Polytetrafluoroethylene, or PTFE, is a high-performance synthetic fluoropolymer. It is the material used in Teflon bearings because of its unique combination of an extremely low coefficient of friction, high-temperature stability, and exceptional chemical inertness. Essentially, it creates a durable, self-lubricating surface that can withstand harsh operating conditions.

The core value of PTFE in bearings isn't just one property, but the unique combination of a self-lubricating surface with extreme resistance to heat and chemical attack. This makes it an ideal material for applications where traditional lubrication is impractical or would fail.

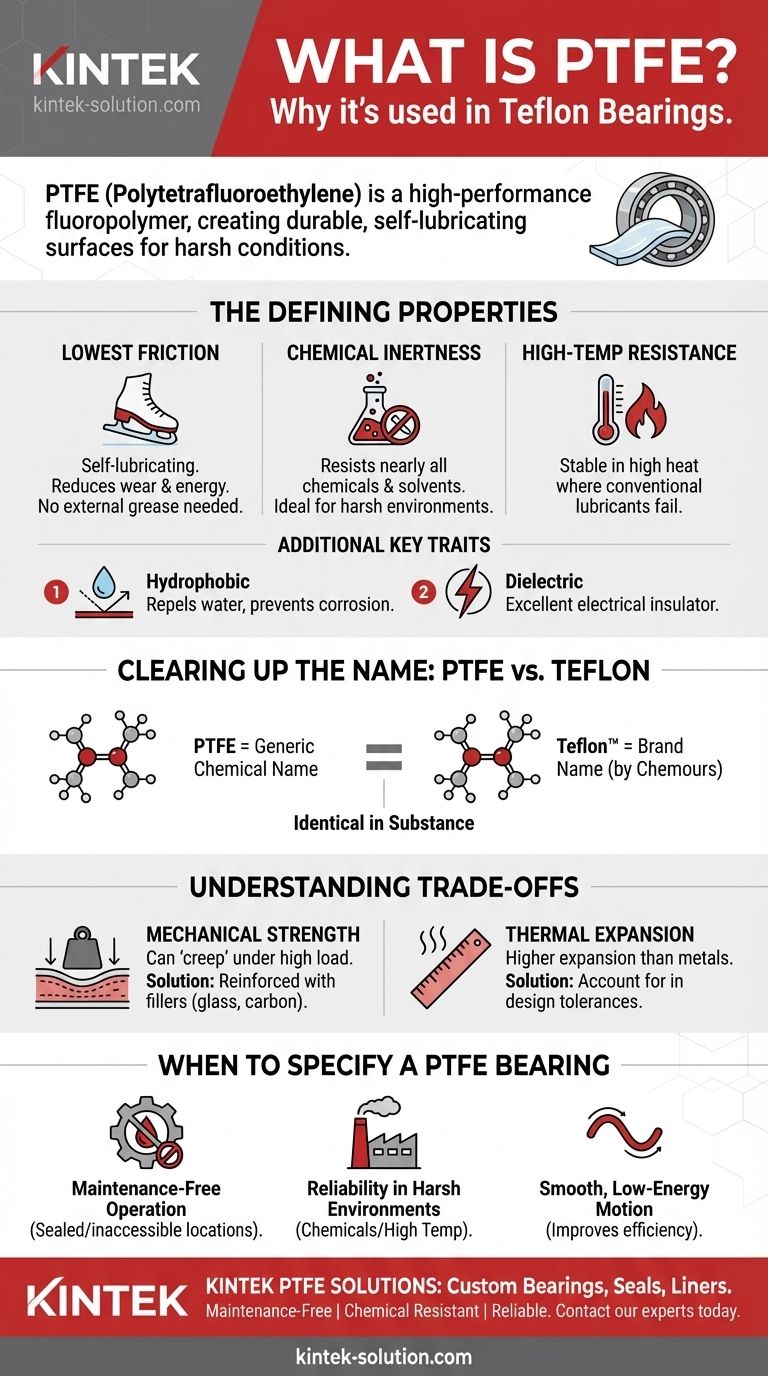

The Defining Properties of PTFE

To understand why PTFE is such a critical material in engineering, we must examine its fundamental characteristics. Each property solves a specific set of challenges faced in mechanical applications.

The Lowest Friction of Any Solid

PTFE possesses one of the lowest coefficients of friction of any known solid material. This means surfaces can slide against each other with minimal resistance.

For bearings, this translates directly to a self-lubricating capability. It reduces wear, minimizes the energy required to operate machinery, and eliminates the need for external lubricants like grease or oil.

Extreme Chemical Inertness

PTFE is non-reactive to nearly all chemicals and solvents. This inertness is a direct result of the strong carbon-fluorine bonds in its molecular structure.

This makes PTFE-lined bearings invaluable in chemical processing, industrial manufacturing, and oil and gas sectors, where they may be exposed to corrosive substances that would destroy traditional metal bearings.

High-Temperature Resistance

PTFE maintains its key properties across a wide range of temperatures. It can operate continuously in high-heat environments without melting or degrading.

This thermal stability allows PTFE bearings to perform reliably in engines, industrial bakeware, and other machinery where high temperatures would cause conventional lubricants to break down or evaporate.

Additional Key Traits

Beyond the primary three, PTFE is also hydrophobic, meaning it repels water, which prevents corrosion and ensures consistent performance in moist environments.

It also has excellent dielectric properties, making it a superb electrical insulator. This is critical in applications where a bearing must prevent the flow of electrical current.

Clearing Up the Name: PTFE vs. Teflon

The two names often cause confusion, but the distinction is simple.

A Matter of Branding

PTFE is the generic, chemical name for the Polytetrafluoroethylene polymer.

Teflon™ is the registered trademark or brand name for PTFE-based products manufactured and sold by the company Chemours.

Identical in Substance

There is no difference in the chemical composition or physical properties between the base material of PTFE and Teflon. The relationship is identical to that of facial tissue and the brand name Kleenex.

Understanding the Trade-offs

No material is perfect for every situation. While its properties are exceptional, it's important to understand the limitations of PTFE to use it effectively.

Mechanical Strength

Pure PTFE is a relatively soft material. Under very high mechanical loads, it can be susceptible to "creep," a slow deformation over time.

For this reason, PTFE in bearings is often used as a liner bonded to a stronger metal shell or is reinforced with fillers like glass, carbon, or bronze to improve its strength and wear resistance.

Thermal Expansion

PTFE has a higher coefficient of thermal expansion than most metals. This means it expands and contracts more significantly with temperature changes.

Engineers must account for this behavior when designing components with tight tolerances to ensure proper fit and function across the entire operating temperature range.

When to Specify a PTFE Bearing

Your choice of bearing material should always be driven by the specific demands of your application.

- If your primary focus is maintenance-free operation: PTFE's self-lubricating nature eliminates the need for external grease or oil, making it ideal for sealed or inaccessible locations.

- If your primary focus is reliability in harsh environments: Its unparalleled resistance to chemicals and high temperatures ensures performance where other materials would quickly fail.

- If your primary focus is smooth, low-energy motion: The extremely low coefficient of friction minimizes startup torque and running resistance, improving efficiency.

Ultimately, PTFE's unique combination of properties makes it a definitive problem-solver for demanding engineering challenges.

Summary Table:

| Property | Benefit for Bearings |

|---|---|

| Lowest Coefficient of Friction | Self-lubricating, reduces wear and energy use |

| Extreme Chemical Inertness | Resists corrosive substances, ideal for harsh environments |

| High-Temperature Resistance | Performs reliably where conventional lubricants fail |

| Hydrophobic & Excellent Dielectric | Repels water, prevents corrosion, and acts as an electrical insulator |

Need a reliable bearing solution for a demanding application?

KINTEK specializes in the precision manufacturing of high-performance PTFE components, including custom bearings, seals, and liners. Our expertise ensures your components deliver maintenance-free operation, extreme chemical resistance, and reliable performance in the most challenging environments—from semiconductor and medical equipment to industrial machinery.

We offer custom fabrication from prototypes to high-volume orders, tailored to your specific requirements. Let's discuss how our PTFE solutions can solve your unique engineering challenge.

Contact our experts today for a consultation.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Square Trays for Industrial and Laboratory Use

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Custom PTFE Volumetric Flasks for Advanced Scientific and Industrial Use

People Also Ask

- What industrial benefits do PTFE-machined parts offer? Achieve Peak Performance in Demanding Applications

- What factors should be considered when choosing between Nylon and PTFE? Select the Right Material for Your Application

- What fabrication services are available for PTFE? Shearing, Stamping, Laser Cutting, Molding & Machining

- What design considerations are important for custom PTFE parts? Design for Performance & Reliability

- What challenges arise when machining PTFE (Teflon)? Overcome Softness, Heat, and Instability