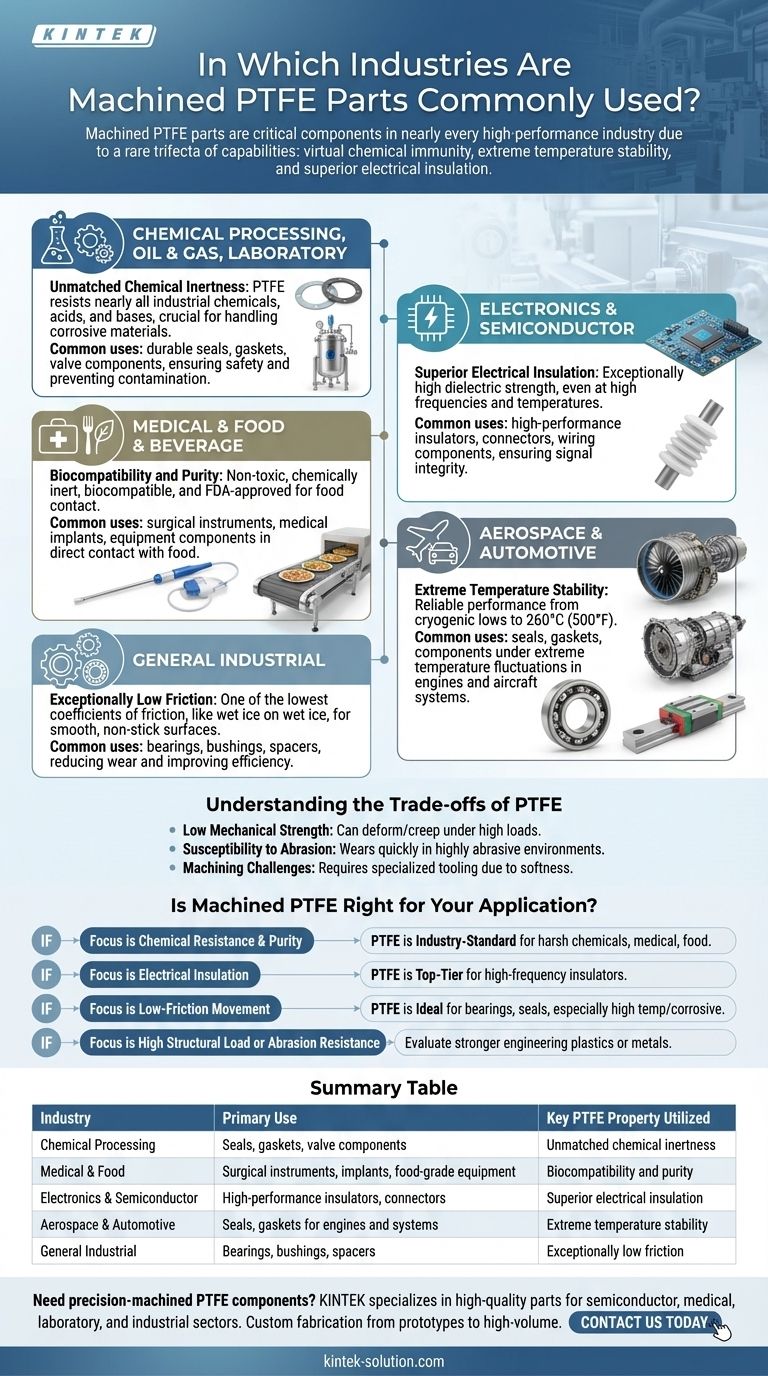

In short, machined PTFE parts are critical components in nearly every high-performance industry, including aerospace, medical, chemical processing, electronics, and food manufacturing. Its unique combination of properties makes it a go-to material for applications where extreme chemical resistance, temperature stability, and electrical insulation are non-negotiable.

The widespread use of machined PTFE is not due to a single feature, but its rare trifecta of capabilities: it is virtually immune to chemical attack, stable across a vast temperature range, and one of the best electrical insulators known. This makes it an essential problem-solver in environments where other materials would quickly fail.

Why PTFE is a Material of Choice in Demanding Sectors

The value of Polytetrafluoroethylene (PTFE) comes from its distinct molecular structure, which gives it a set of high-performance characteristics. Different industries leverage specific properties to solve their most difficult engineering challenges.

Unmatched Chemical Inertness

PTFE is resistant to nearly all industrial chemicals, acids, and bases. This makes it indispensable for handling corrosive materials.

This property is critical in the chemical processing, oil and gas, and laboratory equipment industries. It is commonly machined into durable seals, gaskets, and valve components that ensure safety and prevent contamination.

Superior Electrical Insulation

PTFE has an exceptionally high dielectric strength, meaning it is an excellent electrical insulator. It maintains this property even at high frequencies and temperatures.

This makes it a primary material in the electronics and semiconductor industries for manufacturing high-performance insulators, connectors, and wiring components where signal integrity is paramount.

Biocompatibility and Purity

PTFE is non-toxic, chemically inert, and biocompatible, meaning it does not react with bodily fluids. It is also approved by the FDA for food contact applications.

These characteristics are vital for the medical and food and beverage industries. It's used for surgical instruments, medical implants, and equipment components that come in direct contact with food products.

Extreme Temperature Stability

Machined PTFE parts can perform reliably across a wide temperature range, from cryogenic lows to highs of around 260°C (500°F).

This thermal stability is essential for the aerospace and automotive sectors. It's used for seals, gaskets, and components that must function perfectly under the extreme temperature fluctuations found in engines and aircraft systems.

Exceptionally Low Friction

PTFE has one of the lowest coefficients of friction of any solid material, often compared to wet ice on wet ice. This makes it ideal for applications requiring smooth, non-stick surfaces.

This property is leveraged across many sectors for machinery components like bearings, bushings, and spacers, reducing wear and improving the efficiency of moving parts.

Understanding the Trade-offs of PTFE

While its strengths are significant, PTFE is not the solution for every problem. Understanding its limitations is key to using it effectively.

Low Mechanical Strength

PTFE is a relatively soft material. It is not suitable for high-load structural applications, as it can deform or "creep" under constant pressure.

Susceptibility to Abrasion

The softness and low friction that make PTFE ideal for sliding applications also mean it can wear down quickly in highly abrasive environments.

Machining Challenges

Although it can be machined to tight tolerances, its softness requires specialized tooling and expertise to prevent deformation and achieve a clean finish without burrs.

Is Machined PTFE Right for Your Application?

Choosing the right material requires matching its properties to your primary goal. Use these guidelines to determine if PTFE is the optimal choice for your project.

- If your primary focus is chemical resistance and purity: PTFE is an industry-standard choice for any application involving harsh chemicals, medical devices, or food-grade equipment.

- If your primary focus is electrical insulation: PTFE's dielectric properties make it a top-tier material for high-frequency insulators and critical electronic components.

- If your primary focus is low-friction movement: PTFE is ideal for bearings, seals, and sliding components, especially in high-temperature or corrosive environments.

- If your primary focus is high structural load or abrasion resistance: You should evaluate stronger engineering plastics or metals, as PTFE may deform or wear prematurely in these conditions.

By understanding both its unique strengths and its practical limitations, you can confidently specify machined PTFE for applications where performance and reliability are paramount.

Summary Table:

| Industry | Primary Use of PTFE Parts | Key PTFE Property Utilized |

|---|---|---|

| Chemical Processing | Seals, gaskets, valve components | Unmatched chemical inertness |

| Medical & Food | Surgical instruments, implants, food-grade equipment | Biocompatibility and purity |

| Electronics & Semiconductor | High-performance insulators, connectors | Superior electrical insulation |

| Aerospace & Automotive | Seals, gaskets for engines and systems | Extreme temperature stability |

| General Industrial | Bearings, bushings, spacers | Exceptionally low friction |

Need precision-machined PTFE components for your industry? KINTEK specializes in manufacturing high-quality PTFE parts—including seals, liners, and labware—for the semiconductor, medical, laboratory, and industrial sectors. We offer custom fabrication from prototypes to high-volume orders, ensuring precision and reliability. Contact us today to discuss your specific requirements and get a quote!

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Customizable PTFE Rods for Advanced Industrial Applications

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

People Also Ask

- What are the future considerations for machining Teflon? Mastering Material Challenges with Smart Tech

- What tips can improve Teflon machining results? Master Sharp Tools, Heat Control, and Rigid Support

- What are the key considerations when machining Teflon? Master Precision Machining for Soft Polymers

- Why is CNC machining preferred for Teflon parts over other methods? Unlock Precision & Complex Designs

- What are the main advantages of using PTFE parts in industrial applications? Unlock Unmatched Chemical Resistance and Reliability