In essence, PTFE gaskets are safe for sensitive applications because the material is chemically inert and non-toxic. This means PTFE does not react with, break down into, or otherwise contaminate the substances it comes into contact with, making it a trusted choice for industries like food processing, pharmaceuticals, and medical devices.

PTFE’s value comes from its fundamental chemical stability. Because it does not contaminate or react with its environment, it provides a pure and reliable seal, but its physical limitations mean it is not a universal solution for every high-performance scenario.

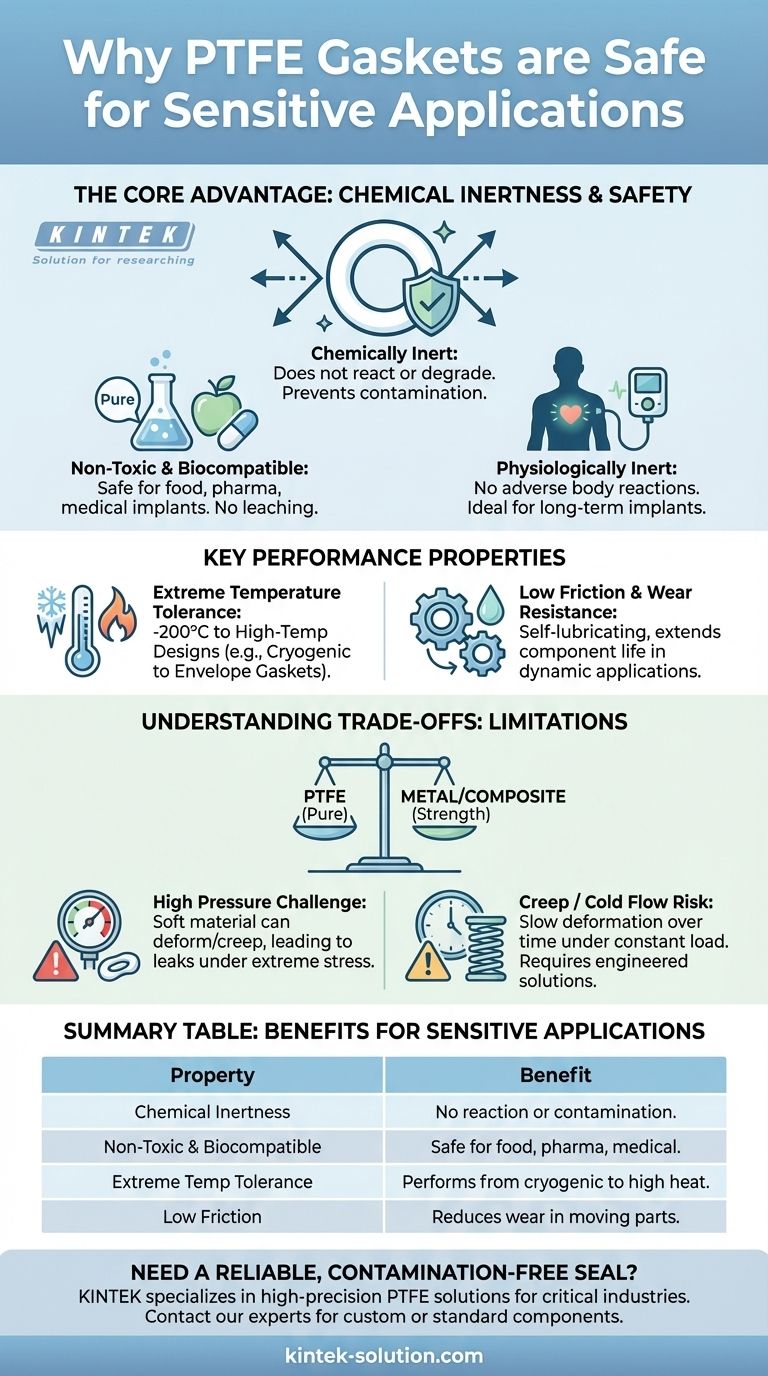

The Foundation of PTFE Safety: Chemical Inertness

The primary reason PTFE is specified for sensitive environments is its unique chemical makeup. This inherent stability is the source of its safety and reliability.

What "Inert" Means for Your Application

A chemically inert material does not participate in chemical reactions with other substances. For a gasket, this is a critical property.

It ensures that the seal itself will not degrade when exposed to aggressive chemicals, nor will it introduce unwanted contaminants into the system it is sealing.

Preventing Contamination in Food and Pharma

In food processing and pharmaceutical manufacturing, even trace amounts of contamination can ruin a batch or violate health regulations.

PTFE's non-toxic and inert nature guarantees that no harmful substances will leach from the gasket into the product, preserving its purity and ensuring compliance.

Biocompatibility in Medical Devices

Beyond being non-toxic, PTFE is also physiologically inert, or biocompatible.

The material shows no adverse reactions when used within the human body. This has made it a benchmark material for long-term medical implants, including artificial organs and blood vessels.

Key Performance Properties Supporting Reliability

While chemical safety is paramount, PTFE's physical properties also contribute to its performance in demanding applications, from cryogenic systems to aerospace engines.

Extreme Temperature Tolerance

PTFE maintains its integrity across a vast temperature spectrum. It performs exceptionally well in cryogenic conditions as low as -200°C (-328°F), making it ideal for liquefied gas storage and transport.

Conversely, specialized designs like PTFE envelope gaskets are engineered to handle high temperatures by minimizing creep and maintaining a precise, reliable seal.

Low Friction and Wear Resistance

PTFE has one of the lowest coefficients of friction of any solid material. This self-lubricating property is vital in applications with moving parts, such as dynamic seals or bearings.

It reduces wear and heat generation, which increases the operational life and reliability of the component, a key factor in high-stakes industries like aerospace.

Understanding the Trade-offs: When PTFE Is Not the Right Choice

No single material is perfect for every situation. Understanding PTFE's limitations is crucial for proper material selection and avoiding seal failure.

The Challenge of High Pressure

The primary weakness of standard PTFE is its performance under very high pressure. The material is relatively soft and can deform, extrude, or "creep" out of its flange under extreme mechanical stress.

In high-pressure systems, this deformation can lead to leaks. For these applications, metal gaskets are often the superior choice due to their inherent strength and resistance to mechanical load.

The Risk of Creep or "Cold Flow"

"Creep" or "cold flow" is the tendency of PTFE to slowly deform over time when subjected to a constant compressive load.

This can be a problem in static seals that must maintain a consistent clamping force over a long service life. While engineered PTFE variants mitigate this, it remains a fundamental characteristic to consider during design.

Making the Right Choice for Your Goal

Selecting the correct gasket requires balancing the need for chemical purity against the physical demands of the operating environment.

- If your primary focus is absolute purity and biocompatibility: PTFE is an industry-standard choice due to its inert, non-toxic, and non-contaminating properties.

- If your application involves extreme high pressure: Carefully evaluate PTFE's pressure limits and consider metal or composite gaskets for superior mechanical strength.

- If your system operates at temperature extremes: Verify the specific PTFE type, as standard grades excel in cryogenic cold while specialized envelope gaskets are better suited for heat.

Ultimately, understanding both the chemical strengths and physical limitations of PTFE empowers you to design a safe and reliable system.

Summary Table:

| Property | Benefit for Sensitive Applications |

|---|---|

| Chemical Inertness | Does not react with or contaminate process media. |

| Non-Toxic & Biocompatible | Safe for food, pharmaceuticals, and medical implants. |

| Extreme Temperature Tolerance | Performs from -200°C to high-temp designs. |

| Low Friction | Reduces wear in dynamic applications. |

Need a reliable, contamination-free seal for your sensitive application?

KINTEK specializes in manufacturing high-precision PTFE components, including seals and gaskets, for the semiconductor, medical, laboratory, and industrial sectors. We understand the critical need for purity and performance.

Whether you require a standard solution or a custom-fabricated part from prototype to high-volume production, our expertise ensures your system's integrity and compliance.

Contact our experts today to discuss your specific requirements and how we can support your project's success.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Customizable PTFE Seals Filter Holders for Versatile Applications

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

People Also Ask

- Why are PTFE lined ball valves suitable for the food and pharmaceutical industries? Ensuring Purity and Compliance

- Where are PTFE energized seals used in oil and gas operations? Essential Sealing Solutions for Harsh Environments

- What are the key steps for properly installing PTFE gaskets? Ensure a leak-free seal with our expert guide.

- What makes machined PTFE suitable for industrial applications? Unmatched Performance in Extreme Conditions

- What are the main types of PTFE lined valves? Find the Right Valve for Your Corrosive Application

- Why is PTFE difficult to process using traditional methods? Overcoming High Melt Viscosity

- What are the applications of PTFE V-Rings? Sealing Solutions for Extreme Environments

- What industries commonly use Teflon washers? Unlock Versatile Sealing Solutions