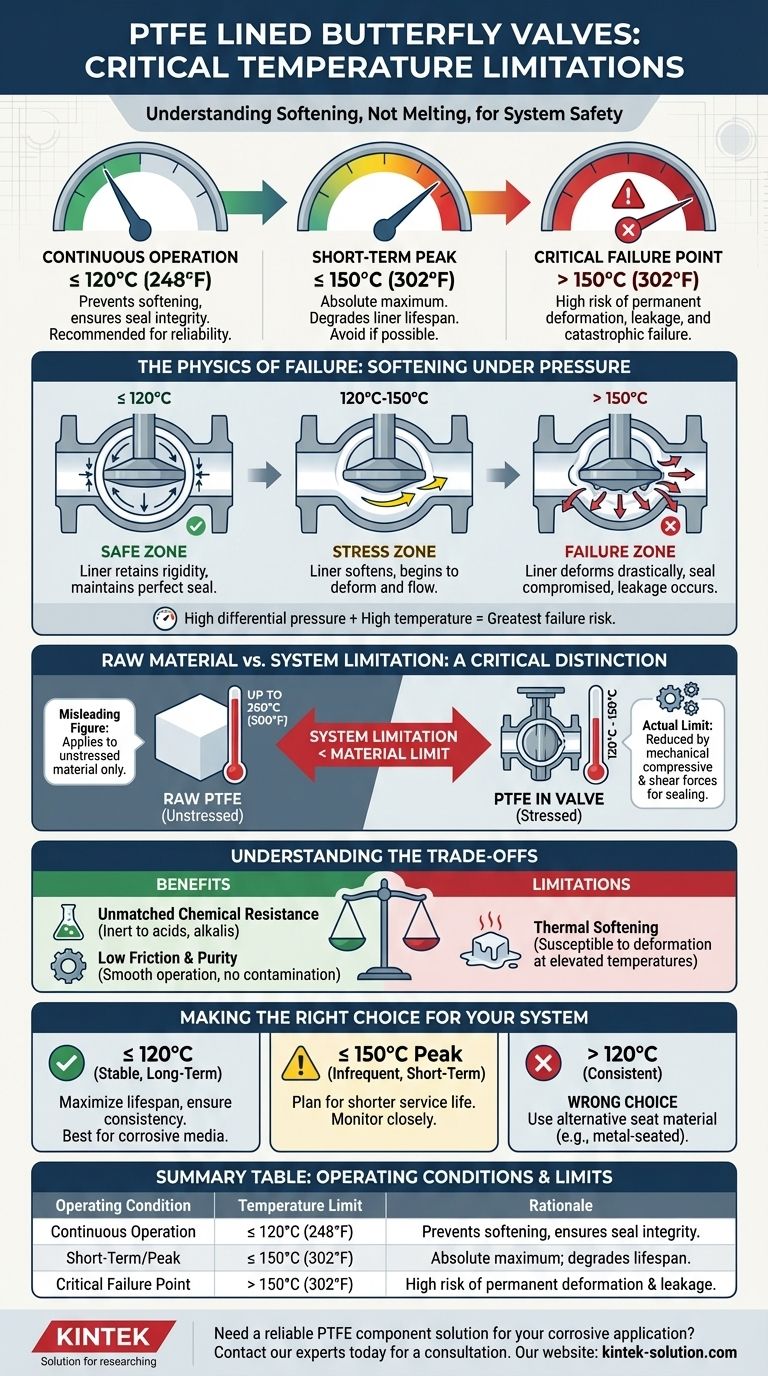

For any PTFE-lined butterfly valve, the absolute maximum temperature of the medium should not exceed 150°C (302°F), and this is only for short, intermittent periods. For reliable, long-term operation and to prevent seal failure, the continuous operating temperature must be controlled at or below 120°C (248°F).

The temperature limit of a PTFE-lined valve is not defined by the melting point of the material, but by the temperature at which it softens and deforms under mechanical pressure, compromising the integrity of the seal. Understanding this distinction is critical to preventing valve failure and leakage.

The Physics of Failure: Why Temperature Limits Are Critical

The operational limits for these valves are rooted in the physical properties of Polytetrafluoroethylene (PTFE) when used as a mechanical seal within a valve body.

The Threshold: 150°C Peak vs. 120°C Continuous

A short-term spike to 150°C may be tolerated, but it introduces stress and begins to degrade the liner's service life.

Continuous operation above 120°C significantly accelerates the softening of the PTFE material, making it the practical and safe upper limit for any system designed for longevity.

The Mechanism of Failure: Softening and Deformation

Unlike metal, PTFE does not fail by cracking or corroding; it fails by deforming. As the temperature rises, the PTFE lining softens and loses its rigidity.

The constant mechanical pressure from the valve disc closing against the liner, combined with the line pressure of the media, will cause a softened liner to extrude or "flow" out of position.

The Consequence: Seal Compromise and Leakage

Once the PTFE liner has deformed, it can no longer create a perfect, bubble-tight seal when the valve is closed. This results in seat leakage, which will only worsen over time.

In severe cases, the deformation can be significant enough to impede the valve's operation or cause a catastrophic failure of the lining, releasing aggressive media.

Raw Material vs. System Application: A Critical Distinction

It is common to see data sheets listing the general temperature resistance of raw PTFE as high as 260°C (500°F). This figure is misleading when applied to a lined valve and is a frequent source of engineering error.

Why Valve Limits Are Lower Than Material Specs

A block of raw, unstressed PTFE can withstand high temperatures. However, inside a valve, the PTFE liner is under constant compressive and shear forces required to create a seal.

This mechanical stress drastically reduces the temperature at which the material begins to deform. The 120°C-150°C limit is a system limitation, not just a material limitation.

The Compounding Effect of Pressure

High differential pressure across the valve exacerbates the problem. The higher the pressure pushing against the disc and seat, the more force is exerted on the softened liner.

Therefore, operating at high temperatures and high pressures simultaneously presents the greatest risk of premature valve failure.

Understanding the Trade-offs of PTFE Linings

Choosing a PTFE-lined valve means accepting a set of engineering trade-offs. Understanding them is key to successful application.

The Benefit: Unmatched Chemical Resistance

The primary reason to select a PTFE-lined valve is its near-total immunity to chemical attack. It is inert to almost all strong acids, alkalis, and solvents, making it essential for corrosive service.

The Benefit: Low Friction and Purity

PTFE's extremely low coefficient of friction ensures smooth, low-torque valve operation. Its inherent purity also makes it suitable for applications where media contamination is a concern.

The Inherent Limitation: Thermal Softening

The chief trade-off for these benefits is a relatively low operating temperature compared to metal-seated valves. The susceptibility to thermal softening and deformation is the valve's defining limitation.

Making the Right Choice for Your System

Base your valve selection and operational parameters on the realities of your process conditions to ensure safety and reliability.

- If your primary focus is stable, long-term service with corrosive media: Design your system to operate consistently at or below 120°C (248°F) to maximize the valve's lifespan.

- If your process involves unavoidable, short-term temperature spikes: Ensure these excursions never exceed 150°C (302°F) and happen infrequently, and plan for a shorter valve service life.

- If your operating temperature will consistently exceed 120°C: A PTFE-lined butterfly valve is the wrong choice. You must specify a valve with a different seat material, such as a high-performance or metal-seated butterfly valve.

Ultimately, respecting the thermal limitations of the valve's sealing system is fundamental to safe and effective process control.

Summary Table:

| Operating Condition | Temperature Limit | Rationale |

|---|---|---|

| Continuous Operation | ≤ 120°C (248°F) | Prevents softening/deformation of PTFE liner under mechanical stress, ensuring long-term seal integrity. |

| Short-Term/Peak | ≤ 150°C (302°F) | Absolute maximum for brief periods; introduces stress and degrades liner lifespan. |

| Critical Failure Point | > 150°C (302°F) | High risk of permanent liner deformation, seat leakage, and catastrophic valve failure. |

Need a reliable PTFE component solution for your corrosive application?

Understanding the precise thermal and mechanical limits of your components is critical to system safety and longevity. At KINTEK, we specialize in the custom fabrication of high-performance PTFE components—including seals, liners, and labware—for the semiconductor, medical, laboratory, and industrial sectors.

We prioritize precision manufacturing to ensure your components perform reliably within their specified parameters, helping you avoid costly downtime and failures.

Let us help you select or custom-design the right PTFE solution for your specific temperature and pressure requirements.

Contact our experts today for a consultation

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

- Custom PTFE Square Trays for Industrial and Laboratory Use

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

People Also Ask

- What are the additional characteristics of PTFE rods? Unlock Superior Performance in Harsh Environments

- How does the PTFE lining in diaphragm valves enhance performance? Boost Reliability in Harsh Chemical Processes

- What should be considered when milling Teflon? Master Machining for Precision PTFE Parts

- What is a Teflon seal and what material is it made from? Unlock Superior Performance in Harsh Environments

- What temperature range can ePTFE gaskets operate within? Seal from -200°C to 315°C

- How does selecting the right PTFE Expansion Bellow benefit a piping system? Enhance System Longevity and Safety

- What are the key design features of PTFE bushings? Achieve Maintenance-Free, High-Performance Bearing Solutions

- Why is low friction important in PTFE seals? Extend Lifespan and Boost Efficiency