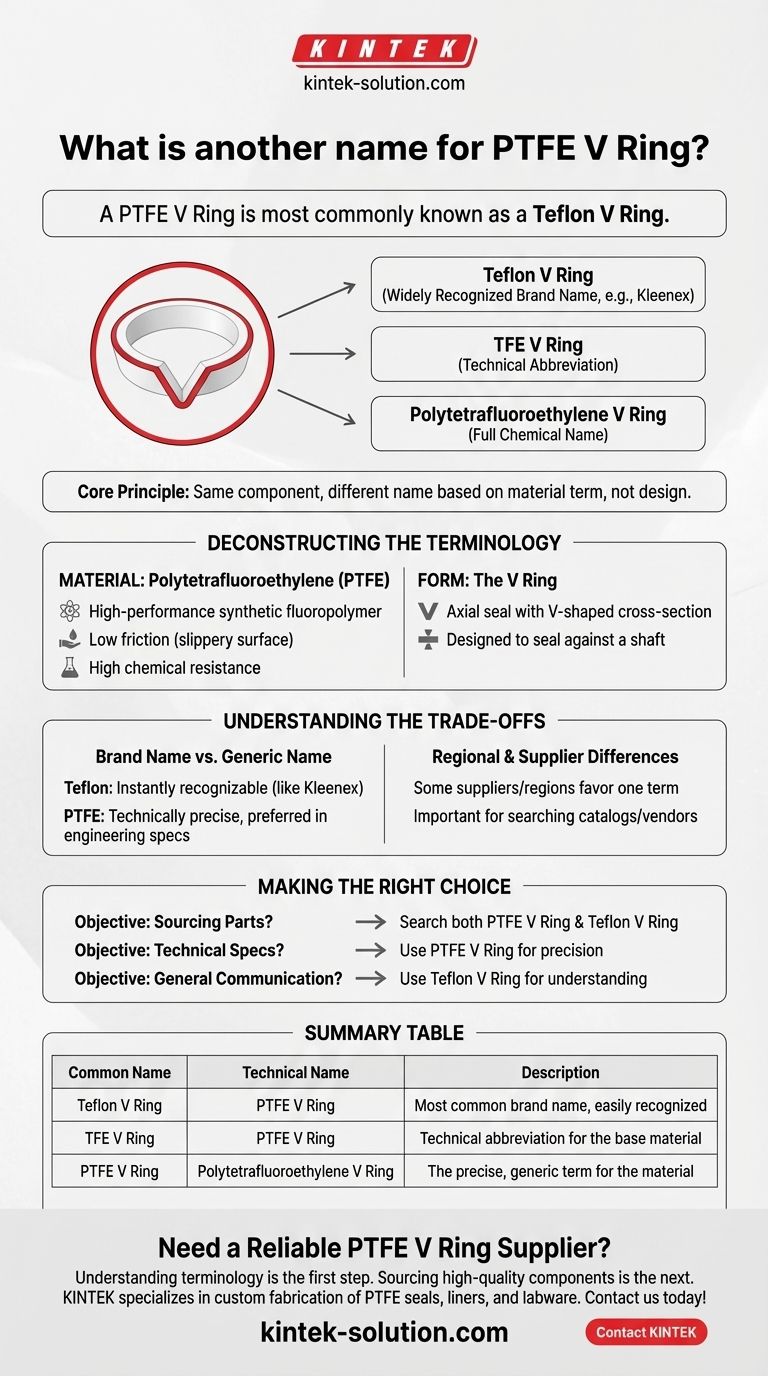

A PTFE V Ring is most commonly known as a Teflon V Ring. This alternative name arises because "Teflon" is a widely recognized brand name for the material Polytetrafluoroethylene (PTFE). Therefore, other valid names include "TFE V Ring" and the full chemical name, "Polytetrafluoroethylene V Ring."

The core principle is that the component's name changes based on the term used for its material, not a change in its design or function. Whether it's called a PTFE V Ring or a Teflon V Ring, you are referring to the exact same part: a V-shaped seal made from Polytetrafluoroethylene.

Deconstructing the Terminology

To fully understand the naming conventions, it's best to break the term "PTFE V Ring" into its two constituent parts: the material and the form.

The Material: Polytetrafluoroethylene (PTFE)

Polytetrafluoroethylene, abbreviated as PTFE, is a high-performance synthetic fluoropolymer. It is prized in engineering for its exceptional properties, including very low friction (a slippery surface) and high chemical resistance.

Common Synonyms for PTFE

This material is known by several names, which is the root of the confusion.

- Teflon: This is the most famous trade name for PTFE, originally registered by DuPont and now owned by Chemours. It has become so common that it's often used generically.

- TFE: This is a common technical abbreviation for the monomer used to create the polymer (Tetrafluoroethylene), and is often used as shorthand for PTFE itself in technical contexts.

- Fluon: This is another trade name for PTFE, manufactured by the AGC Group.

The Form: The V Ring

The "V Ring" portion of the name describes the component's geometry and function. It is a specific type of axial seal with a V-shaped cross-section designed to seal against a shaft. This part of the name remains consistent regardless of the material term used.

Understanding the Trade-offs in Terminology

Using different names for the same component can create both clarity and confusion. Understanding the context helps you navigate the landscape effectively.

Brand Name vs. Generic Name

Using Teflon is similar to using "Kleenex" for a tissue. It is instantly recognizable to a broad audience but is technically a brand name, not the generic material name.

Using PTFE is more technically precise and is the preferred term in engineering specifications, academic papers, and technical data sheets. It refers to the material itself, without endorsing a specific manufacturer.

Regional and Supplier Differences

Some suppliers or regions may favor one term over another. Being familiar with both "PTFE V Ring" and "Teflon V Ring" is crucial when searching catalogs or communicating with different vendors to ensure you find the component you need.

Making the Right Choice for Your Goal

Ultimately, the name you use depends on your objective. The key is knowing they all point to the same component with the same core properties.

- If your primary focus is sourcing parts: Search using both "PTFE V Ring" and "Teflon V Ring" to maximize your results and compare a wider range of suppliers.

- If your primary focus is writing technical specifications: Use "PTFE V Ring" for precision and to avoid specifying a single brand, which can limit sourcing options.

- If your primary focus is general communication: Use "Teflon V Ring," as it is the most widely understood term among non-specialists.

Understanding that these terms are interchangeable empowers you to communicate clearly and source components with confidence.

Summary Table:

| Common Name | Technical Name | Description |

|---|---|---|

| Teflon V Ring | PTFE V Ring | Most common brand name, easily recognized. |

| TFE V Ring | PTFE V Ring | Technical abbreviation for the base material. |

| PTFE V Ring | Polytetrafluoroethylene V Ring | The precise, generic term for the material. |

Need a Reliable PTFE V Ring Supplier?

Understanding the terminology is the first step. Sourcing high-quality, precision-manufactured PTFE (Teflon) components is the next. KINTEK specializes in custom fabrication of PTFE seals, liners, and labware for the semiconductor, medical, laboratory, and industrial sectors. Whether you need prototypes or high-volume orders, we deliver components that meet exact specifications.

Contact KINTEK today to discuss your PTFE component requirements and get a quote!

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Teflon Balls for Advanced Industrial Applications

People Also Ask

- How does the temperature resistance of PTFE O-rings compare to other materials? Superior Performance from -250°C to +260°C

- What is PTFE and why is it used in Teflon bearings? Achieve Maintenance-Free Performance in Harsh Environments

- What are some common applications of Teflon? From Cookware to Aerospace Components

- What is the temperature range that PTFE gaskets can withstand? A Guide from -200°C to +260°C

- What are the key advantages of using PTFE envelope gaskets? Superior Sealing for Aggressive Chemical & High-Pressure Applications

- What temperature limitations should be considered when using PTFE lined butterfly valves? Ensure Safe & Reliable Operation

- At what low temperature does PTFE Teflon O-ring still maintain compressive plasticity? Achieve Reliable Sealing to Near Absolute Zero

- How does graphite-filled PTFE improve sealing performance? Enhance Wear Resistance & Self-Lubrication