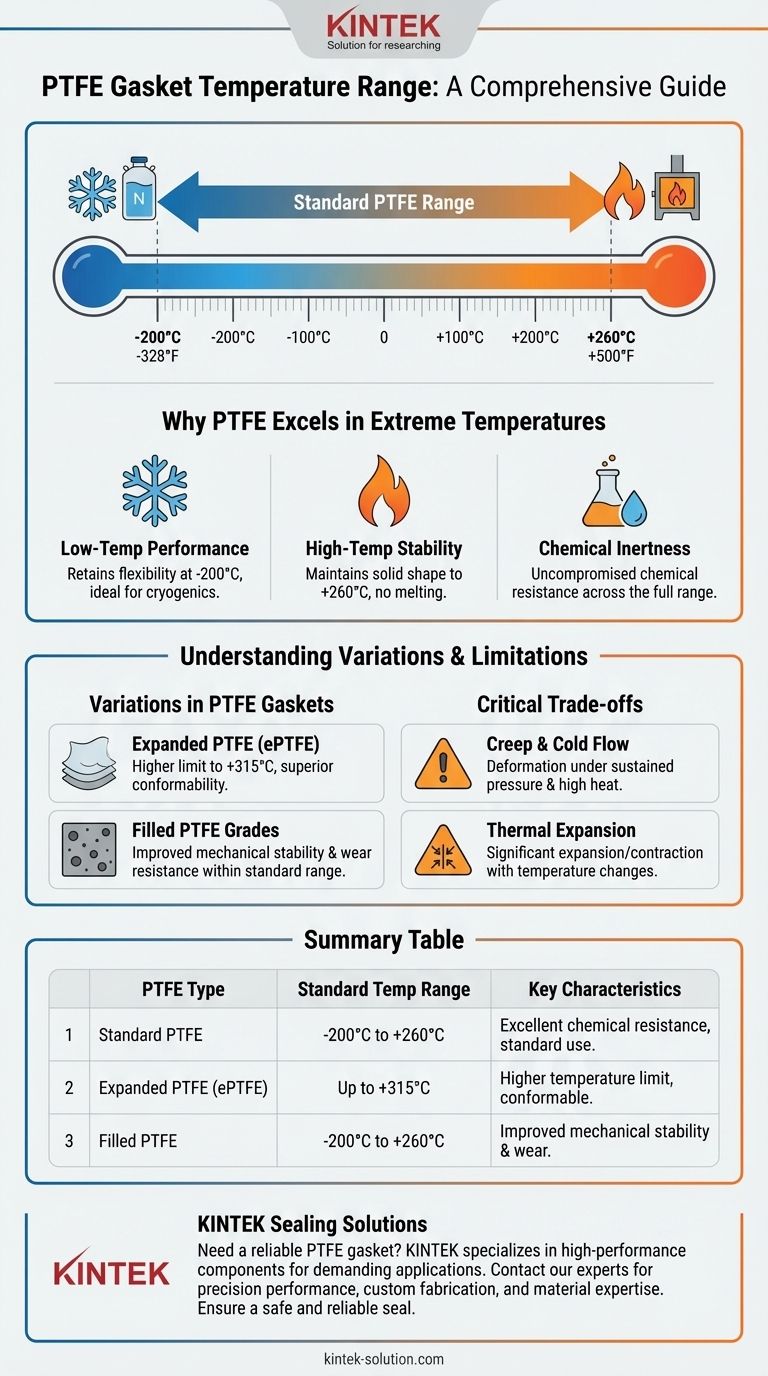

For most industrial applications, a standard PTFE gasket provides a reliable service temperature range from -200°C to +260°C (-328°F to +500°F). This exceptionally wide range makes it one of the few materials suitable for both cryogenic and high-heat sealing challenges. It maintains its integrity and chemical resistance across this entire spectrum.

While PTFE's wide temperature range is impressive, its true value comes from its consistent performance and chemical inertness within that range. However, you must consider how temperature extremes affect its mechanical properties and recognize that specialized forms, like expanded PTFE, offer different capabilities.

Why PTFE Excels in Extreme Temperatures

Polytetrafluoroethylene (PTFE) is not just resistant to temperature; its molecular structure gives it unique stability that other polymers lack. This makes it a default choice for demanding engineering environments.

Low-Temperature Performance (Cryogenics)

Unlike many materials that become extremely brittle and fracture at low temperatures, PTFE retains a useful degree of flexibility and toughness even at -200°C.

This property makes it an essential sealing material for applications involving liquefied gases like nitrogen and oxygen.

High-Temperature Stability

At its upper limit of 260°C, PTFE does not melt. It maintains its solid shape and chemical structure, ensuring a stable and effective seal.

This allows it to be used continuously in high-heat processes found in chemical manufacturing, food processing, and metallurgy without rapid degradation.

Chemical Inertness Across the Range

A critical factor is that PTFE's near-universal chemical resistance is not compromised by temperature.

It remains inert to almost all industrial chemicals, acids, and bases, whether at cryogenic temperatures or at its upper heat limit. This is a rare and highly valuable trait for a sealing material.

Understanding Variations in PTFE Gaskets

Not all PTFE gaskets are created equal. The manufacturing process and composition can alter its performance characteristics, including its temperature limits.

Standard PTFE vs. Expanded PTFE (ePTFE)

Standard, or virgin, PTFE is the baseline material with the widely cited +260°C limit.

Expanded PTFE (ePTFE) is a form of the material that has been modified to create a softer, more conformable structure. This not only helps it seal rough or uneven surfaces but can also push the upper service temperature slightly higher, often to 315°C.

Filled PTFE Grades

PTFE can be blended with filler materials like glass, carbon, or graphite. While these fillers are primarily added to improve mechanical properties like wear resistance and reduce creep, they can also influence thermal performance.

The temperature range for filled PTFE generally remains within the same window as standard PTFE, but its stability and strength at those high temperatures are often improved.

Critical Trade-offs and Limitations

To use PTFE effectively, you must be aware of its inherent limitations, especially when temperature and pressure are combined.

Creep and Cold Flow

PTFE's most well-known weakness is its tendency to creep, or "cold flow," under sustained pressure. This effect is significantly worsened at higher temperatures.

In a bolted flange connection, a gasket under high compressive load at an elevated temperature can slowly deform and thin out, leading to a loss of bolt torque and a potential leak. Proper joint design and torque procedures are critical to mitigate this.

Thermal Expansion

PTFE has a very high coefficient of thermal expansion compared to metals. This means it expands and contracts significantly with temperature changes.

In applications with wide temperature swings, this differential expansion between the PTFE gasket and metal flanges must be accounted for to maintain a consistent sealing pressure.

Performance Near Temperature Limits

While PTFE functions at its temperature limits, its mechanical strength is reduced at the upper end of its range.

The material becomes softer at high temperatures, making it more susceptible to creep and extrusion. The gasket's pressure rating is always dependent on its operating temperature.

Making the Right Choice for Your Application

Selecting the correct PTFE variant requires balancing temperature requirements with mechanical and application demands.

- If your primary focus is cryogenic sealing: Standard PTFE is an excellent choice due to its ability to remain functional and non-brittle at temperatures down to -200°C.

- If your primary focus is high-temperature chemical resistance: Standard PTFE is highly reliable for containing aggressive fluids in continuous processes up to 260°C.

- If you need a higher temperature limit or must seal a worn surface: Consider expanded PTFE (ePTFE), which can operate up to 315°C and provides superior conformability.

- If your application involves high pressure combined with high temperature: Be mindful of PTFE's tendency to creep and investigate filled PTFE grades for improved mechanical stability.

By understanding these properties and trade-offs, you can confidently select the right PTFE gasket to ensure a safe and reliable seal.

Summary Table:

| PTFE Type | Standard Temperature Range | Key Characteristics |

|---|---|---|

| Standard PTFE | -200°C to +260°C | Excellent chemical resistance, standard for most applications |

| Expanded PTFE (ePTFE) | Up to +315°C | Higher temperature limit, superior conformability |

| Filled PTFE | -200°C to +260°C | Improved mechanical stability and wear resistance |

Need a Reliable PTFE Gasket for Extreme Temperatures?

KINTEK specializes in manufacturing high-performance PTFE components, including seals and gaskets, for demanding applications in the semiconductor, medical, laboratory, and industrial sectors. Our expertise ensures you get a sealing solution that delivers:

- Precision Performance: Consistent sealing integrity from cryogenic to high-heat environments.

- Custom Fabrication: Tailored solutions from prototypes to high-volume orders to meet your exact specifications.

- Material Expertise: Guidance on selecting the right PTFE type (standard, ePTFE, filled) for your temperature, pressure, and chemical requirements.

Ensure a safe and reliable seal. Contact our experts today to discuss your project needs!

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Bottles for Diverse Industrial Applications

People Also Ask

- What are the features of split-film PTFE gland packing? A High-Pressure Sealing Solution

- What are the two primary grades of PTFE? Virgin vs. Mechanical for Your Application

- What issue can arise due to PTFE's softness during machining? Mastering Dimensional Accuracy

- How many types of PTFE gaskets are there and what are their general uses? A Guide to Chemical-Resistant Sealing

- What types of surface treatments can be applied to PTFE bushes? Enhance Adhesion for Your Assemblies

- What challenges are associated with constructing PTFE umbilical cords? Mastering Extreme Lengths Without Compromising Purity

- How do PEEK and PTFE compare in terms of friction and chemical compatibility? Choose the Right High-Performance Polymer

- How does the versatility of Teflon plastic sheets benefit different industries? Solve complex engineering challenges