achieve a Perfect, Damage-Free Finish