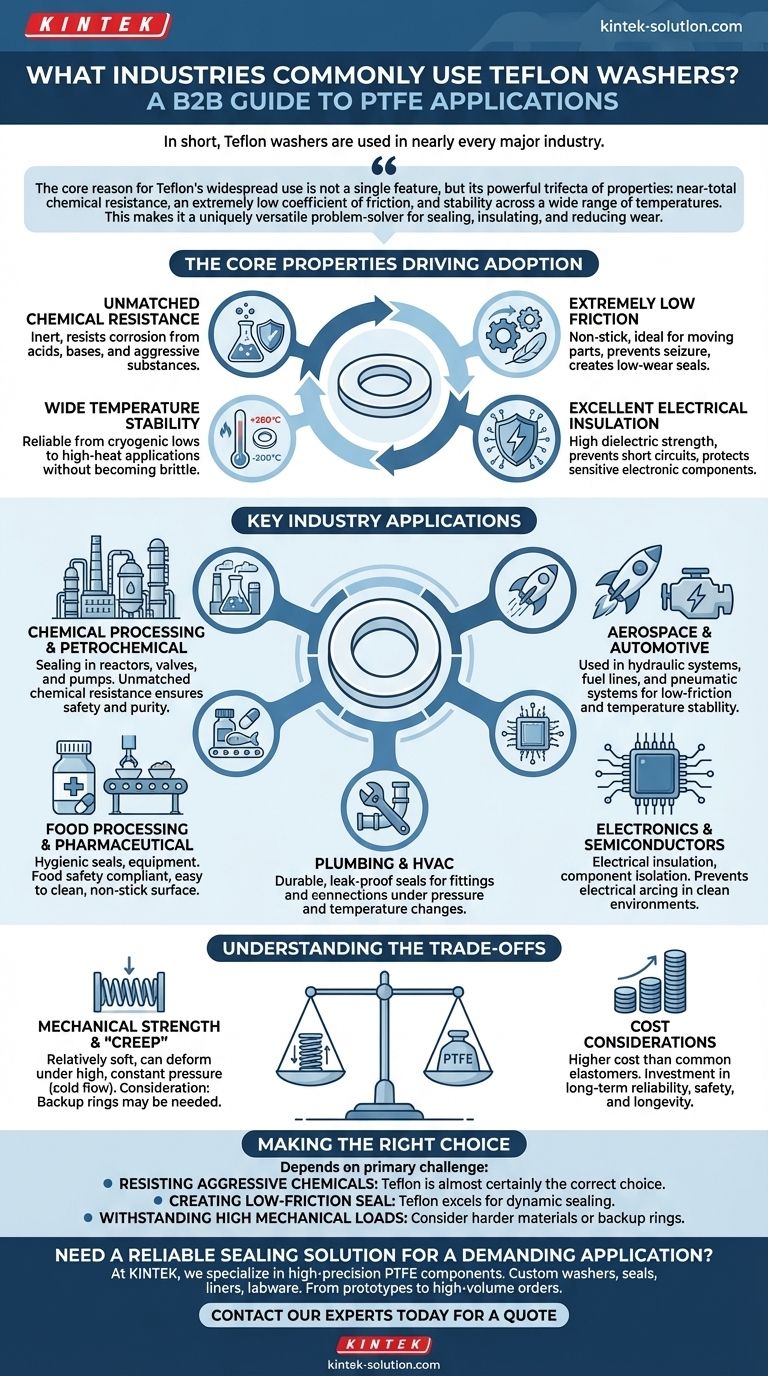

In short, Teflon washers are used in nearly every major industry. Their application is remarkably broad, spanning from aerospace and chemical processing to food manufacturing, electronics, and automotive sectors due to a unique combination of material properties.

The core reason for Teflon's widespread use is not a single feature, but its powerful trifecta of properties: near-total chemical resistance, an extremely low coefficient of friction, and stability across a wide range of temperatures. This makes it a uniquely versatile problem-solver for sealing, insulating, and reducing wear.

The Core Properties Driving Adoption

To understand why so many industries rely on Teflon (PTFE), we must first look at its fundamental characteristics. These properties solve common engineering challenges that other materials cannot.

Unmatched Chemical Resistance

Teflon is famously inert, meaning it resists corrosion and degradation from the vast majority of chemicals, acids, and bases. This makes it an essential material for any environment involving aggressive substances.

Extremely Low Friction

Often called one of the most slippery materials in existence, Teflon has an exceptionally low coefficient of friction. This "non-stick" quality is ideal for moving parts, preventing seizure, and creating reliable, low-wear seals.

Wide Temperature Stability

Teflon performs reliably across a broad spectrum of temperatures, from cryogenic lows to high-heat applications. This thermal stability ensures that washers and seals maintain their integrity without becoming brittle or deforming under extreme conditions.

Excellent Electrical Insulation

As a material with high dielectric strength, Teflon does not conduct electricity. This makes it an ideal insulator, preventing short circuits and protecting sensitive components in electrical and electronic applications.

Key Industry Applications in Detail

These core properties translate directly into practical uses across diverse and demanding sectors.

Chemical Processing & Petrochemical

In environments filled with corrosive materials, such as reactors, valves, and pumps, Teflon's chemical inertness is non-negotiable. It provides a reliable seal that won't degrade, ensuring both safety and process purity.

Aerospace & Automotive

The aerospace and automotive industries value reliability under stress. Teflon washers are used in hydraulic systems, fuel lines, and pneumatic systems for their low-friction sealing and resistance to aggressive fluids and temperature fluctuations.

Food Processing & Pharmaceutical

Safety and hygiene are paramount in these fields. Teflon is compliant with food safety regulations and easy to clean. Its non-stick surface prevents buildup, and its chemical resistance stands up to harsh cleaning agents.

Electronics & Semiconductors

Here, Teflon's role as an electrical insulator is critical. It is used to isolate components, prevent electrical arcing, and provide sealing in equipment where both cleanliness and electrical integrity are required.

Plumbing & HVAC

In everyday plumbing and HVAC systems, Teflon provides durable, long-lasting seals. Its ability to create a low-friction, leak-proof barrier makes it a staple for fittings and connections that must withstand constant pressure and temperature changes.

Understanding the Trade-offs

While incredibly versatile, Teflon is not the solution for every single application. Objectivity requires acknowledging its limitations.

Mechanical Strength and "Creep"

Compared to metals or harder plastics, Teflon is a relatively soft material. Under high, constant pressure (compressive load), it can be susceptible to "creep" or cold flow, where the material slowly deforms over time.

Cost Considerations

Teflon is a high-performance polymer, and its cost is generally higher than that of common elastomers like rubber or other plastics. The choice to use it is often a deliberate investment in reliability, safety, and longevity for a specific application.

Making the Right Choice for Your Application

Selecting the right material depends entirely on the primary challenge you need to solve.

- If your primary focus is resisting aggressive chemicals: Teflon is almost certainly the correct choice due to its near-universal chemical inertness.

- If your primary focus is creating a low-friction seal: Teflon excels at providing a slippery, non-stick surface for dynamic sealing applications or preventing parts from galling.

- If your primary focus is withstanding high mechanical loads: You may need to consider a harder material or use Teflon in conjunction with a more rigid backup ring.

Ultimately, the ubiquity of Teflon washers is a direct result of their power to solve critical engineering problems where other materials fail.

Summary Table:

| Industry | Primary Use of Teflon Washers | Key PTFE Property Utilized |

|---|---|---|

| Chemical Processing | Sealing in reactors, valves, and pumps | Unmatched chemical resistance |

| Aerospace & Automotive | Hydraulic systems, fuel lines | Temperature stability, low friction |

| Food & Pharmaceutical | Hygienic seals, equipment | Chemical inertness, non-stick surface |

| Electronics & Semiconductors | Electrical insulation, component isolation | Excellent dielectric strength |

| Plumbing & HVAC | Leak-proof fittings and connections | Durability, wide temperature stability |

Need a reliable sealing solution for a demanding application?

At KINTEK, we specialize in manufacturing high-precision PTFE components, including custom Teflon washers, seals, liners, and labware. Whether you're in the semiconductor, medical, laboratory, or industrial sector, we provide the material expertise and precision production—from prototypes to high-volume orders—to ensure your components perform flawlessly under extreme conditions.

Contact our experts today to discuss your specific requirements and get a quote!

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Customizable PTFE Seals Filter Holders for Versatile Applications

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

People Also Ask

- What are the material advantages of machining Teflon? Unlock Unmatched Chemical & Thermal Resistance

- What is PTFE commonly known as and what are its unique properties? Unlock Unmatched Chemical & Thermal Resistance

- What are some common applications of machined PTFE? Leverage its Unique Properties for Demanding Applications

- What are the primary applications of PTFE fasteners and custom parts? Critical Solutions for Extreme Environments

- Why is PTFE suitable for cryogenic or high-temperature applications? Unmatched Thermal Stability from -450°F to 500°F