In short, cryogenic deburring is uniquely suited for Teflon because it uses extreme cold, not heat, to remove imperfections. This process makes unwanted burrs brittle and easy to snap off while completely avoiding the risk of thermal damage, warping, or chemical alteration that Teflon is highly susceptible to with other methods.

The core principle is simple yet powerful: by leveraging extreme cold, cryogenic deburring removes unwanted material without compromising the dimensional stability or chemical integrity of the finished Teflon part. It is a process of finesse, not destructive force.

The Core Challenge: Finishing a Sensitive Material

To understand why cryogenic deburring is the superior choice, we must first appreciate the specific properties of Teflon (PTFE) and the problems these properties create for traditional finishing methods.

Why Teflon is Difficult to Deburr

Teflon is a soft polymer with a relatively low melting point and high sensitivity to heat. While valued for its chemical inertness and low friction, these same characteristics make it vulnerable during manufacturing.

Standard deburring techniques that rely on heat, friction, or harsh chemicals are often unsuitable. They can easily cause melting, warping, or a loss of the precise dimensions required for high-performance applications.

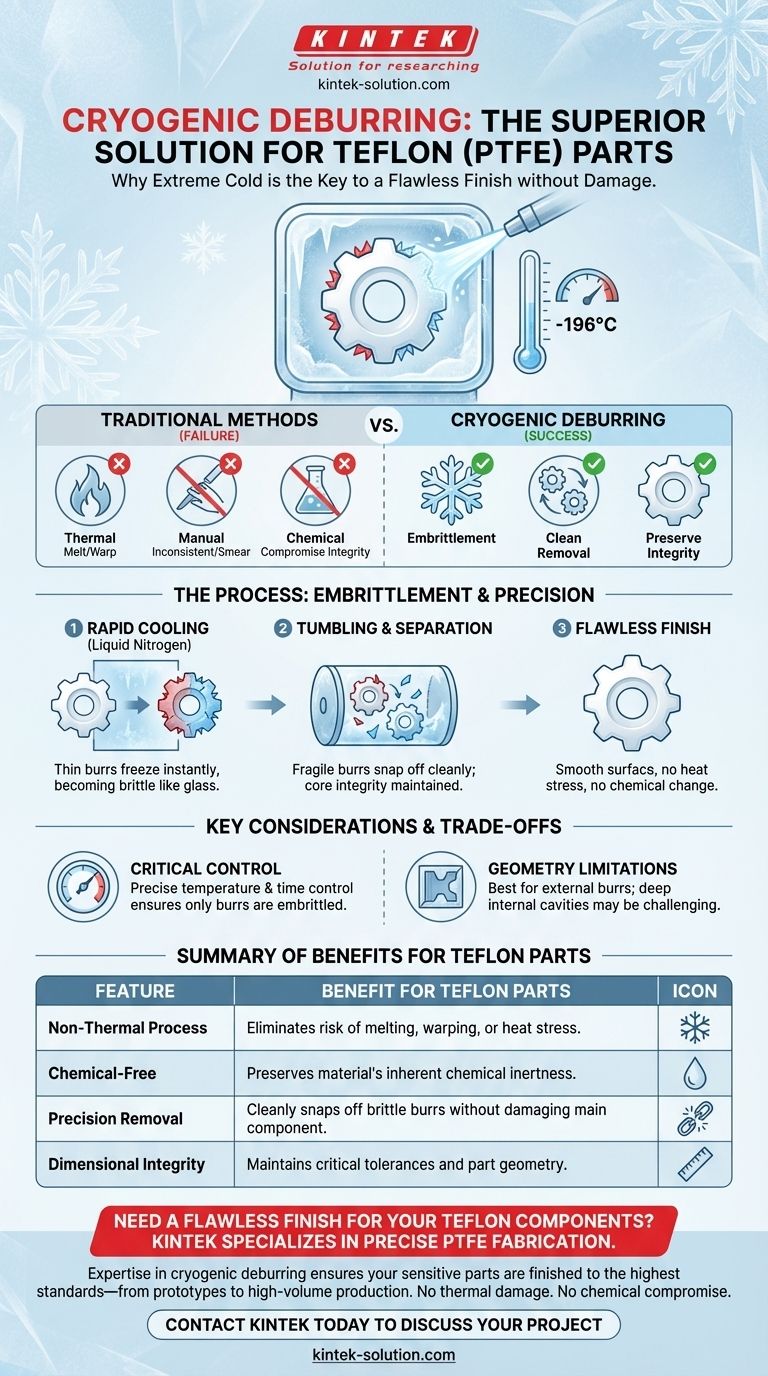

The Failure of Traditional Methods

Thermal deburring, which uses a burst of heat, would simply melt or deform a Teflon component.

Manual or mechanical deburring often leads to inconsistent results. It can smear the soft material rather than cutting it cleanly, potentially creating new surface imperfections.

Chemical deburring is also not an option, as it would compromise the very chemical inertness that makes Teflon a critical material in many industries.

How Cryogenic Deburring Solves the Teflon Problem

Cryogenic deburring turns Teflon's thermal sensitivity from a liability into an asset. The process is elegant and precise, consisting of a few key stages.

The Principle of Embrittlement

Parts are exposed to extremely low temperatures, typically using liquid nitrogen. This rapid cooling has a differential effect.

The thin, unwanted burrs and flashing have a low thermal mass and freeze almost instantly, becoming extremely brittle like glass.

Clean and Precise Removal

The main body of the Teflon part has a much greater thermal mass and is not exposed long enough to become fully brittle. Its core integrity and flexibility are maintained.

While in this embrittled state, the parts are gently tumbled. The frozen burrs are so fragile that they cleanly snap off, leaving a smooth, high-quality surface without damaging the component itself.

Preserving Material Integrity

Because the process uses only cold and a gentle mechanical action, the fundamental properties of the Teflon part remain unchanged. There is no heat-induced stress, no chemical reaction, and no abrasive wear on the primary surfaces.

Key Considerations and Trade-offs

While highly effective, the cryogenic process is not a universal solution. It's an industrial method with specific requirements and limitations.

Process Control is Critical

The success of cryogenic deburring depends entirely on precise control over temperature and exposure time. This ensures only the burrs become brittle, protecting the main component from becoming too fragile.

Not for All Geometries

The process is most effective for removing external burrs or those in easily accessible areas. Deep internal burrs in complex cavities may not be reliably removed, as the tumbling action may not reach them effectively.

Making the Right Choice for Your Goal

Cryogenic deburring is an engineered solution for a specific set of challenges. Its suitability depends entirely on your project's priorities.

- If your primary focus is preserving dimensional accuracy and material purity: Cryogenic deburring is the ideal choice, as it introduces no heat stress or chemical contaminants.

- If your primary focus is achieving high-volume, repeatable results: This automated process delivers a level of consistency and quality that is virtually impossible to achieve with manual finishing.

- If you are dealing with delicate parts with fine flash: The process excels at cleanly removing small, thin imperfections without impacting the integrity of the component's structure.

Ultimately, cryogenic deburring offers a precise and non-destructive method to achieve a perfect finish on a challenging material like Teflon.

Summary Table:

| Feature | Benefit for Teflon Parts |

|---|---|

| Non-Thermal Process | Eliminates risk of melting, warping, or heat stress. |

| Chemical-Free | Preserves the material's inherent chemical inertness. |

| Precision Removal | Cleanly snaps off brittle burrs without damaging the main component. |

| Dimensional Integrity | Maintains critical tolerances and part geometry. |

Need a flawless finish for your Teflon components?

KINTEK specializes in the precise fabrication of PTFE components like seals, liners, and labware for the semiconductor, medical, and laboratory industries. Our expertise in cryogenic deburring ensures your sensitive Teflon parts are finished to the highest standards, with no risk of thermal damage or chemical compromise—from prototypes to high-volume production.

Contact KINTEK today to discuss your project and get a quote!

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Customizable PTFE Crucibles for Laboratory and Industrial Applications

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

People Also Ask

- How does PTFE contribute to low friction and wear resistance? Achieve Superior Performance with Advanced Materials

- What industries use PTFE machined parts and for what applications? Critical Components for Demanding Environments

- What are the main advantages of using PTFE parts in industrial applications? Unlock Unmatched Chemical Resistance and Reliability

- Why is CNC machining preferred for Teflon parts over other methods? Unlock Precision & Complex Designs

- What are the best practices for achieving tight tolerances in Teflon (PTFE) machining? Master Precision for Demanding Applications