In short, PTFE piston seals are engineered for demanding dynamic applications, most notably reciprocating motion, but also for slow rotary and slow oscillating movements. They excel in environments where standard elastomeric seals would fail due to extreme temperatures, high pressures, aggressive chemicals, or the need for very low friction.

The suitability of a PTFE piston seal is not defined by an industry, but by the operational challenge. These seals are the solution for dynamic applications in harsh environments where performance characteristics like temperature resistance, low friction, and chemical inertness are non-negotiable.

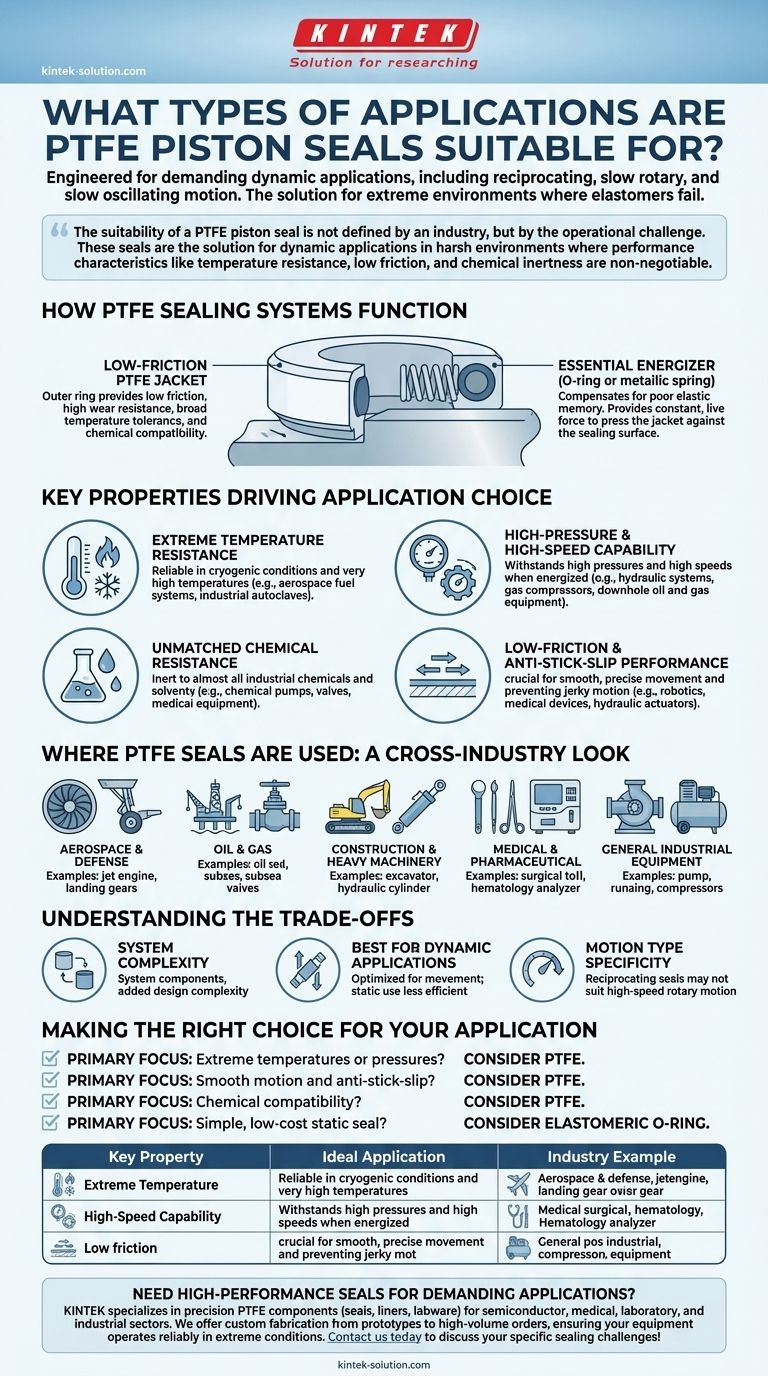

How PTFE Sealing Systems Function

PTFE (Polytetrafluoroethylene) is a remarkable material, but it is not inherently elastic. Understanding its role as part of a system is critical to its proper application.

The Low-Friction PTFE Jacket

The outer ring, or "jacket," of the seal is made from a PTFE compound. This is the component that contacts the moving surface.

This jacket provides the core benefits of the seal: extremely low friction, high wear resistance, broad temperature tolerance, and near-universal chemical compatibility.

The Essential Energizer

Because PTFE has poor "elastic memory," it will not spring back into shape after being compressed. It cannot maintain a sealing force on its own.

Therefore, a PTFE piston seal must be used with an energizer. This is typically a standard O-ring or a metallic spring that sits behind the PTFE jacket, providing the constant, live force needed to press the jacket against the sealing surface.

Key Properties Driving Application Choice

Engineers specify PTFE seals when facing one or more of the following operational demands. The specific industry is a consequence of these demands.

Extreme Temperature Resistance

PTFE seals function reliably in both cryogenic conditions and at very high temperatures where traditional rubber seals would become brittle or degrade. This makes them suitable for aerospace fuel systems and industrial autoclaves alike.

High-Pressure and High-Speed Capability

When energized, typically with a spring, these seals can withstand extremely high system pressures. They are a staple in high-pressure hydraulic systems, gas compressors, and downhole oil and gas equipment. Specially designed variants are also used for high-speed rotary applications.

Unmatched Chemical Resistance

PTFE is inert to almost all industrial chemicals, solvents, and corrosive substances. This makes it the default choice for chemical processing pumps, valves, and medical equipment that undergoes harsh sterilization.

Low-Friction and Anti-Stick-Slip Performance

The coefficient of friction for PTFE is one of the lowest of any solid material. This property is crucial in applications requiring smooth, precise movement, such as in robotics, medical devices, and hydraulic actuators, as it prevents jerky "stick-slip" motion.

Where PTFE Seals Are Used: A Cross-Industry Look

The properties above make PTFE seals indispensable across many advanced sectors.

Aerospace and Defense

Applications are widespread, including landing gear actuators, flight control hydraulic systems, turbine engines, fuel systems, and cryogenic valves where temperature extremes and reliability are paramount.

Oil and Gas

In this sector, seals face high-pressure, high-temperature (HPHT) conditions. They are used in downhole tools, subsea equipment, valves, and pumps handling aggressive media.

Construction and Heavy Machinery

PTFE seals provide the durability and wear resistance needed for the hydraulic cylinders in excavators, loaders, and other heavy equipment.

Medical and Pharmaceutical

Due to its inertness and ability to be sterilized, PTFE is used in surgical tools, fluid handling systems, and analytical equipment like hematology analyzers.

General Industrial Equipment

You will find PTFE seals providing reliable service in a vast range of machinery, including industrial pumps, compressors, mixers, gearboxes, and motors where service life and performance are critical.

Understanding the Trade-offs

While powerful, PTFE seals are not a universal solution. Their design brings specific considerations.

System Complexity

A PTFE seal is a two-component system (jacket and energizer). This adds a degree of complexity to design and assembly compared to a single elastomeric O-ring.

Best for Dynamic Applications

These seals are specifically designed for movement. For purely static applications where there is no movement, a simpler and more cost-effective O-ring is often the superior choice.

Motion Type Specificity

While versatile, a seal designed for reciprocating motion (piston) is not always ideal for high-speed rotary motion. Rotary applications often require a different seal profile, known as a rotary shaft seal or lip seal, which may also use PTFE.

Making the Right Choice for Your Application

Use these guidelines to determine if a PTFE piston seal aligns with your project's primary goal.

- If your primary focus is extreme temperatures or pressures: A PTFE seal is one of the best available options and should be strongly considered.

- If your primary focus is preventing stick-slip and ensuring smooth motion: The low-friction nature of PTFE makes it a leading candidate.

- If your primary focus is chemical compatibility: PTFE's inertness makes it a safe and reliable choice for sealing against aggressive media.

- If your primary focus is a simple, low-cost seal for a static application: A standard elastomeric O-ring is likely a more appropriate and economical solution.

Ultimately, selecting a PTFE piston seal means choosing a high-performance solution engineered to succeed where conventional seals cannot.

Summary Table:

| Key Property | Ideal Application | Industry Example |

|---|---|---|

| Extreme Temperature Resistance | Cryogenic to high-heat systems | Aerospace fuel systems, industrial autoclaves |

| High-Pressure & High-Speed Capability | Hydraulic systems, compressors | Oil & gas downhole tools, heavy machinery |

| Unmatched Chemical Resistance | Pumps, valves, sterilization equipment | Chemical processing, medical devices |

| Low-Friction & Anti-Stick-Slip Performance | Precision motion systems | Robotics, hydraulic actuators, analytical equipment |

Need high-performance seals for demanding applications? KINTEK specializes in precision PTFE components (seals, liners, labware) for semiconductor, medical, laboratory, and industrial sectors. We offer custom fabrication from prototypes to high-volume orders, ensuring your equipment operates reliably in extreme conditions. Contact us today to discuss your specific sealing challenges!

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Teflon Balls for Advanced Industrial Applications

People Also Ask

- What challenges arise when machining PTFE (Teflon)? Overcome Softness, Heat, and Instability

- What industrial benefits do PTFE-machined parts offer? Achieve Peak Performance in Demanding Applications

- What are the unique properties of PTFE? The 3 Pillars Driving Demand for High-Performance Parts

- What finishing techniques are effective for machined Teflon parts? Achieve Functional Performance and Dimensional Stability

- What are the main applications of PTFE type Teflon? Unlock Its Versatility for Your Industry